Description

In the world of industrial automation, where precise signal handling can mean the difference between seamless operations and costly disruptions, engineers often grapple with the need for versatile I/O interfaces that handle both analog and digital signals without compromising reliability. The FOXBORO FBM227 P0927AC steps in as a robust solution for process control environments facing mixed-signal demands, such as monitoring variable speeds in pumps or actuating valves in real time. This module becomes indispensable in scenarios like upgrading legacy DCS setups or expanding capacity in tight spaces, where you need high-reliability I/O without extensive rewiring. Picture a chemical processing plant dealing with fluctuating pressures and discrete alarms—the FOXBORO FBM227 P0927AC ensures stable signal transmission, preventing data loss that could trigger safety shutdowns or production delays. By focusing on goals like system modularity and signal integrity, it supports engineers in achieving uninterrupted uptime, especially in harsh conditions with electromagnetic noise or temperature swings. For teams managing industrial automation and I/O signal processing, this module shines when integrating diverse field devices into a unified control architecture, reducing the complexity of hybrid analog-digital configurations. It’s particularly vital in distributed systems where quick response to input changes drives output decisions, fostering efficiency without the overhead of multiple specialized modules. The FOXBORO FBM227 P0927AC thus addresses the core need for adaptable, fault-tolerant interfaces that keep your process control robust and scalable.

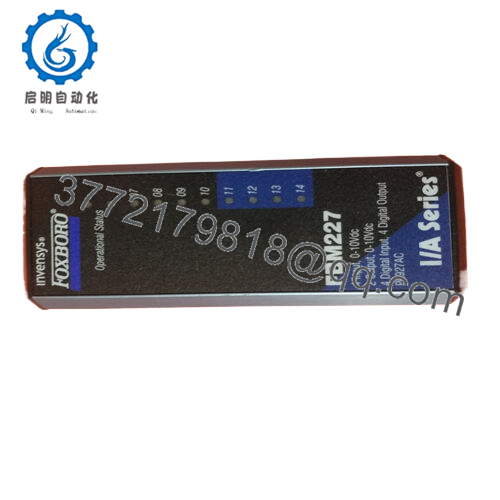

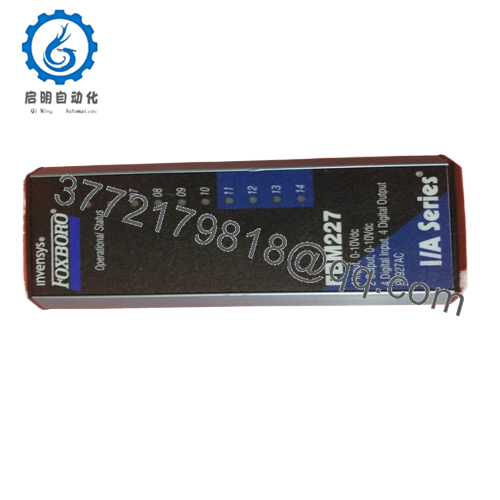

The FOXBORO FBM227 P0927AC operates as a mixed I/O interface module within the Foxboro I/A Series DCS, bridging field devices to the central control platform by conditioning and routing signals across its channels. Positioned in the fieldbus layer of the automation stack, it plugs into a baseplate connected to the system’s backbone, allowing direct interaction with controllers like the FCP270 or network I/O processors. Here, it processes up to four analog inputs—typically 0-10 VDC for precise measurements from sensors—and two corresponding analog outputs for driving actuators, while also managing four digital inputs for status monitoring and four digital outputs for on/off control. This setup enables real-time data exchange via the I/A Series bus, supporting diagnostics like channel health checks and fault logging to flag issues early. In a typical deployment, it complements redundant power supplies and communication modules, ensuring signal isolation to prevent ground loops or noise propagation across the I/O architecture. Protocols like HART can integrate for enhanced device communication if paired with compatible extensions, though the core strength lies in its straightforward analog-digital handling without needing custom programming. For an engineer troubleshooting a loop, it’s like having a smart sentinel: it scales inputs to match output commands seamlessly, fitting into backplane systems where space and reliability are at a premium, and letting you prioritize process optimization over signal wrangling.

