Description

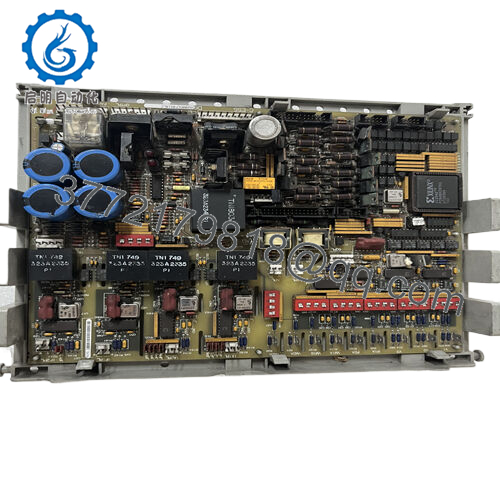

In the pulsing core of heavy-duty gas turbines churning baseload power for grids, where overspeed relays must snap shut in milliseconds to avert catastrophic spins exceeding 3600 RPM, a single contact weld can unleash rotor bursts costing tens of millions in repairs and downtime. Steam plants sequencing emergency trips across boiler feed pumps demand relay boards that isolate high-energy faults from logic cores, preventing false actuations amid arc flashes from 13.8 kV breakers. EX2000 excitation systems in synchronous generators rely on precise relay latching to field flash during startup syncs, dodging pole slips that destabilize entire substations. The GE DS200RTBAG1A confronts these protection imperatives in industrial automation as a relay terminal board for Mark V Speedtronic and EX2000 controls, marshalling dry contacts for trips, interlocks, and annunciations with DPDT reliability. Used in industrial automation for turbine protection and excitation sequencing, it terminates signals from RTBA-compatible processors, applicable in control systems from Frame 9E to hydro governors.

Drilling rigs use the GE DS200RTBAG1A to interface mud pump clutches, dropping loads on high torque without chatter that shears keys. Cement kilns deploy it for flame scanner shutdowns, voting multiple sensors to quench fuel on refractory cracks. Offshore FPSOs lean on its 110 VDC coils for ESD chains, bridging PLC outputs to pneumatic pilots amid saltwater EMI. In these mission-critical loops, the board handles K20-K26 relays rated 10A at 125 VDC, with Berg jumpers configuring NO/NC throws for custom logic. Operators opt for it in upgrades from Mark IV, retaining panel cutouts while boosting contact life to 100K cycles.

Aluminum smelters benefit from the GE DS200RTBAG1A‘s shunt trip feeds to potline busbars, correlating current imbalances to rapid de-energize. Rail traction substations sequence it for pantograph drops, ensuring arc-free disconnects under full load. By hardening relay fabrics in industrial automation, it enforces deterministic response, slashing mean-time-to-trip from seconds to cycles.

Product Introduction & Positioning

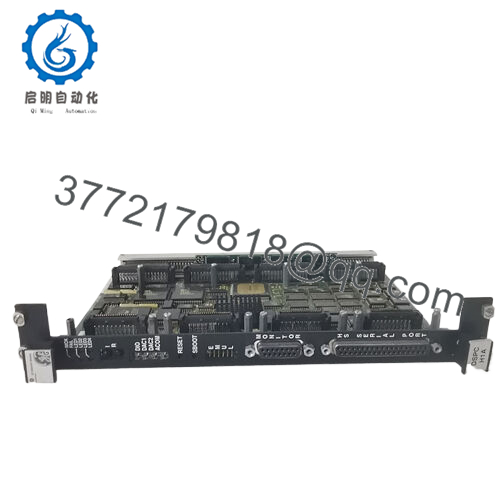

The GE DS200RTBAG1A functions as a robust relay output terminal board in GE’s Mark V turbine management series and EX2000 exciters, providing seven DPDT relays (K20-K26) plus auxiliary contacts for interfacing digital commands from DCC, DCP, or TCP processors to field solenoids and breakers. Featuring stab-in power connectors (CPH/CPN at +125/- VDC), it mounts in <R> or <S> cores via standoffs, driving loads up to 10A continuous with gold-flashed poles minimizing resistance buildup. In turbine enclosures, the GE DS200RTBAG1A isolates 2500 Vrms transients, feeding back coil status to HMIs for closed-loop verification.

Positioned for simplex ops, the GE DS200RTBAG1A pairs with TMR via redundant stabs, supporting seal-in logic for latching trips per NERC PRC-24. Integrators value its plug-compatible headers to DSPC or DSPX cards, enabling field retrofits without harness rewires. Its edge? Configurable jumpers tailor coil suppression for inductive kicks, while test points expose armature voltages sans disassembly.

