Description

In industrial drive systems for turbines, exciters, and large motors, achieving precise regulation of speed, torque, current loops, and protection functions requires a robust central processor capable of handling multiple I/O types, real-time math-intensive calculations, and system-wide diagnostics without introducing latency or instability. Challenges intensify in high-power applications where mismatched processing, software incompatibilities, or insufficient noise immunity can lead to erratic control, inefficient energy use, or protective trips that halt production. In AC/DC drive configurations or turbine auxiliaries demanding seamless integration with LAN communications and auxiliary cards, a dedicated primary controller becomes essential for deterministic performance and long-term reliability in demanding process control environments.

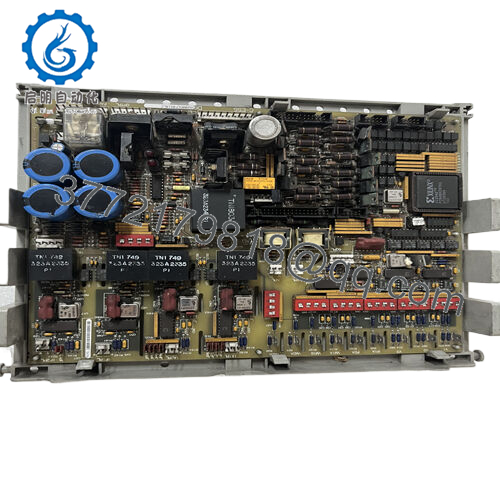

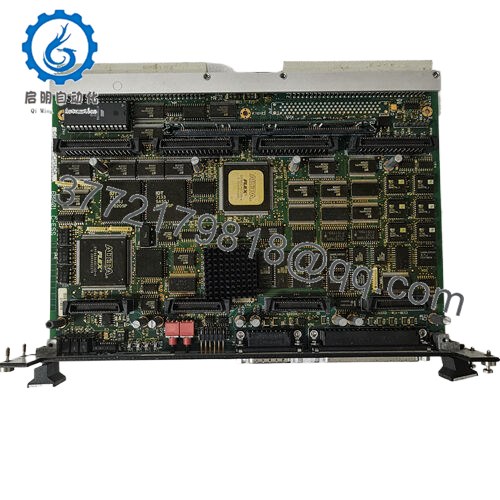

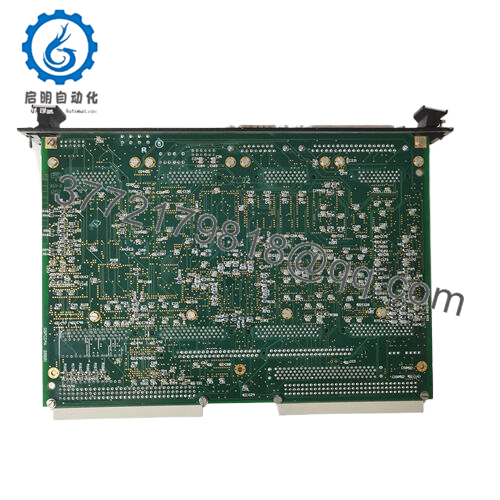

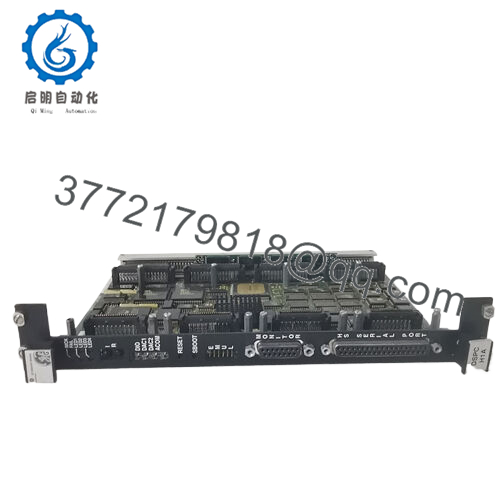

The GE DS200SDCCG1AFD addresses these demands as the primary Drive Control Card in the Speedtronic Mark V series, delivering high-reliability processing for industrial automation and turbine control systems. It incorporates three 16-bit microprocessors with shared RAM to distribute tasks efficiently—one for core drive control, another for motor-specific algorithms, and a third for I/O handling—ensuring responsive regulation even under varying loads. This card proves critical in situations requiring comprehensive diagnostics, configurable I/O signal management, and support for technology-specific functions like phase control or motion algorithms, where any processing bottleneck risks reduced efficiency or safety issues. By providing built-in watchdog timers, LED status monitoring, and jumper-configurable options, the GE DS200SDCCG1AFD enhances signal reliability and system stability in process control setups, particularly when sustaining legacy Mark V installations or interfacing with diverse drive types.

