Description

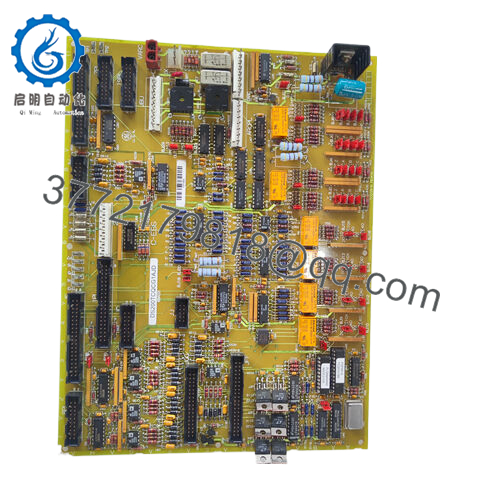

The GE DS3800HPTL1F1D is a GE Speedtronic Mark IV turbine control board typically used in heavy-duty gas and steam turbine applications where long-term availability of spares and stable control behavior matter more than constant platform upgrades. In real plants, boards from the DS3800HPTx family are commonly associated with interfacing, protection, or drive/gate functions related to turbine auxiliaries, excitation, or power electronics, so you will often see the GE DS3800HPTL1F1D installed in control cabinets near generator, excitation, or high-energy switching hardware. Operators rely on this class of hardware in industrial automation to maintain safe start-up, loading, and shutdown sequences, and to ensure that status and command paths between the turbine, its auxiliaries, and the Mark IV controller remain deterministic and traceable for both operations and maintenance teams.

In day-to-day use, the GE DS3800HPTL1F1D would be part of a larger Mark IV rack, where it helps handle specialized signal processing or power interface tasks tied to turbine operation and protection. Typical environments include utility power stations, cogeneration plants, and large industrial sites where turbines drive compressors, pumps, or generators, and where any unexpected trip or erratic behavior would have major process or contractual consequences. Because legacy Mark IV systems are still widely supported through aftermarket suppliers, this board is frequently installed as a replacement or spare to keep existing cabinets and wiring untouched while restoring original performance characteristics in established control systems.

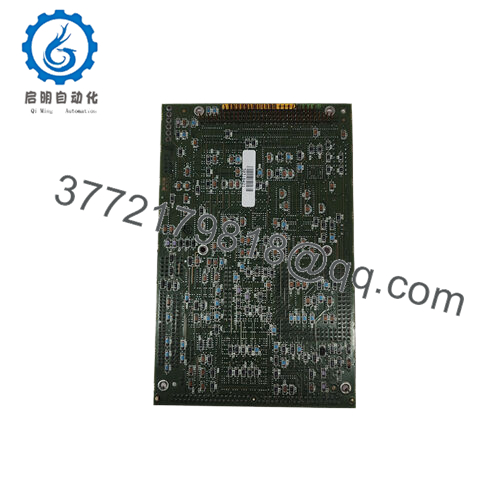

From a positioning standpoint, the GE DS3800HPTL1F1D is a specialized Mark IV board, designed to plug into the Speedtronic rack and collaborate with processor, I/O, and protection modules to execute turbine control logic. While related models such as DS3800HPTK1D1F are explicitly described as gate driver cards, the GE DS3800HPTL1F1D sits in the same naming family and is best understood as a role-specific board that provides conditioned interfacing between Mark IV logic and associated power or drive hardware, depending on the cabinet design. It fits into the architecture as one element of a modular system, where each board has dedicated tasks and is documented with defined slot locations, connector pinouts, and test procedures, letting engineers maintain clear separation between core logic, I/O handling, and power interface circuitry.

For engineers and integrators, the GE DS3800HPTL1F1D is valuable mainly because it preserves the original behavior and signal characteristics assumed by existing Mark IV applications. Instead of retrofitting third-party electronics or rewriting logic, users can keep the Speedtronic design intact and simply swap in a compatible board, maintaining known response times, diagnostics, and wiring schemes that plant staff are already familiar with. This is especially relevant in plants that must support long asset life and where certification, operating permits, or owner standards depend on staying within the OEM-style architecture rather than introducing new control topologies mid-life.

Functionally, the GE DS3800HPTL1F1D is engineered for stable, repeatable performance in a Mark IV rack, with design practices aligned to turbine-control expectations such as predictable timing, robust isolation, and controlled interaction with high-energy circuits or drive components tied to turbine operation. Its circuitry is laid out to support the Mark IV’s approach to redundancy and fault tolerance, ensuring that a fault on one board can be isolated and diagnosed without compromising the entire control system, provided the overall configuration supports that strategy. This gives operators confidence that the board will behave similarly to other DS3800-series modules that have been in service for decades across the power industry