| Specification | Details |

|---|---|

| Model Number | FBM227 P0927AC |

| Brand | FOXBORO (Schneider Electric) |

| Type | Mixed Analog/Digital I/O Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Baseplate/DIN Rail |

| Dimensions | 147 mm x 51.5 mm x 114 mm |

| Weight | 0.6 kg |

| Interface/Bus | I/A Series Fieldbus |

| Compliance | CE, RoHS, ISA S71.04 (harsh env.) |

| Supported Protocols | HART (with extensions) |

| Typical Power Draw | 8.5 W |

- FBM227 P0927AC

- FBM227 P0927AC

- FBM227 P0927AC

Opting for the FOXBORO FBM227 P0927AC delivers tangible gains in operational steadiness, as its isolated channels safeguard against common pitfalls like voltage drops or crosstalk, ensuring your process control signals remain accurate even under variable loads. Engineered for endurance in demanding setups, it promotes long-term performance by minimizing signal degradation over time, which cuts down on calibration cycles and keeps your automation running with fewer interventions.

This module’s compact footprint eases integration into crowded cabinets, reducing engineering overhead when retrofitting older systems or scaling for growth—think swapping in without reconfiguring the entire I/O rack. Maintenance efficiency follows suit, with built-in diagnostics that pinpoint issues via status LEDs, allowing quick resolutions that slash downtime in high-stakes environments.

Ultimately, teams see boosted confidence in system responsiveness, as the FOXBORO FBM227 P0927AC handles mixed signals with consistency, translating to smoother workflows and lower total ownership costs in industrial automation.

In power generation facilities, the FOXBORO FBM227 P0927AC deploys in turbine control rooms to manage analog feedback from speed sensors alongside digital interlocks for safety valves, supporting critical system uptime amid rapid load changes and ensuring fast data cycles for grid stability. This setup thrives in continuous operations where even minor signal glitches could cascade into outages.

Chemical processing plants leverage it for batch reactors, where the module processes 0-10 VDC inputs from level transmitters and triggers discrete outputs for agitator starts, excelling in process control environments with corrosive atmospheres and the need for high reliability to maintain product quality.

Water treatment operations integrate the FOXBORO FBM227 P0927AC into filtration skids, monitoring pH analog signals while controlling pump discretes, ideal for harsh, moisture-laden conditions demanding modular I/O for expandable, 24/7 monitoring without compromising signal fidelity.

FBM201 P0916AA – Eight-channel analog input module for expanded voltage monitoring in sensor-heavy applications.

FBM207 P0916JS – Sixteen discrete input variant for high-density status gathering from field switches.

FBM214 P0927AH – HART-enabled eight analog input module for enhanced smart device integration.

FBM219 P0917LE – Twenty-four discrete input/ eight output for large-scale alarm and control needs.

FBM230 P0926GU – Field device system integrator for bridging legacy I/O to modern networks.

FBM232 P0926GW – Ethernet communication module for remote I/O connectivity upgrades.

FBM242 – Discrete output-focused for actuator-heavy setups in drive controls.

FBM04 P0400YE – Legacy 0-20 mA I/O expander for analog output scaling in older I/A Series frames.

Prior to installing the FOXBORO FBM227 P0927AC, confirm compatibility with your I/A Series baseplate and controller firmware to avoid recognition delays—most FBM200 series slots work, but cross-check the revision against the system manual. Assess enclosure airflow, as the module generates moderate heat under full load, and ensure 24 V DC supply stability to prevent startup faults. Grounding is key; verify isolated channels align with your site’s earthing scheme to sidestep noise issues right from the outset.

For maintenance, routine checks involve scanning the front-panel LEDs for channel faults during weekly walkdowns, especially in dusty locales where buildup could affect terminals— a soft cloth wipe suffices quarterly. Annually, during planned outages, run a loop calibration on the analog paths using the DCS diagnostics tool to confirm accuracy, and inspect cable terminations for corrosion. If digital outputs show intermittent behavior, log the event timestamps for pattern analysis, which might reveal upstream power fluctuations. This methodical routine keeps the module humming reliably, with minimal tools needed beyond a multimeter for spot tests.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626