The GE DS200SDCCG1AFD serves as the central processing unit in the Mark V drive control stack, typically installed in the main rack and interfacing with auxiliary cards via multiple connectors for signal exchange. It processes analog and digital I/O, executes inner-loop regulators (e.g., current, speed), and runs application-specific software loaded via serial or LAN ports. Positioned at the heart of the control hierarchy, it communicates with LAN cards (like SLCC), power supply boards (DCFB), and I/O terminals over ribbon cables or backplane, ensuring low-latency coordination.

The card supports onboard operator interface for diagnostics and configuration, with one microprocessor dedicated to high-speed peripherals and timers. It integrates seamlessly into broader Mark V architectures, often alongside co-processors for math-heavy tasks, while relaying faults to the HMI. Software adjustments allow tailoring to AC2000, DC2000, or similar drives without custom hardware. The GE DS200SDCCG1AFD prioritizes deterministic execution, making it suitable for real-time control where precise timing prevents overshoots or instability.

- DS200SDCCG1AFD

| Specification | Details |

|---|---|

| Model Number | DS200SDCCG1AFD |

| Brand | GE (Speedtronic Mark V) |

| Type | Drive Control Card (Primary Controller) |

| Input Voltage | 5V DC / ±15V DC (backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | VME-style rack slot |

| Dimensions | Standard Mark V card (approx. 12 x 9 inches) |

| Weight | Approx. 2 kg |

| Interface/Bus | Multiple ribbon connectors, backplane |

| Compliance | CE, UL (industrial standards) |

| Supported Protocols | Mark V internal drive signaling |

| Typical Power Draw | <50W |

Deploying the GE DS200SDCCG1AFD equips your system with a controller engineered for resilient multitasking in drive regulation loops, where shared RAM and dedicated processors ensure long-term stability amid electrical noise and thermal variations. Its comprehensive I/O handling and built-in functions deliver consistent performance across diverse drive technologies.

Integration benefits are notable in legacy systems—modular connectors and software configurability reduce engineering overhead, allowing straightforward adaptations or expansions. In practice, the value emerges through maintenance efficiency: ten LEDs and test points enable rapid status checks and signal probing, while diagnostic relays support predictive interventions.

At its core, the GE DS200SDCCG1AFD reinforces process control reliability by providing a fault-tolerant processing foundation that optimizes energy use, protects equipment, and sustains high-availability operations in critical industrial automation setups.

The GE DS200SDCCG1AFD is frequently used in power generation plants with gas or steam turbines, where it manages auxiliary drives or exciters requiring precise current regulation under harsh conditions of vibration and heat. In oil and gas compressor stations, it controls large motor drives for continuous uptime during variable demands.

Manufacturing facilities with heavy process drives—such as pumps, fans, or conveyors—deploy it for torque and speed control, handling fast data cycles while tolerating transients. These process control environments rely on its multi-processor architecture for critical system uptime in high-power applications.

DS200SDCCG1AGD – Later revision with potential enhancements in diagnostics or compatibility

DS200SDCCG1AHD – Updated group variant for specific drive configurations

DS200SDCCG1ABA – Earlier functional revision for baseline applications

DS200SLCCG1AFG – LAN communication card frequently paired for network integration

DS200DCFBG1B – Power supply board commonly used in the same rack

DS200FCRRG1AKD – Firing circuit board for bridge control interfacing

DS200LDCCH1A – Drive/LAN control alternative for expanded communications

DS200SDCCG4AGD – Higher group version for advanced drive types

Before installing the GE DS200SDCCG1AFD, confirm rack slot and backplane compatibility—verify jumper positions match your drive type and software revision to avoid signal conflicts. Ensure ribbon cables are undamaged and properly routed away from heat sources, with secure seating to maintain noise immunity.

Maintenance typically includes regular LED monitoring for processor status and faults, plus connector inspections for tightness in vibrating cabinets. Use test points for periodic signal verification during outages, and archive configuration files for quick reloads. A biennial software validation—checking inner loops and watchdog response—helps confirm ongoing reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626