Description

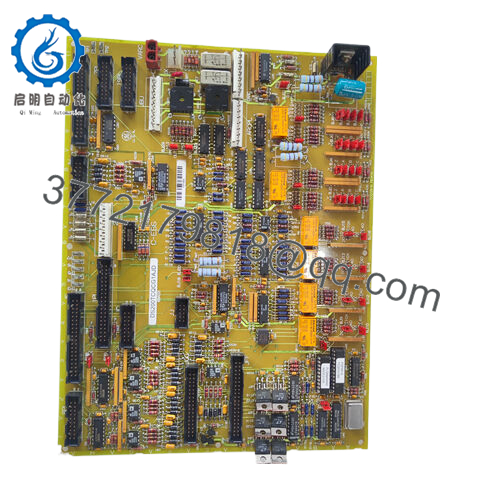

In the high-stakes exciters of synchronous generators driving megawatt grids, where field currents must ramp flawlessly from zero to 5000 A during synchronization without voltage dips that destabilize loads, a control glitch risks pole slips tearing rotors apart. Pulp mills powering refiner motors through brushless exciters demand precise thyristor firing to hold 95% power factor amid pulp density swings, averting harmonic trips that stall beaters. Steel rolling stands fed by static exciters need instantaneous ceiling currents to punch through strip breaks, preventing mill stands from seizing under torque overloads. The GE DS3800DMEC1D1D confronts these excitation challenges in industrial automation as a motor exciter control board from GE’s Mark IV Speedtronic series, orchestrating gate pulses and feedback loops for SCR bridges in MD/MX exciters. Used in industrial automation for generator field regulation and AVR functions, it mounts in turbine control cabinets, applicable in control systems from hydro units to fossil-fired primes.

Marine propulsion diesels equip the GE DS3800DMEC1D1D for shaft generators, tracking rotor angles to inject precise DC amid propeller torque pulses. Cement ball mills leverage it for wound-rotor drives, scaling field weakening to hit grind fineness without slip rings arcing. Offshore platforms use its regulator loops for emergency diesel sets, ensuring blackout-free black starts in 10 seconds. In these power-dense environments, the board drives 7 terminal blocks for interlocks and CT inputs, with 14 trimpots fine-tuning PID gains and limits. Operators favor it for retrofits into legacy exciters, preserving panel footprints while adding soft-start ramps that cut inrush by 30%.

Hydro pump-storage reversals benefit from the GE DS3800DMEC1D1D‘s demagnetizing sequences, smoothly flipping fields without overshoots that stress windings. By embedding stable excitation into industrial automation cores, it boosts synchronizing windows from 5° to 15°, lifting plant dispatchability in volatile grids.

Product Introduction & Positioning

The GE DS3800DMEC1D1D is a core control board in GE’s Mark IV exciter lineup for MD static exciters, generating firing pulses for thyristor bridges via 20 jumpers and a 20-pin ribbon cable linking to power sections. Featuring 2 status LEDs and 7 connector terminals for field CTs, armature voltage, and PSS signals, it processes regulator demands from <Q> core processors to output ±10 V analogs scaled to ceiling/demag limits. Rack-mounted in <C> stacks, the GE DS3800DMEC1D1D employs opto-isolated gates pulsing at line frequency, supporting droop, isochronous, and PF modes per IEEE 421.5.

Positioned for 50/60 Hz grids up to 100 MVA, the GE DS3800DMEC1D1D interfaces via backplane bus, with trimpots adjusting UEL/OEL setpoints and tracking gains for bump-less transfers. Integrators value its plug-in compatibility with DMC/DSTC cards, easing swaps in flooded compartments. In Mark IV architecture, it sits upstream of bridge amplifiers, isolating 2500 V spikes to safeguard microprocessors.

For OEMs, the GE DS3800DMEC1D1D adapts via jumpers to brushless PMG feeds, positioning legacy exciters for life extensions amid utility DLNs. EEPROM-stored calibrations enable field tweaks without eproms, streamlining commissioning worldwide.

Key Technical Features & Functional Benefits

Field engineers tune the GE DS3800DMEC1D1D‘s 14 pots for zero-cross firing, achieving 0.1% voltage regulation across ±20% speed swings—critical for islanded blackstarts. Isolated gate drivers pulse 30 mA peaks to SCRs up to 1000 A ratings, with phase-lock loops syncing to sensed rotor slip <0.5 Hz. Dual LEDs flag healthy firing or fault latchouts, speeding diagnostics in smoke-filled enclosures.

Compact PCB fits <PD> slots drawing <3W from +5/-15V rails, convection-cooled for 55°C ambients. Ribbon cable spans 1m to remote bridges without signal sag, while terminals handle 14-22 AWG for CT burdens to 0.5 VA. Jumpers select min/max field amps, tailoring to salient pole or cylindrical rotors.

Rugged silkscreened FR4 with solder-mask shrugs 95% RH and vibration to 2g, logging MTBF >200K hours. Self-test on power-up verifies pulse symmetry, blocking de-excites on asymmetry >5%. Trimpot locks prevent drift, with voltage dividers scaling 600 Vac to 10 Vdc for AVR feedback.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE DS3800DMEC1D1D |

| Brand | GE |

| Type | Exciter Control Board |

| Power Supply | +5 VDC, ±15 VDC |

| Operating Temperature | 0°C to 55°C |

| Mounting | Mark IV <C> rack |

| Dimensions | 280 x 140 x 15 mm (L x W x H) |

| Weight | 0.28 kg |

| Interfaces | 7x terminals, 20-pin ribbon, jumpers |

| Certifications | UL, CSA |

| Cooling | Natural convection |

| Environmental Rating | IP20, 5-95% RH |

- DS3800DMEC1D1D

- DS3800DMEC1D1D

Related Modules or Compatible Units

DS3800DMEA – Exciter amplifier driven by GE DS3800DMEC1D1D pulses.

DS3800NHVM – High-voltage monitor feeding GE DS3800DMEC1D1D limits.

DS3800DPMP – Power module paired with GE DS3800DMEC1D1D in MD sets.

DS3800DSTC – Signal conditioner sourcing GE DS3800DMEC1D1D feedbacks.

DS3800NFBE – Field bridge extension for GE DS3800DMEC1D1D gates.

DMC – Digital core processor commanding GE DS3800DMEC1D1D regs.

DS3800HPDM – Demag module triggered by GE DS3800DMEC1D1D.

Installation Notes & Maintenance Best Practices

Slot the GE DS3800DMEC1D1D into <C> position 6-9, seating ribbon firmly before powering—verify LED sequence per GEH-4040. Ferrule CT leads to J1 polarity (+ to H1), torque 7 in-lbs; jumper W1-W20 for 60 Hz sync. Cal pots with decade box: VR1 field gain to 5V/1000A, VR5 UEL to 105%. Ground chassis stud <1 ohm, routing gates away from HV bus.

Monthly, log LED states post-ramp; tweak VR10 tracking if overshoot >2%. Quarterly, inject 1A CT sim, checking pulse trains on scope (>95% duty symmetry). Annual pot audits with digital voltmeter reset drifts >1%; reseal with RTV if flux creeps. Offline bench-test gates with dummy SCRs pre-outage.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626