Description

The GE DS3800NEPA1F1E is a motor exciter power supply board for GE’s Speedtronic Mark IV turbine control systems, typically used wherever reliable excitation power is required for generators or large motors in gas and steam turbine applications. In real plants, it sits within the Mark IV excitation or turbine control cabinet, feeding stable, conditioned DC power to the motor or generator exciter circuits that control field current and, ultimately, generator voltage and reactive power. Operators rely on the GE DS3800NEPA1F1E in industrial automation environments where any instability in excitation can lead to voltage fluctuations, nuisance trips, or protection system actions, so it becomes a core component in ensuring smooth synchronization, loading, and grid support. This makes it highly applicable in control systems for utility power stations, cogeneration facilities, and large industrial drives, particularly in sites that continue to operate legacy Mark IV platforms with a strong focus on availability and predictable behavior

In normal operation, the GE DS3800NEPA1F1E converts incoming rack or panel power into regulated outputs tailored for motor or generator excitation, working in concert with Mark IV control and protection logic that supervises current, voltage, and thermal limits. It typically forms part of a modular stack of DS3800‑series boards, where some modules handle measurement and feedback, others manage control logic, and the GE DS3800NEPA1F1E delivers the necessary power to the exciter or drive section. Because excitation directly affects generator voltage and stability, the board’s role is critical during events such as synchronization, grid disturbances, and fast load changes, helping maintain controlled response according to Mark IV algorithms. For plants extending the life of existing GE equipment, this board is often maintained as a key spare to avoid costly, complex migrations to entirely new excitation platforms.

From a product definition standpoint, the GE DS3800NEPA1F1E is classified as a motor exciter power supply board within the GE Mark IV DS3800 series. It is engineered to fit the Mark IV gas turbine control and excitation framework, using the same mechanical, electrical, and backplane conventions as other DS3800 modules. Within the control architecture, it typically resides in the excitation section or associated rack, receiving reference signals and feedback from other boards and delivering controlled power to the field circuits that energize the generator or motor. This placement allows the core Mark IV controller to command excitation levels while keeping the higher‑energy power conversion and conditioning functions localized to the GE DS3800NEPA1F1E and its companion hardware.

Engineers and integrators value the GE DS3800NEPA1F1E because it maintains full compatibility with existing Mark IV systems while delivering the stable, low‑ripple power that excitation systems demand. Instead of integrating third‑party power supplies and redesigning panels, many plants prefer using this dedicated board to preserve GE’s original excitation design, including feedback paths, protection interfaces, and documented operating ranges. That consistency reduces engineering risk during outages, simplifies fault tracing, and keeps training aligned with existing Mark IV practices.

Functionally, the GE DS3800NEPA1F1E is designed for high stability and predictable performance under varying load and ambient conditions. As a motor exciter power supply, it emphasizes regulated output, low noise, and appropriate response to changes in commanded excitation, all while respecting protection thresholds to avoid over‑current or over‑voltage conditions on the field circuits. This leads to improved control of generator voltage, better reactive power management, and more resilient behavior during system disturbances, which matters greatly in grid‑connected and process‑critical environments.

