Description

What This Product Solves

In high-stakes industrial automation environments, the single biggest risk to continuous production is often an unplanned drive system outage. When a coordinated drive system loses its ability to process speed feedback, handle synchronization signals, or communicate reliably with the controller, the result is immediate trip events, lost production, and expensive emergency repairs. The GE DS215DMCBG1AZZ was created specifically to eliminate that vulnerability inside GE Speedtronic Mark V turbine control systems and large DC/AC drive installations.

This board is the complete drive motor control and genius interface card for Innovation Series and DC-2000/DC-3000 systems that still form the backbone of power generation, oil & gas compression, and heavy-process plants worldwide. It solves the problem of fragile or obsolete drive control electronics by combining high-speed microprocessor control, isolated I/O signal conditioning, and direct LAN communication in one rugged, field-proven module. Engineers turn to the GE DS215DMCBG1AZZ when they need absolute confidence that tachometer feedback, flux vector calculations, and armature/bridge control loops will remain stable 24/7—even in hot, electrically noisy turbine enclosures or steel-mill environments where lesser boards fail within months.

Whether you’re dealing with a cracked trace on an original DMCB, intermittent genius bus dropouts, or simply planning a strategic spare strategy, dropping in the GE DS215DMCBG1AZZ restores full system integrity without forcing a complete panel redesign or costly drive retrofit.

How the Product Works & Fits into a System

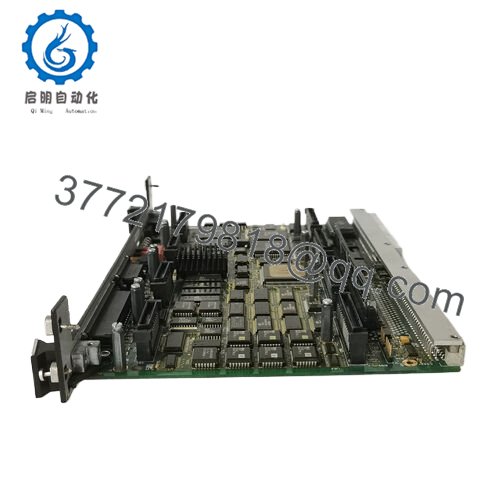

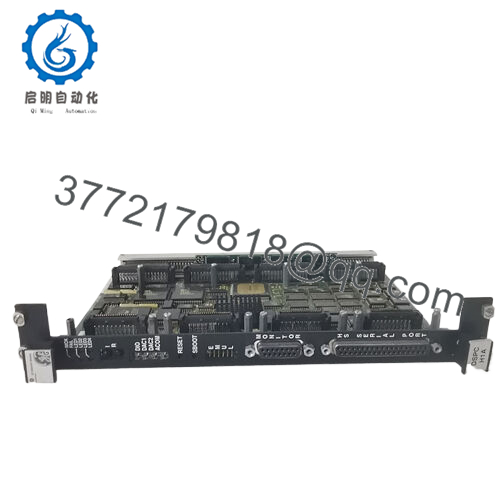

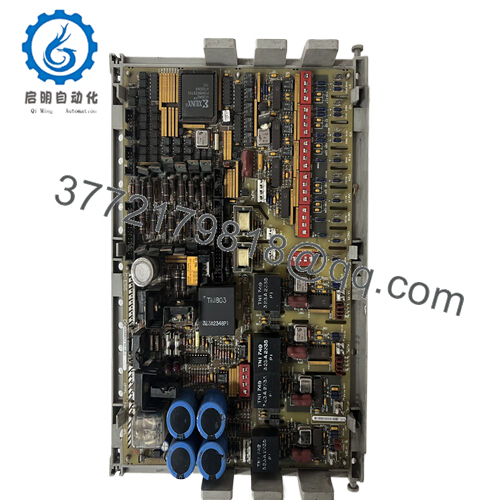

The GE DS215DMCBG1AZZ sits at the heart of the drive control architecture in Mark V and Innovation Series racks. It plugs directly into the VME-based backplane alongside the UCVE or UC2000 controller and communicates over the high-speed Genius I/O LAN as well as the internal drive bus. The board handles all real-time motor control tasks: processing up to three channels of encoder or resolver feedback, executing inner current and outer speed loops at microsecond rates, and managing bridge firing for thyristor or IGBT power stages.

