Description

In gas turbine plants where rotors spin at 3,600 RPM and exhaust gases hit 1,200°C, precise hydraulic control keeps fuel flow matched to load demands, preventing overspeed or flameouts during grid transients. Offshore platforms manage actuator pressures across miles of umbilicals, fighting saltwater corrosion and seismic shakes that loosen fittings and spike servos. Refineries sequence compressor trains with micron-level servo positioning, where a millisecond lag means tripped breakers and lost output amid hydrocarbon vapors and arc flashes. These high-stakes arenas call for dedicated hydraulic pressure/temperature modules that sense, amplify, and condition signals from LVDTs and transducers, ensuring servos track commands without drift or noise-induced hunts. Operators seek GE DS3800HPTN1J1H used in industrial automation for its battle-tested role in Speedtronic systems, delivering stable feedback in control systems that safeguard megawatt-scale assets from the first startup through decades of cycling.

Combined cycle units lean on the GE DS3800HPTN1J1H to monitor servo oil temps and pressures, feeding clean data to turbine controllers for anti-hunt damping. In peaking plants, it handles rapid ramps without thermal runaway, while hydro stations use it for governor hydraulics in flood surges. Applicable in control systems from aeroderivatives to frame heavies, the GE DS3800HPTN1J1H cuts nuisance trips by filtering EMI from igniters and VFDs.

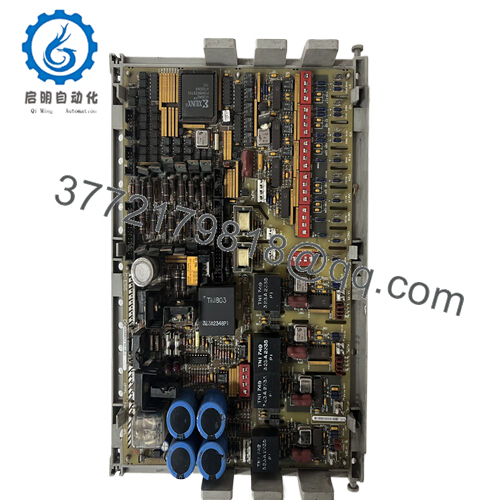

The GE DS3800HPTN1J1H is a hydraulic pressure and temperature interface board from GE’s Speedtronic Mark IV/VE series, tailored for turbine control cabinets where it acquires and preconditions analog signals from hydraulic servos, accumulators, and heat exchangers. Mounted in VME racks alongside core I/O and CPUs, it drives multiplexed channels through opto-isolators and A/D converters, outputting conditioned voltages to the main sequencer via ribbon cables or backplane traces. Within the DS3800 family, the GE DS3800HPTN1J1H anchors the servo loop, supporting 4-20 mA transducers and RTDs for real-time oversight of oil systems critical to fuel stops and variable geometry.

Engineers trust the GE DS3800HPTN1J1H for its plug-and-play fit in legacy Mark IV upgrades, with jumpers for gain tweaks and fault relays that latch on overlimits—streamlining HMI alarms without custom code. It meshes with IS200/EX2100 exciters and ToolboxST software, enabling parameter dumps for predictive swaps. This makes the GE DS3800HPTN1J1H a staple for O&M crews modernizing without full tear-outs, backed by GE’s turbine-specific diagnostics.

Turbine techs highlight the GE DS3800HPTN1J1H‘s signal fidelity: 12-bit resolution on pressure channels rejects noise down to 0.1% span, vital for servo valves holding 300 psi steady amid pump pulsations. Conformal-coated FR4 boards and potted relays endure 85°C oil gallery heat plus 95% humidity, with transient clamps zapping arcs from contactors. Multi-channel muxing cuts wiring bulk, and burnout detection flags failed transducers before loops destabilize.

Physically, the GE DS3800HPTN1J1H latches into standard DS3800 slots with ejector tabs for hot maintenance, its DIN connectors locking against vibration that rattles legacy pins. Low 15W draw shares rack PSUs efficiently, and edge-triggered interrupts prioritize hydraulic faults to the CPU. It speaks Speedtronic protocol natively, daisy-chaining with DS3800A/D packs for full-system views.

Long-haul, the GE DS3800HPTN1J1H logs 150,000+ hour MTBF via screened passives and self-calibrating amps, shrugging off cycles that fry consumer boards. Field reports show 99.9% availability in 10-year fleets, with PROM firmware swaps refreshing diagnostics for newer HMIs.

- DS3800HPTN1J1H

- DS3800HPTN1J1H

Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE DS3800HPTN1J1H |

| Brand | GE (Speedtronic) |

| Type | Hydraulic Pressure/Temperature Board |

| System Platform | Mark IV/VE Turbine Control |

| Power Supply | +5/+15/-15 V DC from rack (15W typ) |

| Operating Temperature | -40°C to 85°C |

| Mounting | VME/DS3800 rack slots |

| Dimensions | 280 mm (W) x 170 mm (H) x 20 mm (D) |

| Weight | 0.6 kg |

| Interfaces | Analog in (4-20mA/RTD), ribbon to sequencer |

| Channels | 8 pressure, 4 temp (configurable) |

| Resolution | 12-bit A/D, ±0.1% accuracy |

| Certifications | UL, CE for turbine environments |

| Cooling | Conduction to rack chassis |

| Environmental Rating | Conformal coated, IP40 equivalent |

Compatible Modules

DS3800HMCN1 – Main control card receiving GE DS3800HPTN1J1H signals for servo loops.

DS3800AIPC1 – A/D pack amplifying GE DS3800HPTN1J1H transducer inputs.

DS3800NDCI1 – Digital combo interfacing with GE DS3800HPTN1J1H fault relays.

IS200TDBH1 – Termination board wiring fields to GE DS3800HPTN1J1H.

DS3800DACN1 – D/A output complementing GE DS3800HPTN1J1H for command signals.

EXC101A – Exciter module sharing rack with GE DS3800HPTN1J1H in full controls.

DS3800SVSJ1 – Servo amp driven by GE DS3800HPTN1J1H feedback.

Verify +15V rails hit 14.5-15.5V on the GE DS3800HPTN1J1H before populating channels, torquing ribbon connectors to 0.4 Nm and strapping shields at 1 m intervals to kill ground loops. Stagger power-up: PSUs first, then I/O boards, scoping signals for 60 Hz rejection >60 dB; jumper mux selects per site prints to match legacy drops. Reserve adjacent slots for airflow, avoiding heat from power relays nearby.

The GE DS3800HPTN1J1H needs monthly scans via Toolbox for drift >0.5% or relay chatter, cleaning gold fingers with isopropyl quarterly—no abrasives on coatings. Log PROM checksums pre-outage, swapping if ECC flags bits; full rack tests mimic transients yearly. Spares rotate every 18 months under bench heat, with GE kits covering common caps—techs resolve 80% faults in under an hour onsite.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626