Description

In legacy industrial drive systems, maintaining precise motor control amid varying loads, electrical noise, and demanding duty cycles can be a persistent challenge. Outdated or inconsistent control boards often lead to issues like unstable speed regulation, torque fluctuations, or difficulty integrating with modern diagnostics, especially in applications requiring robust variable speed operation. This becomes particularly critical when extending the life of proven equipment without full system overhauls, where signal reliability and modular upgrades are key to avoiding downtime.

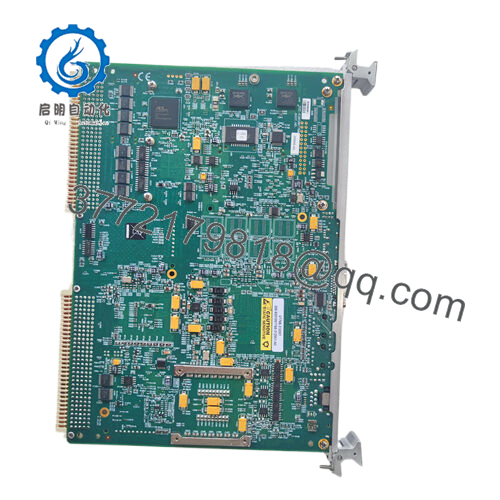

The GE 531X300CCHANM3 addresses these needs directly in industrial automation and process control environments. As a core control board in GE’s DC-300 series of variable speed drives, the GE 531X300CCHANM3 provides essential hardware interfacing for analog signals, ensuring accurate command processing and feedback loops. It’s especially valuable in retrofit scenarios or ongoing maintenance of mature systems, offering high reliability for continuous operation in electrically noisy settings common to manufacturing floors or material handling lines.

The GE 531X300CCHANM3 serves as the primary control assembly board within the DC-300 drive chassis, handling microprocessor-based regulation of armature and field currents for DC motors. It coordinates inputs from operator controls, sensors, and feedback devices, applying closed-loop algorithms to maintain speed and torque precision.

In the broader automation stack, this board sits in the drive’s backplane, interfacing with power bridge modules, I/O terminals, and optional auxiliary cards via edge connectors and headers. It supports basic diagnostic indicators through onboard LEDs and integrates with external monitoring tools for fault logging, though it relies on the drive’s overall architecture rather than advanced fieldbus protocols. Positioned centrally in the control hierarchy, the GE 531X300CCHANM3 enables straightforward parameter adjustments via jumpers or potentiometers, fitting well into modular drive configurations where engineers need dependable analog network handling without complex reprogramming.

- 531X300CCHANM

- 531X300CCHANM

| Specification | Details |

|---|---|

| Model Number | 531X300CCHANM3 |

| Brand | GE (General Electric) |

| Type | Drive Control Board |

| Input Voltage | 5V DC (typical from drive backplane) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Plug-in card (chassis/backplane) |

| Dimensions | Approx. 12 x 9 inches (standard 531X form factor) |

| Weight | Approx. 1.5 kg |

| Interface/Bus | Edge connectors, header pins for auxiliary boards |

| Compliance | UL, CSA (typical for GE industrial drives) |

| Supported Protocols | Proprietary GE drive signaling |

| Typical Power Draw | <15W |

Selecting the GE 531X300CCHANM3 delivers consistent performance in applications where DC motor precision directly impacts productivity. Engineered for long-term performance in industrial settings, it handles electrical transients and thermal stresses reliably, minimizing drift in control loops over years of operation.

This translates to reduced engineering overhead during maintenance, as the board’s standardized design aligns with the DC-300 ecosystem, allowing quick swaps and minimal recalibration. In use, its robust signal conditioning ensures stable operation even with varying input quality, helping teams achieve predictable torque delivery and speed holding without frequent interventions.

The real value emerges in sustained uptime—the GE 531X300CCHANM3 supports the kind of dependable control that keeps processes running smoothly, turning potential weak points in legacy drives into reliable assets for ongoing optimization.

The GE 531X300CCHANM3 is widely deployed in environments demanding critical system uptime and precise motion control. In metals processing, such as steel mills or extrusion lines, it regulates DC motors for rollers and conveyors, managing heavy loads and rapid accelerations in harsh, high-vibration conditions.

Manufacturing facilities, particularly automotive or assembly lines with material handling equipment, rely on it for consistent speed control in continuous operation. Pulp and paper plants also use these boards in winder or conveyor drives, where fast data cycles and resilience to dust or humidity support process control environments requiring 24/7 reliability.

531X300CCHATM3 – Similar base control board with minor revisions for broader compatibility

531X300CCHAHM3 – Variant often used in comparable drive configurations

531X300CCHAFM5 – Enhanced control card for specific spindle applications

531X300CCHAGM5 – Model with integrated keypad support for operator adjustments

531X300CCHACM1 – Earlier generation control board for legacy upgrades

531X300CCHADM2 – Alternative with different auxiliary interfacing

531X300CCHAEM3 – Related board for extended environmental ratings

531X301DCCAFG2 – Higher-level drive control card in the same series

Prior to installing the GE 531X300CCHANM3, confirm backplane slot compatibility and jumper settings match your drive’s configuration—mismatches can affect signal routing. Ensure adequate chassis ventilation, as restricted airflow impacts component longevity, and verify power supply stability to avoid startup issues.

For ongoing maintenance, periodically check onboard LEDs for status and fault indications, which offer quick insights into drive health. Inspect edge connectors for oxidation during planned outages, and perform a basic functional verification of control loops annually to catch any parameter drift early. In systems with auxiliary boards attached, confirm secure mounting to prevent vibration-related issues.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626