Description

In many legacy industrial automation setups, particularly those relying on GE Speedtronic Mark IV turbine control systems, engineers frequently encounter challenges when maintaining or extending the life of aging control hardware. These systems, deployed since the 1980s in critical power generation applications, demand high reliability for real-time processing of sensor data, execution of control algorithms, and coordination across distributed I/O. Over time, component degradation, obsolescence, or the need for precise signal multiplexing can lead to intermittent faults, reduced processing speed, or outright failures that threaten turbine stability and force unplanned outages.

This becomes especially critical in environments where multiple analog and digital signals must be routed efficiently to a central processor without introducing latency or errors. In process control for gas turbines, any delay in data handling or computation can compromise protective functions like overspeed trips or flame detection, directly impacting safety and availability.

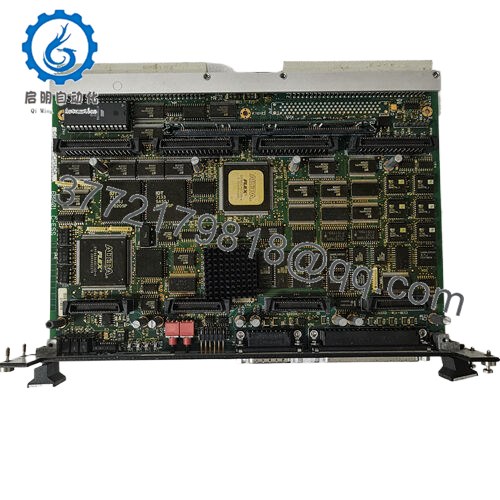

The GE DS3800HMPK1K1K addresses these needs as a dedicated microprocessor board engineered for the Mark IV architecture. It provides the core computing power and signal multiplexing capabilities required to manage high-density I/O signals reliably. Common scenarios include life extension projects on Frame 5, 6, or 7 turbines, where replacing a failed processor restores full functionality without migrating to newer platforms. In industrial automation settings with continuous operation demands, the GE DS3800HMPK1K1K ensures deterministic execution of control logic, supporting seamless integration of field signals while maintaining the system’s triple-redundant voting structure for fault tolerance. By handling data streams from thermocouples, vibration sensors, and servo valves with precision, it helps prevent cascading issues that could arise from unreliable processing in harsh, high-vibration environments.

The GE DS3800HMPK1K1K functions as the primary microprocessor within specific Mark IV control panels, often mounted in the core rack alongside I/O and communication cards. In the Speedtronic Mark IV stack, it sits at the heart of the distributed processing layer, executing firmware stored in EPROM modules to perform real-time calculations for turbine sequencing, fuel control, and protection.

It connects via dual 50-pin ribbon cables for parallel data exchange and a 34-pin interface for additional signaling, allowing it to interface directly with auxiliary cards like analog input terminators or relay drivers. The board supports the Mark IV’s proprietary bus architecture, enabling coordinated operation across redundant processors for voting on critical decisions. Basic onboard diagnostics come through visible LEDs—three red for fault indications and one amber for power-up self-test completion—providing quick visual confirmation of health without external tools.

When integrated, the GE DS3800HMPK1K1K processes multiplexed inputs efficiently, routing multiple channels to the CPU while preserving signal integrity in noisy turbine skids. This positioning in the automation hierarchy makes it indispensable for brownfield sites aiming to retain proven Mark IV reliability rather than undertake full retrofits.

- DS3800HMPK1K1K

| Specification | Details |

|---|---|

| Model Number | DS3800HMPK1K1K |

| Brand | General Electric (GE) |

| Type | Microprocessor Board |

| Input Voltage | +5 V DC |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | Rack-mounted with retention levers |

| Dimensions | Approx. 33.0 cm x 17.8 cm |

| Weight | Approx. 1 kg |

| Interface/Bus | Mark IV Speedtronic (ribbon connectors) |

| Compliance | Legacy industrial standards (UL recognized components) |

| Supported Protocols | Proprietary Mark IV |

| Typical Power Draw | Low (microprocessor class, <20 W estimated) |

Selecting the GE DS3800HMPK1K1K delivers proven computational reliability that directly supports extended turbine life in demanding applications. Engineered for the rigors of continuous duty, it maintains consistent cycle times for control loops, ensuring protective functions respond predictably even under load variations or transient events.

In operation, the onboard multiplexing reduces engineering overhead by consolidating signal paths, minimizing wiring complexity and potential points of failure compared to discrete solutions. Long-term performance benefits from robust construction, with heat management designed around natural convection and careful cable routing to sustain microprocessor integrity over decades.

For maintenance teams, the board’s diagnostic LEDs and modular design contribute to efficiency—quick swaps restore redundancy without extensive recalibration. When deployed in redundant configurations, the GE DS3800HMPK1K1K enhances overall system availability, allowing seamless failover and reducing the risk of forced derates. This translates to tangible value in process control environments where uptime directly affects generation revenue and operational costs.

The GE DS3800HMPK1K1K is widely deployed in gas turbine installations requiring unwavering control precision under harsh conditions. In power plants operating heavy-duty frames, it’s essential for managing startup sequences, load control, and shutdown protection, where fast data cycles and critical system uptime prevent trips that could cost hours of production.

Oil and gas facilities use it in compressor stations or pipeline turbines, handling vibration monitoring and valve positioning in environments with extreme temperatures and electrical noise. Combined-cycle plants rely on its multiplexing for integrating steam and gas turbine data streams, supporting efficient heat recovery and overall plant optimization.

These industrial automation applications highlight the board’s strength in sustaining reliable processing for protective relaying and sequencing in setups demanding 99.99% availability.

DS3800HMPK1J1J – Variant with updated EPROM configuration for specific firmware revisions

DS3800HMPK1L1K – Alternative suffix for enhanced diagnostic features

DS3800HMPK1M1K – Similar microprocessor with minor component revisions

DS3800HMPK1N1K – Higher-spec version often used in regulator applications

DS3800DMPK1E1D – Daughterboard commonly paired for expanded processing

DS3800HMPF – Related CPU card in the same family

DS3800HPBC – Parallel bus communication card for inter-panel linking

Prior to installing the GE DS3800HMPK1K1K, confirm rack slot compatibility and verify that ribbon cables are undamaged—inspect for bent pins or fraying that could disrupt data transfer. Check jumper settings against your system’s configuration drawings, as these dictate operational modes, and ensure adjacent slots allow sufficient airflow around the microprocessor to prevent thermal buildup.

Power supply stability is key; validate +5 V rails are within tolerance before insertion. During ongoing maintenance, focus on periodic visual inspections: monitor LED patterns during operation for early fault detection, and clean dust accumulation that might impede cooling. Ribbon connectors benefit from occasional reseating to maintain contact integrity, especially in high-vibration settings.

Self-tests run on power-up, so observe the amber LED sequence during restarts. With proper handling—always using static protection—these boards typically require minimal intervention beyond routine panel checks, aligning well with predictive strategies that emphasize condition monitoring over scheduled overhauls.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626