Description

In legacy gas and steam turbine control systems, scaling up functionality without major redesigns often creates bottlenecks—limited auxiliary I/O, constrained signal processing for custom logic, or difficulty incorporating specialized functions like additional sequencing or monitoring points. This becomes critical in mature installations where the core controller handles primary regulation but lacks capacity for evolving operational needs, risking reduced flexibility or forced downtime during upgrades.

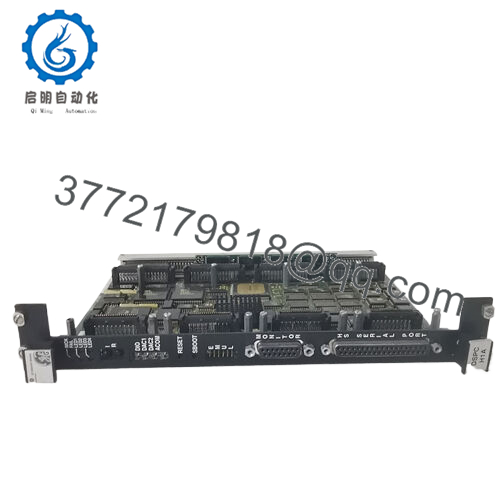

The GE DS3800DFXD1B1D provides a targeted solution in industrial automation and process control, particularly for GE Speedtronic Mark IV turbine management systems. As an auxiliary function expander board, the GE DS3800DFXD1B1D extends the core control rack’s capabilities by adding extra logic processing, I/O interfacing, and custom function support, ensuring high reliability in demanding turbine environments. It’s especially essential when expanding control sequences, integrating new sensors, or adapting to changing regulatory requirements without replacing the entire panel.

The GE DS3800DFXD1B1D integrates directly into the Mark IV rack as a daughterboard or auxiliary card, typically mounting via pogo pins or edge connectors to the primary control boards. It expands available functions by handling additional discrete inputs/outputs, timing circuits, or intermediate signal conditioning that the main processor offloads.

Within the broader automation stack, this expander sits in the I/O and control layer, interfacing with core cards like the microprocessor controller or regulator boards over the rack’s parallel bus. It supports diagnostic feedback through status indicators and aligns with Mark IV’s triple-redundant architecture for fault-tolerant operation. The GE DS3800DFXD1B1D enables engineers to implement extended algorithms—such as custom interlocks or alarm routing—while maintaining compatibility with existing wiring and programming tools, fitting modular expansions in turbine control cubicles.

- DS3800DFXD1B1D

- DS3800DFXD1B1D

| Specification | Details |

|---|---|

| Model Number | DS3800DFXD1B1D |

| Brand | GE (General Electric) |

| Type | Auxiliary Function Expander Board |

| Input Voltage | 5V DC (from rack backplane) |

| Operating Temp Range | -30°C to +65°C (typical for DS3800 series) |

| Mounting Style | Rack-mounted auxiliary (pogo pin or edge connector) |

| Dimensions | Approx. 8.5 x 11 inches (standard DS3800 form factor) |

| Weight | Approx. 1 kg |

| Interface/Bus | Parallel rack bus, auxiliary connectors |

| Compliance | UL, CSA (typical for Mark IV components) |

| Supported Protocols | Proprietary GE Speedtronic signaling |

| Typical Power Draw | <10W |

Selecting the GE DS3800DFXD1B1D brings measurable stability to expanded turbine control setups. Engineered for long-term performance in vibration-prone and thermally variable conditions, it maintains signal integrity across added functions, preventing drift or interference that could affect primary regulation.

This consistency reduces engineering overhead during system growth, as the board’s plug-in design and standardized interfacing minimize custom coding or rewiring. In practice, it ensures seamless addition of monitoring points or logic paths, supporting sustained high reliability without compromising core safety loops.

The true advantage shows in operational resilience—the GE DS3800DFXD1B1D empowers teams to evolve control strategies proactively, delivering the flexibility needed for optimized turbine efficiency and extended asset life.

The GE DS3800DFXD1B1D is frequently deployed in environments demanding critical system uptime and adaptable control logic. In combined-cycle power plants, it expands sequencing for fuel transfer or load sharing, handling harsh conditions like elevated temperatures and electrical noise during continuous generation.

Gas turbine peaking facilities use it for rapid-start enhancements, supporting fast data cycles in startup/shutdown routines. Oil and gas compressor stations also incorporate the GE DS3800DFXD1B1D in process control environments, where additional auxiliary functions ensure reliable operation amid remote or explosive atmospheres.

DS3800DFXD1B1B – Minor revision variant with similar expansion capabilities

DS3800DFXB1B1C – Related expander for alternate I/O configurations

DS3800DFXA1B1C – Variant supporting specialized pulse or frequency functions

DS3800HMPK1E1D – Microprocessor board often paired as primary host

DS3800NPSE1E1E – Power supply module for rack support in expanded setups

DS3800HCVA1C1C – Digital-to-analog converter companion for signal extension

DS3800HRDA1B1A – Relay driver board for additional output control

DS3800HAIA1E1D – Analog interface card commonly used in tandem

Before adding the GE DS3800DFXD1B1D, check rack slot availability and connector alignment—ensure the primary board supports the pogo pin or edge interface to avoid signal issues. Confirm power budget within the rack supply, as added draw can affect stability, and review firmware compatibility for full function recognition.

Maintenance is primarily visual and preventive: inspect mounting security and connector cleanliness during routine panel checks, watching for dust buildup in high-particulate settings. Front indicators (if present) offer quick status verification, and a periodic rack reseat during outages helps mitigate contact oxidation. In redundant Mark IV cores, test expander failover paths annually to validate seamless operation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626