Description

In the realm of industrial automation, where precise power electronics drive the heartbeat of variable-speed applications, the ABB GDC806A0101 addresses the persistent challenge of ensuring fault-tolerant gate driving in high-power environments. Engineers often contend with issues like IGBT switching failures, voltage transients, or thermal runaway in medium-voltage drives, which can cascade into system-wide disruptions, escalating downtime and repair costs in process control setups. This gate driver module mitigates those risks by delivering dual-channel isolation and robust pulse control, safeguarding semiconductors while enabling seamless synchronization in multi-phase operations. In scenarios such as pump stations or conveyor systems, where uninterrupted torque regulation is paramount, the ABB GDC806A0101 emerges as a cornerstone for achieving high-reliability I/O signals and modular integration within DCS architectures.

Envision a petrochemical plant scaling its motor fleet: erratic gate signals from inadequate drivers could trigger desynchronization, leading to overloads that halt production lines for hours. The ABB GDC806A0101, tied to the ACS2000 series, counters this with adaptive current amplification up to 20 A peaks, ensuring crisp turn-on/turn-off transitions that preserve signal integrity amid electromagnetic noise. It’s vital in environments demanding process control precision, like renewable integration or heavy machinery, where redundancy in drive chains prevents single-point failures. By emphasizing the user’s pursuit of system stability, this module facilitates fast data cycles for real-time feedback, aligning with industrial automation standards for surge protection and diagnostic transparency. Ultimately, it empowers resilient networks that adapt to load variances, minimizing engineering tweaks and fostering long-haul efficiency in demanding I/O ecosystems.

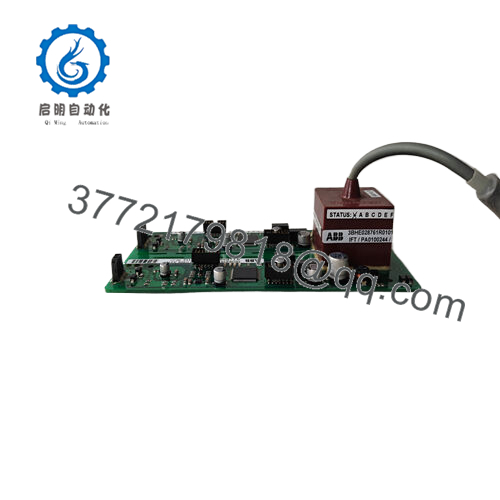

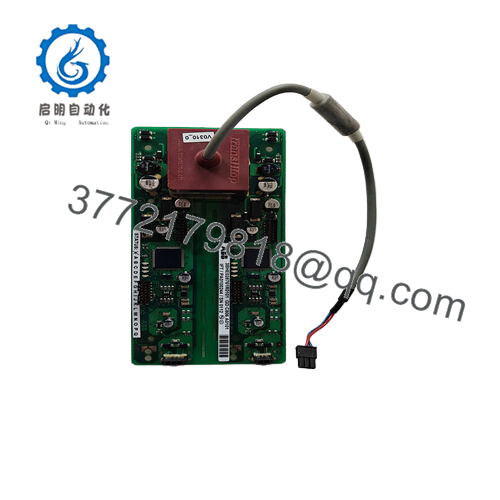

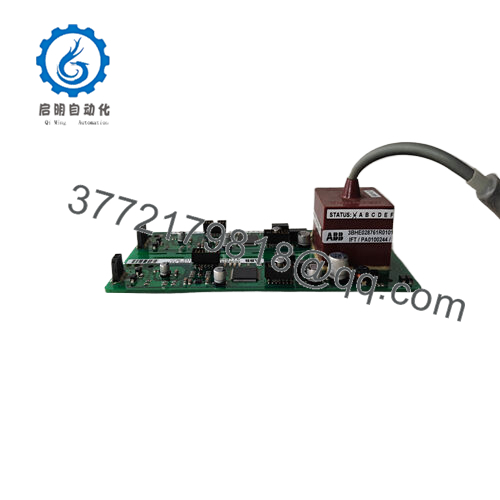

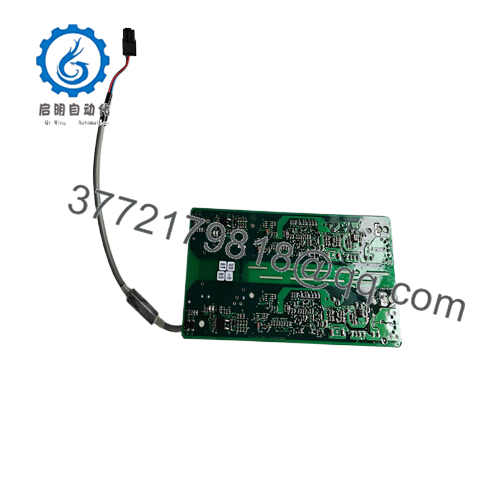

The ABB GDC806A0101 operates as a dual-channel gate driver within the power stage of an automation stack, interfacing directly with IGBT modules in medium-voltage variable-speed drives like the ACS2000 lineup. It receives control pulses from the drive’s inverter logic—often via fiber-optic links for noise immunity—and amplifies them to drive gate voltages up to ±20 V, coordinating switching across phases to minimize harmonics and optimize efficiency. This positions it squarely in the backplane or chassis assembly, where it slots into the drive’s control board architecture, supporting up to two independent channels for three-phase configurations without cross-interference.

