Description

In gas and steam turbine control systems, interfacing safely and reliably with high-voltage signals from field devices—such as potential transformers, current sensors, or exciter feedback—is crucial for accurate monitoring, protection, and closed-loop regulation. Poor isolation or conditioning of these signals can lead to measurement errors, ground loops, electromagnetic interference, or even damage to low-voltage control electronics during faults or surges. The GE DS3800NHVK1A1A addresses this need as a dedicated high-voltage interface board in GE’s Speedtronic Mark IV turbine control systems, providing galvanic isolation, signal scaling, and robust protection for high-voltage inputs.

This board becomes essential in environments where turbines operate with medium to high-voltage auxiliaries, such as in Load Commutated Inverter (LCI) drives or synchronous machine interfaces requiring precise voltage and current feedback. In industrial automation and process control setups involving large generators or motors, unreliable high-voltage signal handling can compromise synchronization, cause protective misoperations, or reduce overall efficiency. The GE DS3800NHVK1A1A ensures signal reliability through optical or barrier isolation, supporting fault-tolerant operation in noisy electrical settings common to turbine halls.

Engineered for sustained exposure to vibration, thermal cycling, and high electrical stress, it maintains I/O signal integrity in critical applications. Whether sustaining legacy Mark IV panels or integrating into hybrid upgrades, the GE DS3800NHVK1A1A contributes to system stability, high reliability, and safe high-voltage management in industrial automation contexts.

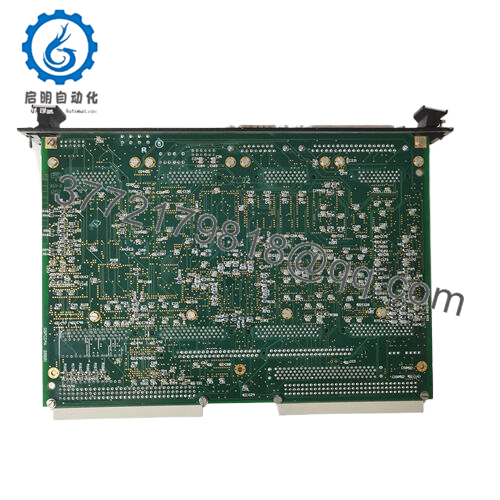

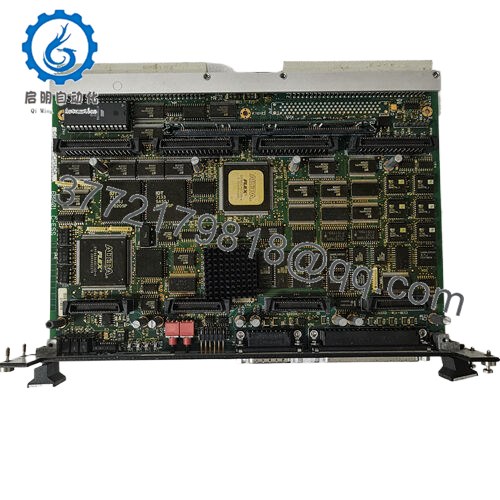

The GE DS3800NHVK1A1A functions as a high-voltage interface card in the Mark IV rack, accepting inputs from high-potential sources and conditioning them for the main control processors. It uses onboard diodes, capacitors, and isolation components to scale voltages, suppress transients, and provide directional current flow, delivering clean analog signals to downstream I/O or regulator boards.

Within the automation stack, it resides in the interface section alongside other protection and conditioning modules, connecting via ribbon cables or backplane for data transfer over the Mark IV bus. The board features multiple diodes for rectification and protection, capacitors for energy storage and filtering, relays for switching, and LED indicators for channel status and fault detection.

It supports integration in redundant setups, where parallel boards enhance availability during high-voltage monitoring tasks like generator synchronization or drive control. Positioned between field wiring and digital logic, the GE DS3800NHVK1A1A acts as a protective barrier, ensuring safe translation of high-voltage parameters into usable data while feeding diagnostic information back to the control core in process control environments.

- DS3800NHVK1A1A

| Specification | Details |

|---|---|

| Model Number | DS3800NHVK1A1A |

| Brand | GE (General Electric) |

| Type | High Voltage Interface Board |

| Input Voltage | Up to high voltage ranges (field-dependent, isolated) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | Rack-mounted with corner screws |

| Dimensions | Approx. 12 x 9 inches (standard DS3800 form) |

| Weight | Approx. 1.5 kg |

| Interface/Bus | Ribbon cables, backplane connectors, multi-pin ports |

| Compliance | Industrial standards (legacy GE turbine systems) |

| Supported Protocols | Mark IV proprietary bus |

| Typical Power Draw | Under 30W |

Opting for the GE DS3800NHVK1A1A equips your system with a component engineered for robust high-voltage isolation, directly enhancing measurement accuracy and protecting sensitive electronics from surges or faults. Its comprehensive diode and capacitor array filters noise effectively, resulting in stable feedback loops that improve turbine response and reduce oscillations during load changes.

In practice, this translates to fewer false trips, consistent synchronization performance, and extended component life in high-stress applications. The visible LED diagnostics accelerate issue resolution, minimizing diagnostic time and supporting efficient turnaround during planned outages.

Compatibility with standard Mark IV connectors simplifies replacements, cutting engineering overhead and preserving existing configurations. Long-term, the GE DS3800NHVK1A1A demonstrates resistance to environmental degradation, ensuring reliable operation and lower maintenance demands in industrial automation settings where high-voltage integrity is paramount.

The GE DS3800NHVK1A1A is frequently used in power generation plants with GE heavy-duty gas turbines, where it interfaces high-voltage signals from generator PTs/CTs or LCI systems under demanding conditions of vibration and electrical noise, supporting critical system uptime.

It also appears in combined-cycle facilities for synchronous clutch or exciter monitoring, providing isolated feedback in high-temperature environments. In industrial drive applications, such as pipeline compressors or mill motors, the board handles voltage inputs for precise control in process control environments used in power plants and heavy manufacturing.

Across these sectors, the GE DS3800NHVK1A1A delivers high reliability for managing elevated potentials while maintaining fast, accurate data cycles essential for turbine protection and optimization.

DS3800NHVK – Base model without specific revision suffixes for general high-voltage applications

DS3800NHVL1C1C – LCI-focused variant for drive-specific interfacing

DS3800NHVM1E1C – Related high-voltage module with additional filtering options

DS3800NHVN1A1A – Network-oriented high-voltage board for expanded connectivity

DS3800NHVD1E1E – Protection-heavy version with higher resistor ratings

DS3800NHVE1A1A – Earlier generation high-voltage card for legacy racks

DS3800NHVP1B1B – Power supply interface companion for voltage regulation

Before fitting the GE DS3800NHVK1A1A, confirm rack position and connector alignment with your Mark IV layout, verifying that field wiring matches isolation ratings to prevent overvoltage risks. Ensure proper grounding and sufficient cabinet ventilation, as high-voltage components can generate localized heat.

Handle carefully to avoid static discharge on sensitive diodes, and secure all multi-pin connections without over-tightening. Post-installation, observe LEDs during power-up for normal indication and perform basic isolation tests if accessible.

Maintenance typically includes periodic connector inspections for oxidation in corrosive atmospheres, dust removal from capacitor areas, and LED pattern checks during operation. Yearly high-potential testing or visual review of relays helps preempt issues. With good cabinet practices, this board demands little routine intervention in turbine control installations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626