Description

What This Product Solves

In precision process control and production measurement, robust load-cell interfaces and reliable signal conditioning are essential. The PFTL101A-2.0KN PillowBlock Load Cell family is designed to deliver accurate force measurement in demanding industrial settings, where tension, weight, or force needs to be monitored with minimal drift and high repeatability. This variant targets applications requiring 2.0 kN of capacity, with performance characteristics suited to paper, textile, or packaging lines, where consistent sensor output translates into stable control actions. The device typically lives in centralized measurement loops or in line-mounted weighing or tensioning systems, where a compact form factor and dependable signal integrity are crucial. By providing precise measurement and rugged construction, it supports higher process visibility, easier calibration, and fewer rework cycles due to measurement anomalies. In short, it’s a reliable building block for measurement accuracy, process control fidelity, and long-term stability in automated environments.

How the Product Works & Fits into a System

The PFTL101A-2.0KN is a pillowblock load cell designed to convert mechanical tension or force into an electrical signal that a controller can interpret. It integrates into machine frames or support structures and interfaces with measurement electronics, amplifiers, or a controller that aggregates force data for feedback loops. Depending on configuration, it may require a signal conditioning stage and cabling that preserves signal integrity in the presence of vibration or EMI. The module’s footprint is typically optimized for installation in line segments or monitoring stations, making it straightforward to deploy in existing equipment without large design changes. In system terms, it acts as the sensor backbone for force measurement, providing aligned data to the control system to influence process parameters, safety interlocks, or product quality decisions. The model designation anchors product selection, replacement planning, and maintenance workflows across sites using ABB’s measurement solutions.

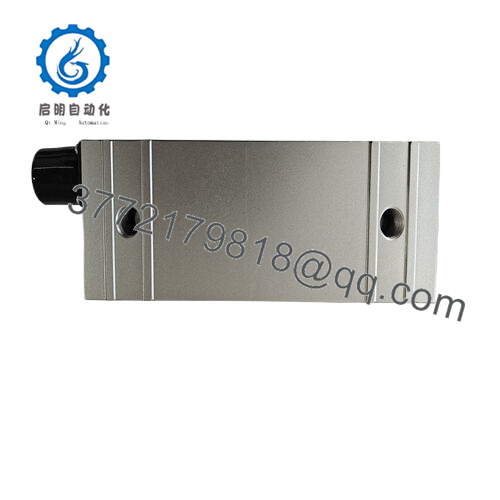

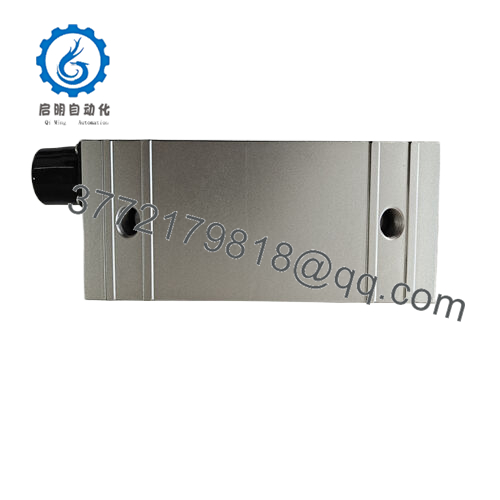

- PFTL101A-2.0KN 3BSE004172R1

- PFTL101A-2.0KN 3BSE004172R1

Technical Highlights Summary

Model Number PFTL101A-2.0KN 3BSE004172R1

Brand ABB

Type Pressductor pillowblock load cell

Capacity 2.0 kN

Measurement Principle Magnetic inductive (Pressductor)

Output Analog signal proportional to force (voltage/current specification to be confirmed)

Rated Excitation Typically 5–10 V or 12–24 V DC (variant-dependent)

Output Sensitivity Calibrated to target force range (exact mV/V or mA specification to confirm)

Mounting Style Pillowblock

Electrical Connection Cable or connector variant dependent

Enclosure Rating IP rating variant dependent

Operating Temperature Variant-dependent

Certifications CE RoHS (confirm region-specific)

Current Draw Minimal (conditioned by amplifier/trace wiring)

Real-World Benefits

Choosing the PFTL101A-2.0KN delivers precise force measurement in a compact form factor, engineered to minimize drift and maximize repeatability over time. Its robust construction supports stable readings in vibration-prone environments and helps reduce calibration overhead by offering reliable baseline outputs. With consistent sensor performance, maintenance teams can schedule targeted inspections and minimize downtime due to measurement drift or sensor failure. The model designation becomes a familiar anchor in measurement and quality documentation, enabling straightforward replacement planning and cross-site standardization. In practice, users gain improved process visibility, more predictable force-driven control actions, and a reduction in rework caused by measurement uncertainties.

Typical Use Cases

2.0 kN pillowblock load cells are commonly employed in packaging and converting lines, tension control for rolls and webs, and precision weighing scenarios where force measurements drive process decisions. They are suitable for paper and pulp, textile, and plastics applications where accurate tension or load sensing improves product consistency, roll control, and machine performance. The compact form factor and robust signal characteristics make them a practical choice for retrofit projects or new installations in industrial environments that demand reliable, repeatable force data.

Compatible or Alternative Products

PFTL101A-2.0KN 3BSE004172R1 – Base 2.0 kN pillowblock load cell

PFTL101A-5.0KN – Higher capacity variant for heavier loads

PFTL101A-1.0KN – Lower capacity variant for lighter loads

PFTL101B-2.0KN – Revised sensing element with improved sensitivity

PFTL101A-2.0KN-DIN – DIN-rail compatible mounting option

PFTL101A-2.0KN-IP65 – Higher IP rating for harsher environments

PFTL101A-2.0KN-EXT – Extended cable length version

PFTL101A-2.0KN-AMP – With integrated amplification electronics

Setup Notes & Maintenance Insights

Before installation, verify the exact variant’s electrical and mechanical requirements, including excitation voltage, output signaling, and mounting tolerances. Confirm mating connectors and cabling lengths to ensure signal integrity in the target environment. During commissioning, calibrate against known weights or loads and document the calibration constants for future maintenance. Regular maintenance should include visual inspection of mounting hardware for alignment, checking for signs of creep or misalignment under load, and periodic verification of output against reference standards. Maintain an up-to-date spare-parts kit for connectors and mounting hardware. Document installation baselines and keep traceability data for audits and quality systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626