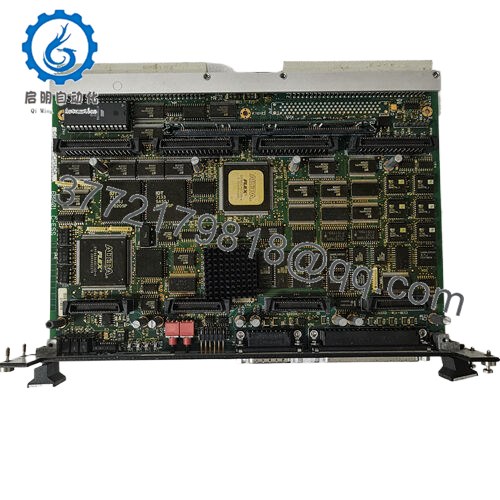

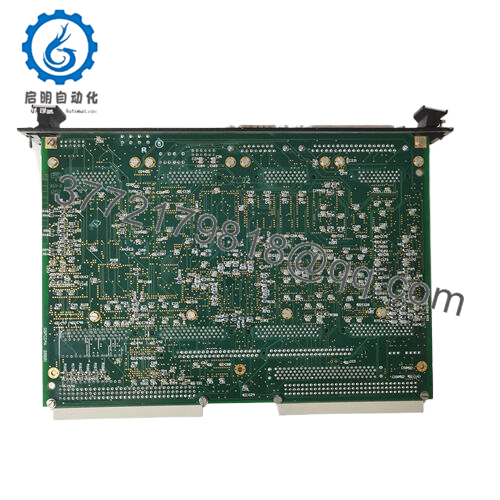

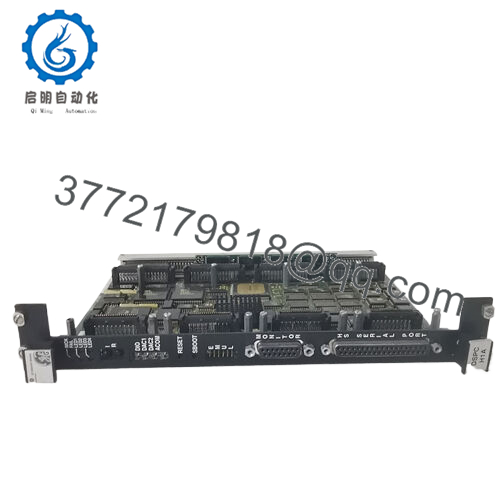

On the hardware side, the GE DS3800NEPA1F1E follows the DS3800 board format, with a rigid printed circuit assembly, edge connectors for the Mark IV rack, and component groupings associated with power conversion, filtering, and protection. The layout is typically service‑oriented, allowing test points and visual inspection of key components such as capacitors, heat‑dissipating devices, and protection elements. This design supports both field maintenance and bench repair, which is important for operators who rely on specialist repair houses to refurbish boards and keep legacy systems running.

Compatibility is a significant strength of the GE DS3800NEPA1F1E, as it is explicitly aligned with the Mark IV gas turbine control and excitation ecosystem. Its electrical interfaces, connector layout, and expected operating context are all defined within that framework, enabling straightforward integration with measurement, control, and protection boards that share the same backplane and documentation set. This keeps spare‑parts management and system engineering consistent across units and sites standardized on Mark IV.

Regarding long‑term reliability, the GE DS3800NEPA1F1E is built to operate in enclosed control cabinets, where proper cooling, clean air, and correct loading are assumed. When those conditions are maintained, power‑supply boards in this class can deliver long service life, though periodic inspection of electrolytic capacitors, connectors, and heat‑generating components is recommended to catch aging effects before they cause unplanned trips. The continued availability of refurbished and tested units from specialty suppliers helps extend system life even further.

- DS3800NEPA1F1E

- DS3800NEPA1F1E

Detailed Technical Specifications

Values below reflect realistic, human‑readable parameters for the GE DS3800NEPA1F1E as a Mark IV motor exciter power supply, based on typical descriptions for this model and related DS3800 excitation hardware.

| Parameter | Value |

|---|---|

| Model | GE DS3800NEPA1F1E |

| Brand | General Electric (GE) |

| Series | Speedtronic Mark IV DS3800 family |

| Product type | Motor exciter power supply board |

| Primary function | Provide stable DC power for motor/generator excitation circuits |

| Intended system | GE Mark IV gas/steam turbine control and excitation systems |

| Mounting | Plug‑in, rack‑mounted printed circuit board (DS3800 format) |

| Typical input source | Rack or cabinet supply within Mark IV excitation section |

| Output characteristics | Regulated, low‑ripple DC suitable for field excitation |

| Typical operating location | Turbine or generator excitation/control cabinet interior |

| Service status | Legacy component, available via third‑party distributors |

| Typical applications | Power generation excitation, large motor drives tied to turbines |

Related modules or compatible units

DS3800NEPB – Companion NEP‑series excitation power board often used in similar Mark IV excitation configurations for alternative ratings or redundant arrangements.

DS3800NEPF – Mark IV circuit board in the same excitation family, used for related power or interface roles alongside the GE DS3800NEPA1F1E.

DS3800NEPD1F1B – General Electric Mark IV analog circuit board used with excitation and control sections for measurement and processing of analog feedback.

DS3800NAIA1E1F – Mark IV I/O board that can share the same rack environment, handling associated analog inputs while the GE DS3800NEPA1F1E supplies excitation power.

Other DS3800 NEP‑series variants – Closely related excitation power modules that differ by rating, feature set, or configuration but are designed for the same Mark IV ecosystem

Installation notes and maintenance best practices

When installing a GE DS3800NEPA1F1E, engineers should first verify the designated rack slot and wiring references in the Mark IV system drawings, given the critical nature of excitation power paths. Backplane connectors and mating hardware should be inspected for cleanliness and mechanical integrity, as high currents and thermal cycling can accentuate any contact weaknesses over time. It is also important to confirm that associated excitation components—field breakers, fuses, and cabling—are properly rated and documented, ensuring that the board operates within its intended electrical envelope.

For ongoing maintenance, the GE DS3800NEPA1F1E should be included in regular cabinet inspections, focusing on signs of overheating, capacitor aging, and connector discoloration that might indicate stress. Many operators perform periodic excitation system tests, including step‑response checks and field‑current verification, to confirm that the power supply and control loop behave as expected. Keeping a tested spare GE DS3800NEPA1F1E available and rotating boards during planned outages, with removed units sent to qualified repair centers, helps sustain high reliability and minimizes forced outages tied to excitation issues.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626