Description

Real-World Use & Application Scenarios

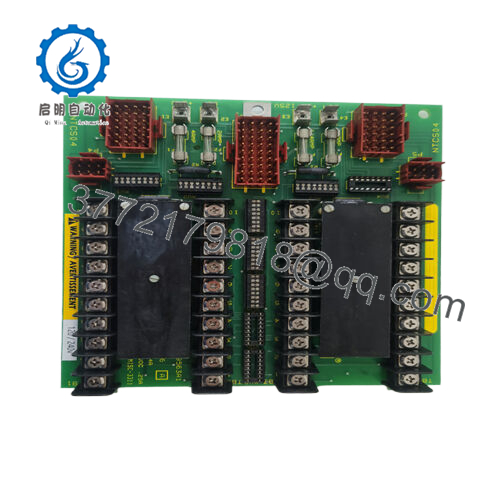

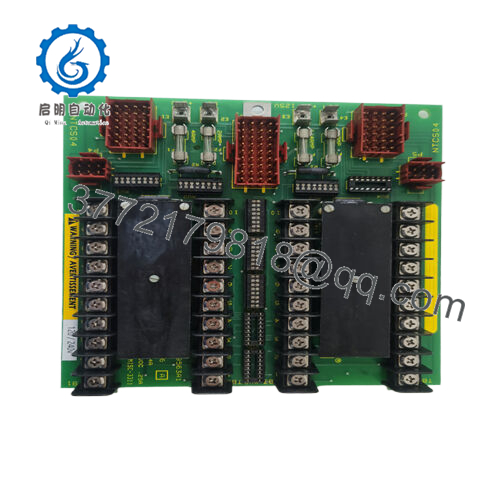

Where is this product used and why? In many factories and process plants, the ABB NTCS04 acts as the essential bridge between the control logic and the field devices that actually move and measure the process. It’s a compact termination/IO unit that consolidates digital and analog I/O connections, routing signals from sensors and actuators to the central controller with reliable isolation and clean grounding. In automotive, chemical, petrochemical, food and beverage, and energy facilities, you’ll find NTCS04 deployed at cabinet enclosures or machine panels to simplify wiring, reduce fault propagation, and improve diagnostic visibility. It supports key tasks like signal conditioning, discrete and analog I/O interfacing, and safe termination for fieldbus or PLC networks. Practically, engineers rely on this module to shorten commissioning, improve signal integrity in noisy environments, and provide a stable interface for safety interlocks and control monitoring. In the ABB Symphony Harmony INFI 90 landscape, the NTCS04 is commonly described as a control I/O termination unit that keeps field devices neatly integrated with the controller hierarchy. When discussing this model in procurement briefs, the full model name should appear in bold: ABB NTCS04.