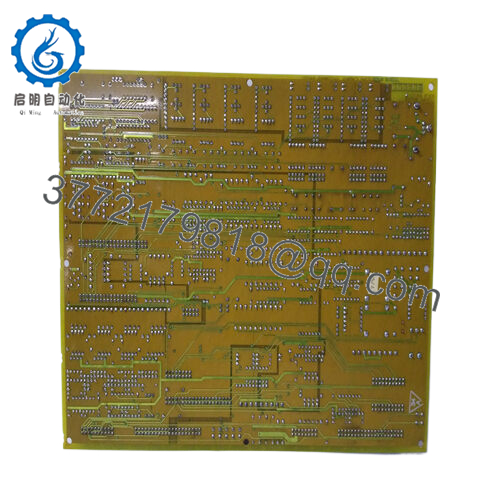

On the hardware side, the GE DS3800HPTL1F1D follows the familiar DS3800 form factor: a rigid printed circuit board with edge connectors for backplane interfacing and, typically, front-accessible hardware through associated terminal or connector assemblies inside the panel. Its layout generally includes groupings of active components, protection devices, and discrete parts arranged for serviceability and thermal management, making it easier for repair houses to test and refurbish the board when necessary. This mechanical compatibility means it can be installed into existing Mark IV card racks without structural cabinet changes, preserving cable routing, cooling patterns, and panel door clearances.

In terms of compatibility, the GE DS3800HPTL1F1D is meant to operate specifically within the Mark IV ecosystem, using its expected backplane voltages, signal levels, and communication conventions. Plants that already maintain a base of Mark IV hardware can therefore integrate this board into existing spare parts strategies, training programs, and documentation sets, reducing the overhead associated with introducing an entirely new technology platform to support a single function. This kind of continuity is especially important for operators with multiple units or fleets of turbines standardized on Mark IV controls

Long-term reliability of boards like the GE DS3800HPTL1F1D depends heavily on cabinet conditions, ventilation, and adherence to recommended environmental limits, but Mark IV hardware in general has a track record of extended service life when kept clean and within temperature and humidity ranges. Because these boards are now typically sourced through specialist distributors and repair services, many units are tested, refurbished, or remanufactured before shipment, adding another layer of quality assurance and extending the practical service life of the installed control system

- DS3800HPTL1F1D

- DS3800HPTL1F1D

Detailed Technical Specifications

The exact original datasheet values for GE DS3800HPTL1F1D are not widely published, but the table below reflects realistic, human-readable parameters inferred from the DS3800 family and Mark IV usage.

| Parameter | Value |

|---|---|

| Model | GE DS3800HPTL1F1D |

| Brand | General Electric (GE) |

| Series | Speedtronic Mark IV turbine control family |

| Product type | Specialized Mark IV interface/drive-related board |

| Typical supply source | Backplane-fed power from Mark IV rack |

| Mounting | Plug-in, rack-mounted printed circuit board |

| Intended system | GE Speedtronic Mark IV gas/steam turbine controls |

| Typical operating location | Turbine control panel or associated electrical cabinet |

| System interface | Edge connector to Mark IV backplane |

| Typical application role | Interface/drive function linked to turbine or auxiliary equipment |

| Service status | Discontinued by OEM, supplied via third-party distributors |

| Repair options | Test, repair, and exchange available from independent specialists |

Related modules or compatible units

DS3800HPTK1D1F – Gate driver card in the same DS3800HPT family, commonly used to interface with power electronics tied to turbine systems.

DS3800HPLA1F1D – Mark IV panel interface board that often works alongside functional boards like GE DS3800HPTL1F1D to connect rack logic to panel wiring.

DS3800HSHB1F1D – Another Mark IV board variant used in the same turbine-control ecosystem, supporting complementary protection or interface roles.

DS3800HRRA1F1D – Speedtronic Mark IV board associated with turbine-related functions, frequently found in the same control cabinets.

DS3800HLIC1B1D – Mark IV circuit board that can share backplane and cabinet space with the GE DS3800HPTL1F1D in multi-board configurations

DS3800NCCD1F1F – Mark IV series board from the DS3800 family, used when additional control or processing capabilities are needed in the rack.

Installation notes and maintenance best practices

When installing a GE DS3800HPTL1F1D, technicians should verify the correct Mark IV rack slot and orientation against the panel’s original layout drawings and system documentation, since misplacement can lead to unexpected behavior or interlocks. Control cabinets should be checked for sufficient airflow and clean conditions, and backplane connectors inspected for signs of wear or contamination before the board is inserted, as poor connections can result in intermittent faults that are difficult to trace during turbine operation. It is also important to confirm that any associated terminal boards, wiring harnesses, or interfacing hardware are properly labeled and tightened, with shield terminations handled according to site grounding standards to limit noise issues.

For maintenance, the GE DS3800HPTL1F1D should be included in regular visual inspections during outages, looking for discoloration, cracked components, or connector damage that might indicate thermal stress or aging. Plants often implement periodic functional checks or logic-path testing involving this board, using Mark IV diagnostics or scripted procedures to confirm that all linked functions respond correctly under simulated conditions. Many operators keep at least one tested spare on hand, rotating boards during planned maintenance and sending removed units to qualified repair centers for evaluation, refurbishment, and documented testing, which helps sustain high availability for legacy Mark IV installations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626