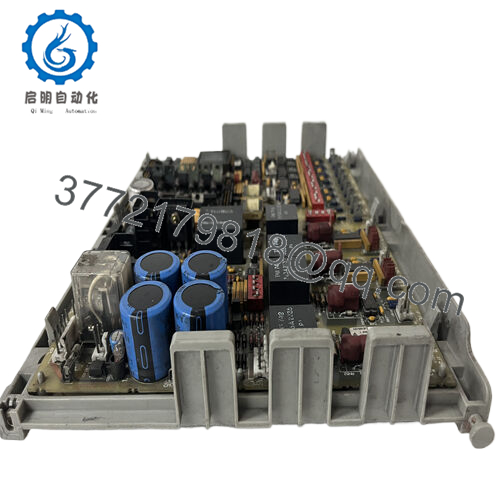

It provides fully isolated analog and digital I/O for field signals—tach feedback, current transformers, contactor status, and emergency stop chains—while maintaining galvanic separation that protects the control rack from ground loops and transients. On-board diagnostics continuously monitor phase loss, over-temperature, communication health, and processor sanity, reporting everything through the Genius network to the HMI or historian. Because the GE DS215DMCBG1AZZ is software-compatible with the older DS215DMCBG1AZZ01A and DS215DMCBG1AZZ03A versions, migration is typically just a matter of swapping the card and verifying configuration with Toolbox or CIMPLICITY—no code changes required.

Technical Highlights Summary

| Specification | Details |

|---|---|

| Model Number | DS215DMCBG1AZZ |

| Brand | GE (General Electric) |

| Type | Drive Motor Control & Genius Interface Board |

| Input Voltage | 24 VDC (from rack power supply) |

| Operating Temp Range | 0°C to 60°C (convection cooled) |

| Mounting Style | VME rack, double Eurocard slot |

| Dimensions | 362 mm × 265 mm × 35 mm (standard 6U height) |

| Weight | 1.8 kg |

| Interface/Bus | VME, Genius I/O LAN, Drive-specific serial |

| Compliance | CE, UL (panel), Class I Div 2 capable |

| Supported Protocols | Genius I/O, Mark V IONet, proprietary drive |

| Typical Power Draw | 28 W nominal, 45 W max |

Real-World Benefits

Choosing the GE DS215DMCBG1AZZ means you’re no longer gambling on 25-year-old drive control boards that are impossible to repair at the component level. The card is engineered for long-term performance in turbine and large-drive applications, with conformal-coated circuitry and extended-temperature components that shrug off the heat cycles and vibration common in generator skids and compressor stations. Plants routinely see MTBF figures well beyond 15 years when these boards are part of a proper spares program.

Maintenance teams appreciate the built-in LED matrix and Genius diagnostics that turn what used to be hours of oscilloscope tracing into a five-minute status check. Because the board retains full backward compatibility, you avoid the massive engineering overhead of re-validating control algorithms or rewiring field terminals—simply restore the rack to its original certified state. That translates directly into shorter outages and lower risk during scheduled turbine overhauls or emergency call-outs.

Typical Use Cases

The GE DS215DMCBG1AZZ is most commonly found controlling 5–50 MW gas turbines in combined-cycle power plants, where it manages generator excitation coordination and load-sharing across multiple units. In pipeline compression stations, it runs large DC or AC pipeline motors that demand rock-solid speed regulation under widely varying gas pressures. Steel and paper mills also rely on it for reversing mill stands and winder applications that require precise torque control and instantaneous fault response to protect mechanical equipment.

These are environments where critical system uptime is measured in seconds, not hours, and where electrical noise, high ambient temperatures, and continuous 100% duty cycles are the norm. The GE DS215DMCBG1AZZ delivers the reliability needed to keep these processes running without unplanned trips.

Compatible or Alternative Products

DS215DMCBG1AZZ03A – Factory-new equivalent with latest firmware revision

DS215DMCBG1AZZ01A – Earlier revision, functionally identical for most applications

DS200DMCBG1A – Mark V predecessor board (requires minor jumper changes)

DS215SLCCG1AZZ01A – Companion LAN communication card often paired in same rack

DS215SDCCG1AZZ01B – Combined drive control and secondary processor board for redundant setups

DS200SLCCG1A – Older LAN interface if Genius network needs expansion

IS220PDIAH1A – Modern Mark VIe discrete input pack (migration path for full system upgrade)

IS220YDIAS1A – Mark VIe discrete contact input alternative for newer retrofits

- DS215DMCBG1AZZ

- DS215DMCBG1AZZ

Setup Notes & Maintenance Insights

Before installation, confirm your rack has the correct 24 VDC power supply rating (at least 10 A total capacity) and that adjacent slots have adequate airflow—leave one empty slot on each side if you’re running near 60°C ambient. Verify the Genius I/O termination resistor settings and node address using the rotary switches on the front edge; mismatch is the most common cause of communication alarms after a swap.

Firmware is field-loadable via the UCVE controller, so always check you’re running the version recommended in GE TIL 1678 or later. Once installed, the on-board LEDs give you immediate health status—steady green heartbeat means the processor is happy. Every major outage, spend ten minutes cycling through the diagnostic screens in Toolbox to baseline the fault counters. Annual maintenance is straightforward: visual inspection of the edge connector for oxidation, gentle cleaning with approved contact cleaner if the site is coastal, and a quick Genius bus health check. Keep one spare on the shelf rotated every five years and you’ll never be down waiting for a board.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626