Description

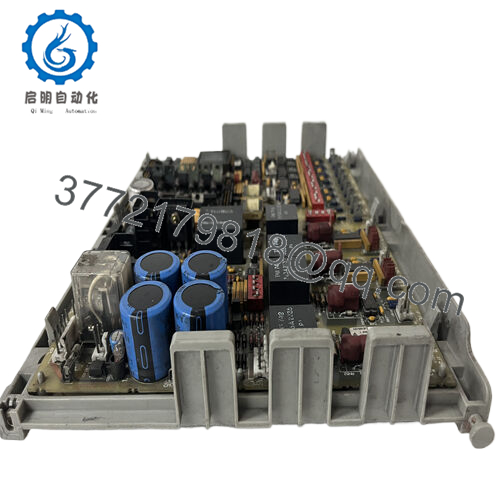

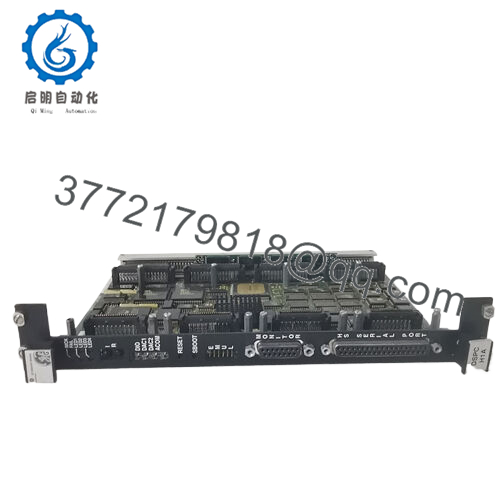

Product Model: GE DS3800NHVE1B1A

Product Brand: General Electric (GE)

Product Series: DS3800 Series

Product Features:

- High-speed PLC processing for complex industrial automation

- Broad compatibility with GE DS3800 modular systems

- Rugged design suitable for harsh industrial environments

- Simplified installation and intuitive maintenance procedures

Technical Specifications Table

| Specification | Details |

|---|---|

| Model | GE DS3800NHVE1B1A |

| Series | DS3800 |

| Processor Type | High-speed PLC CPU |

| Memory | 2 MB user program memory |

| Communication Ports | Ethernet/IP, Modbus RTU, RS-232/485 |

| Input Voltage | 24V DC |

| Operating Temperature | 0–60°C (standard), -20–70°C (extended option) |

| I/O Capacity | Up to 256 digital I/O points |

| Mounting | DIN rail / Panel mount |

| Diagnostics | LED indicators, error logs |

| Expansion Modules | Compatible with DS3800 series I/O modules |

| Firmware | Ladder logic, Structured Text |

| Certifications | CE, UL, RoHS compliant |

- DS3800NHVE1B1A

Technical Features & Benefits

The GE DS3800NHVE1B1A delivers industrial-grade performance in a compact, modular package. Its high-speed processor allows rapid execution of complex logic routines, ensuring precise control over multi-step manufacturing and processing operations. Engineers appreciate its robust diagnostics system, capable of monitoring I/O modules, network communications, and system health in real time.

Built for demanding environments, the module withstands high vibration, temperature variations, and electrical noise. Its firmware supports multiple programming languages, including ladder logic and structured text, making it adaptable for engineers familiar with varied automation standards. Beyond performance, the GE DS3800NHVE1B1A facilitates predictive maintenance, providing alerts for potential failures before they disrupt production. This capability has proven invaluable in continuous process industries, such as chemical and food processing plants, where uptime is critical.

Field technicians often highlight the module’s clear LED indicators, modular connectors, and simplified wiring as factors that reduce troubleshooting time. Integration with GE’s HMI and remote monitoring systems allows operators to track production efficiency, energy consumption, and machine health in real time, aligning with modern Industry 4.0 strategies.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626