Product Introduction & Positioning

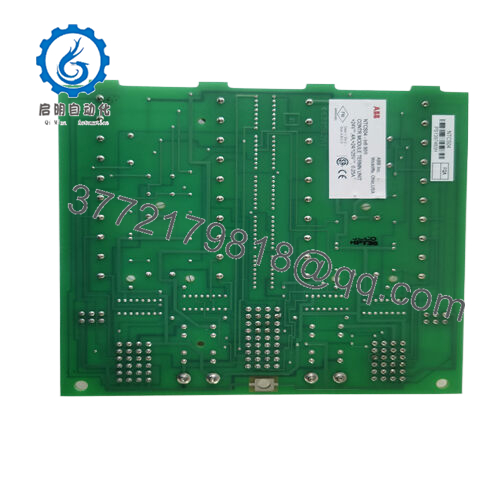

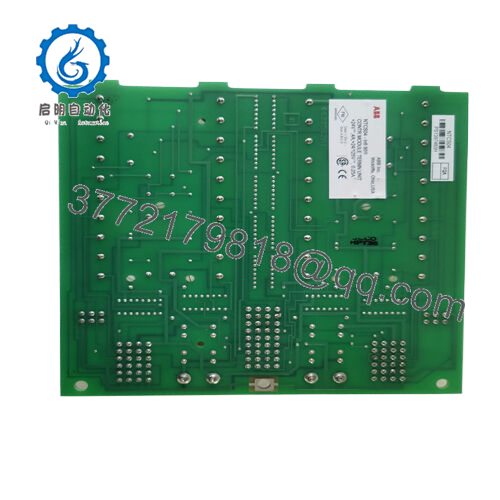

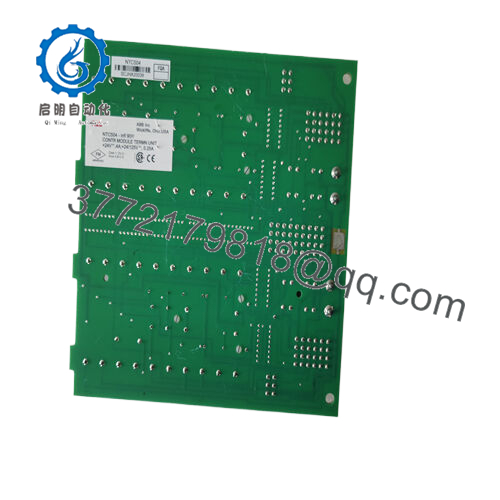

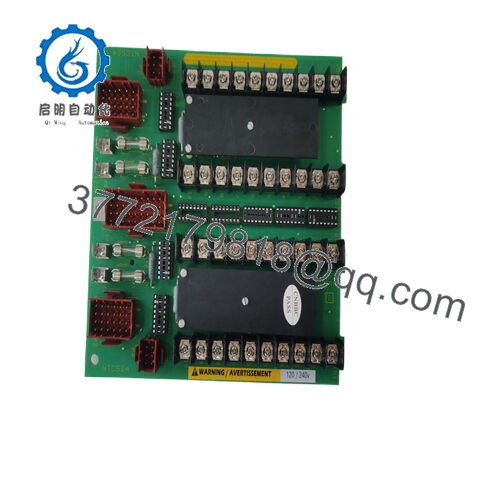

The ABB NTCS04 is a rugged control I/O termination unit designed to interface ABB automation platforms with field devices. It sits at the edge of the automation system, acting as a compact hub that consolidates I/O wiring, provides necessary isolation, and translates field signals into a form usable by the central controller or DCS. This module is typically integrated into Symphony Harmony INFI 90 or compatible control architectures, where it contributes to a scalable, modular I/O backbone. Its value lies in reliable signal termination, straightforward mounting in standard enclosures, and robust operation in industrial environments with EMI considerations and varying supply voltages. The model is frequently cited as a dependable building block for retrofit projects and new installations alike, offering predictable behavior across a range of industrial applications. In documentation and configuration, emphasize the exact designation: ABB NTCS04.

- NTCS04

- NTCS04

Key Technical Features & Functional Benefits

The ABB NTCS04 provides strong functional performance through reliable signal termination, clean I/O lace, and compatibility with both analog and digital signals. Its rugged enclosure and compact footprint support integration in tight panel spaces while maintaining appropriate clearance for cooling and maintenance. The hardware design emphasizes isolation between field devices and control electronics, reduced wiring complexity, and straightforward diagnostics via status indicators or built-in testing features. It’s designed to accommodate common industry protocols and mounting schemes, supporting flexible deployment in existing cabinets or new installations. Long-term reliability is reinforced by durable materials, protection against environmental factors, and a layout that facilitates routine checks and firmware validations. Together, these attributes help engineers achieve consistent control loop performance and easier troubleshooting across a plant’s automation network.

Detailed Technical Specifications

| Parameter | Value |

| Model | NTCS04 |

| Brand | ABB |

| Type | Control I/O Termination Unit |

| Power Supply | 24 VDC typical (±)

| Operating Temperature | 0 to 60°C (typical) |

| Mounting | DIN rail or panel mounting (specifics may vary) |

| Dimensions | Approximately 20.3 cm x 2.5 cm x 17.8 cm |

| Weight | ~0.4–0.8 kg (varies by configuration) |

| Interfaces | Digital I/O, Analog I/O, fieldbus/PLC interface (as configured) |

| Certifications | CE, potentially UL/CSA depending on batch and region |

| Cooling | Natural convection with enclosure ventilation |

| Environmental Rating | NEMA/IEC enclosure protection suitable for industrial environments |

Related Modules or Compatible Units

- NTCS03 — Same family, supports a slightly different I/O mix or voltage range.

- NTCS05 — Next-generation variant with expanded I/O counts and faster diagnostics.

- NTCS04A — An enhanced revision with improved EMI shielding and mounting options.

- NTDI01 — Digital I/O Terminal Unit with a compatible interface for legacy ABB systems.

- NTDI02 — Digital/Analog I/O termination unit with alternative power-supply options.

- NTCS04-Plus — Higher-capacity version for denser cabinet configurations.

- NTCS04-R — Ruggedized variant optimized for vibration-prone machinery.

- NTCS04-HeavyDuty — Industrial-harsh environment variant with reinforced housing.

- Installation Notes & Maintenance Best Practices

Pre-installation considerations include ensuring the cabinet layout accommodates the NTCS04’s footprint and allows unobstructed air paths for cooling, along with proper cable-entry provisions and strain relief. Grounding strategies should prioritize correct bonding of the chassis while maintaining signal-ground isolation where the system requires it. Verify gasket seals and enclosure ratings match the environmental exposure, especially in washdown or dust-prone areas. Plan cable routing to minimize cross-talk by separating power and signal conductors, and ensure that shielded cables are terminated properly. Before power-up, confirm the power budget can handle peak loads and that surge protection is in place. Post-installation, schedule quarterly visual inspections for loose connectors, signs of wear, and corrosion, with semi-annual signal diagnostics to verify I/O accuracy. Establish a firmware update policy and keep a tested spare module for rapid replacement. Maintain a changelog of maintenance actions and ensure documentation is readily accessible to operators and technicians.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626