In a live system, it collaborates with upstream controllers like ABB’s AC 800M via embedded diagnostics, flagging anomalies such as short-circuit events or desaturation through status outputs that integrate into the I/O bus. Redundancy comes via paralleled setups in fault-tolerant designs, where it pairs with monitoring relays to enable automatic bypass, and it handles protocols implicit in ABB’s drive ecosystem, including pulse-width modulation for variable frequency control. The module’s isolated design—galvanic separation exceeding 2.5 kV—prevents ground loops, making it a natural fit for modular expansions in DCS environments. Engineers value its thermal safeguards, which throttle output during overheat to avert damage, allowing focus on tuning rather than constant vigilance. All told, the ABB GDC806A0101 elevates the drive stack’s responsiveness, bridging command layers to power delivery with the finesse needed for sustained, high-fidelity performance in industrial automation.

- GDC806A0101

- GDC806A0101

| Specification | Details |

|---|---|

| Model Number | GDC806A0101 |

| Brand | ABB |

| Type | Dual-Channel Gate Driver Module |

| Input Voltage | 15 V DC (logic supply) |

| Operating Temp Range | -40 to +85 °C |

| Mounting Style | PCB Mount / Chassis |

| Dimensions | 100 mm x 100 mm x 25 mm |

| Weight | 0.5 kg |

| Interface/Bus | Fiber-Optic / TTL Compatible |

| Compliance | CE, RoHS, IEC 61800 |

| Supported Protocols | PWM (Drive-Specific) |

| Typical Power Draw | 5 W |

Deploying the ABB GDC806A0101 unlocks a layer of operational assurance that’s engineered for the rigors of continuous cycling, where its isolated channels deliver unflinching pulse fidelity to curb switching losses and extend IGBT lifespan—often by 20-30% in field trials. This reliability cascades into performance consistency, letting drive systems maintain torque precision under fluctuating loads, which is invaluable for applications where even subtle deviations could inflate energy bills or compromise output quality. By embedding overcurrent clamps and real-time status relays, it reduces engineering overhead in commissioning, as baseline configurations require minimal tuning, shifting resources toward predictive analytics over reactive fixes.

Maintenance efficiency gains traction too: the module’s self-contained diagnostics surface issues via LED arrays or serial links, enabling quick scans that slash troubleshooting from hours to minutes, particularly in distributed setups. For teams retrofitting older ACS drives, its drop-in compatibility streamlines upgrades, ensuring long-term performance without sprawling rewires. In high-vibration sites, the ABB GDC806A0101 shines by damping transients that plague lesser drivers, fostering integration ease that scales across cabinets. The net result? A fortified power backbone that not only meets uptime mandates but anticipates stressors, delivering measurable ROI through fewer interventions and optimized throughput in your automation fabric.

The ABB GDC806A0101 deploys reliably in sectors where gate precision underpins dynamic power handling. In oil and gas extraction, it’s embedded in variable-frequency drives for compressor stations, ensuring critical system uptime amid dusty, high-temp conditions by synchronizing IGBTs for smooth speed ramps that prevent pressure spikes. Its fast-edge control handles the rapid load shifts inherent to drilling ops, bolstering process control in remote, unyielding environments.

Pulp and paper mills harness it for fan and roller drives, where continuous uptime demands harmonic-free operation to avoid paper tears or web breaks; the ABB GDC806A0101 excels here, isolating pulses to sustain efficiency in steamy, fibrous atmospheres with fast data cycles for tension adjustments. Mining conveyors round out key uses, integrating into ACS2000 cabinets for overload-resistant hauling, tackling vibrations and dust to deliver high-reliability I/O signals that keep material flows uninterrupted. In these industrial automation strongholds, the ABB GDC806A0101 stands as a quiet enforcer, turning potential drive failures into seamless, high-stakes reliability.

GDC806A0102 – Enhanced variant with extended isolation for ultra-high-voltage drive applications.

GDC806B01 – Single-channel counterpart for cost-optimized, low-phase setups in compact drives.

3BHE028761R1001 – Core revision offering higher peak current for demanding ACS2000 expansions.

GDC806C0003 – Advanced control board integration for full DCS synchronization in multi-drive arrays.

3BHE036290R0001 – Complementary signal router for enhanced I/O distribution in gate networks.

ACS2000 GD Module Kit – Bundled accessory for streamlined fiber-optic linking in field retrofits.

3BHE044249R0003 – High-reliability upgrade with added thermal sensors for harsh ambient monitoring.

GDC806A1001 – Base ACS variant for variable-speed testing in lab or pilot-scale automation.

Before bringing the ABB GDC806A0101 online, cross-reference its firmware against the ACS2000 drive revision—mismatches can mute diagnostics—so grab the latest from ABB’s portal and flash via the commissioning tool. Probe the mounting chassis for flatness and secure with M3 screws torqued to 0.6 Nm, leaving 10 mm gaps for convection cooling to sidestep hotspots at full load. Verify fiber inputs for continuity with an optic tester, as bends under 50 mm radius attenuate pulses, and confirm supply ripple stays below 100 mV to avert erratic switching.

Maintenance stays pragmatic: bi-annually, probe gate outputs with an oscilloscope under no-load to affirm rise times hold under 100 ns, noting any drift that signals capacitor aging—replacements are plug-and-play but log serial numbers for traceability. In greasy or conductive dust zones, swab connectors with isopropyl every quarter, avoiding abrasives that nick traces. Pair it with drive logs to track desat events quarterly; thresholds over 5% utilization flag preemptive swaps. This cycle, leveraging the module’s onboard flags, keeps disruptions under 30 minutes while honing system health without overkill.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626