For protection engineers, the GE DS200RTBAG1A embeds in EX2100 cabinets, scaling to 115 VAC variants for global sites. Native tie-ins to ToolboxST diagnostics position Mark V as enduring backbone for gigawatt fleets demanding zero-false-trip integrity.

Key Technical Features & Functional Benefits

Control room crews depend on the GE DS200RTBAG1A‘s bifurcated contacts—dual poles per throw ensure make-before-break on transfers, vital for permissive chains where single failures orphan sequences. 125 VDC coils pull 50 mA inrush, latching with <5 ms dropout to outpace overspeed governors. Diode suppression across each squelches 1000V spikes from solenoids, extending upstream FPGA life.

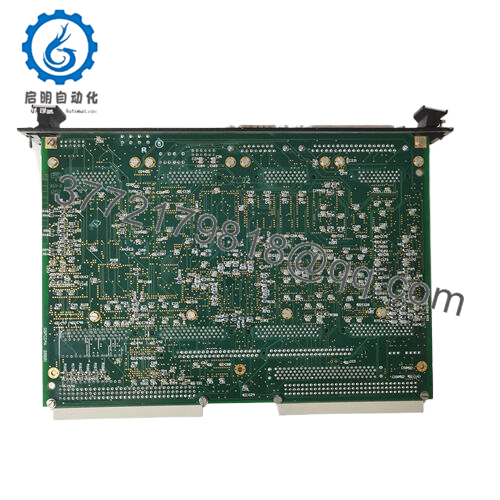

Board spans 10×6 inches in VME racks, passive-cooled at 8W dissipation—ideal for tropical enclosures sans fans. Eurostyle barriers accept 14 AWG stranded, torqued 10 in-lbs for seismic hold-down to 5g. Aux contacts mirror states to %Q bits, enabling trend capture of chatter events for RCA.

Proven in 30-year deployments, FR4 epoxy with solder-mask repels oils and 95% RH, logging MTBF >500K hours. Self-wipe silver alloy poles resist pitting from DC arcs, with dropout indicators flagging stuck relays via continuity checks. Field-modifiable via Berg pins for NC defaults, it adapts to site-specific trip matrices without respins.

- DS200RTBAG1A

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE DS200RTBAG1A |

| Brand | GE (Emerson) |

| Type | Relay Terminal Board (RTBA) |

| Power Supply | 115-125 VDC (CPH/CPN stabs) |

| Operating Temperature | -30°C to +65°C |

| Mounting | VME rack standoffs |

| Dimensions | 260 x 150 x 25 mm (L x W x H) |

| Weight | 0.65 kg |

| Interfaces | 7x DPDT relays, aux contacts |

| Certifications | UL, CSA Class I Div 2 |

| Cooling | Natural convection |

| Environmental Rating | IP20, 5-95% RH |

Related Modules or Compatible Units

DS200DCPAG1A – Processor card driving GE DS200RTBAG1A relay commands in Mark V cores.

DS200DSPCH1A – DSP controller interfacing directly to GE DS200RTBAG1A for EX2000.

DS200RTBAG2A – 24 VDC variant for low-voltage ties with GE DS200RTBAG1A systems.

DS200TBCAG1A – Analog termination complementing GE DS200RTBAG1A in <C> stacks.

DS200KLDBG1A – Keypad/display panel monitoring GE DS200RTBAG1A statuses.

EXC2000 – Exciter frame housing GE DS200RTBAG1A for generator field control.

DS200TCQAG1A – Overspeed terminal linking trips through GE DS200RTBAG1A.

Installation Notes & Maintenance Best Practices

Install the GE DS200RTBAG1A in <R> slot 5-9, aligning stabs to motherboard before latching—cycle power to verify no shorts via ohm-out to ground. Crimp 16 AWG with boots to TB1-7, observing polarity on suppressed coils (cathode to +); torque 9 in-lbs max per GEH-5000. Jumper JP1-3 for enable masks if TMR; segregate trip wiring in dedicated trays from speed signals. Bench-test contacts with 1kΩ loads pre-ship, logging initial resistances <50 mΩ.

Every 2000 hours, toggle relays via HMI forcing—multimeter dropouts to flag welds (>0.2V). Semiannually, extract for visual arc pitting, burnishing poles with 600 grit if oxidized. Annual coil resistance logs (250-300Ω nominal) predict failures; swap preemptively at 80K cycles. Purge enclosure post-flooding, drying at 50°C before recommission.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626