Description

In turbine halls where every second of uptime counts, power supply stability under extreme vibration and thermal stress separates reliable operations from costly scrams. Operators turn to the GE DS3800NPSE1C1B in GE Mark IV turbine control systems powering gas and steam units, ensuring clean DC rails feed critical processors, excitation boards, and sequence logic without glitches during startups, full-load runs, or grid faults. Whether stabilizing a peaking plant’s combustion turbine amid rapid ramps or backing synchronous generators in combined-cycle facilities, this board keeps the control core alive so protective trips stay sharp and process variables hold steady.

The GE DS3800NPSE1C1B deploys in high-reliability setups like offshore platforms or utility baseload stations, where redundant power paths prevent single-point failures from halting multimillion-dollar assets. In retrofit scenarios, maintenance teams slot it into aging Speedtronic racks to replace drifted originals, preserving native logic while dodging full-system migrations. Its role proves vital in coordinating fuel valves, speed governors, and vibration monitors, turning raw AC input into isolated, regulated outputs that shield sensitive electronics from plant noise and surges. Engineers specify the GE DS3800NPSE1C1B for industrial automation in power gen, valuing how it anchors the Mark IV architecture amid dusty enclosures and 24/7 thermal cycles.

Product Introduction & Positioning

The GE DS3800NPSE1C1B is a rugged power supply board from GE’s DS3800 lineup, engineered for the Mark IV turbine management platform where it converts plant AC to multiple isolated DC voltages for the control rack. It anchors the base layer of the system, feeding CPUs, I/O modules, and field interfaces with low-ripple power that supports deterministic execution in safety-critical loops. Positioned upstream of excitation and protection cards, it ensures voltage sags or spikes never compromise turbine sequencing or overspeed safeguards.

Within the card cage, the GE DS3800NPSE1C1B integrates via backplane rails, often paralleled with mates for redundancy to hit 99.999% availability targets in prime movers. Its design caters to integrators modernizing legacy fleets, offering form-fit swaps that retain pinouts and derates for hot environments. What sets it apart is fault-tolerant output staging—prioritizing core rails during brownouts—which lets partial failures isolate without full shutdowns, a boon for plants chasing longer run intervals.

For end users, the GE DS3800NPSE1C1B embodies GE’s field-proven ethos in control systems, blending overspec’d filtering with diagnostic relays that signal degradation early. It fits seamlessly into DCS-tied turbine islands, enabling historians to log power events for root-cause analysis on excursions

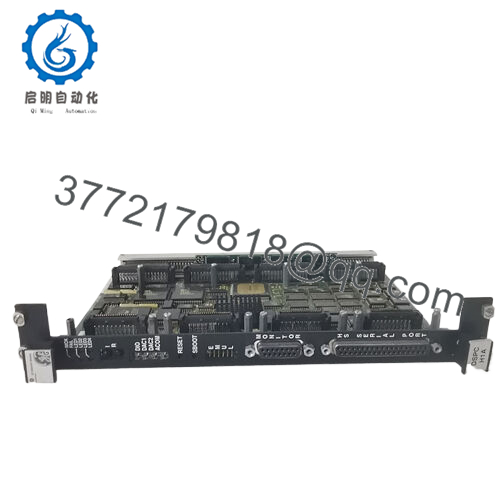

- DS3800NPSE1C1B

Key Technical Features & Functional Benefits

The GE DS3800NPSE1C1B delivers rock-solid regulation across ±5%, ±15V, and +5V rails, shrugging off input swings from generator bus noise or utility flickers to keep turbine logic synced. Built-in crowbar circuits dump faults instantly, protecting downstream boards from overvolt spikes during thyristor arcs or lightning hits. Operators gain peace from green LEDs tracking each rail, cutting debug time on night shifts.

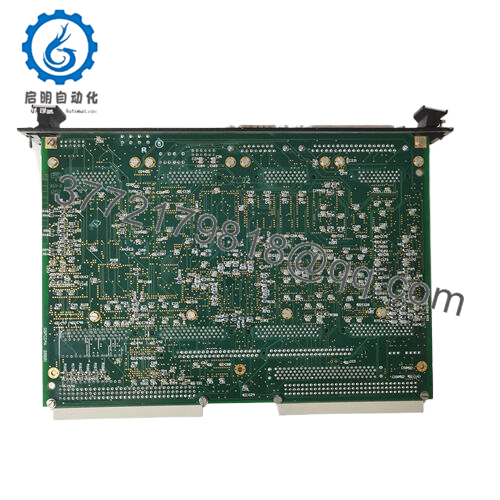

Ruggedized for turbine bays, the GE DS3800NPSE1C1B uses conformal-coated boards and potted transformers to fend off humidity, salt air, and 50g shocks, mounting securely in VME-style cages with minimal panel depth. Its efficiency curbs cabinet heat, easing cooling loads in sealed enclosures near hot exhaust paths. Watchdog outputs tie into system health buses, auto-alarming on drift via host processors.

Backplane compatibility shines with the GE DS3800NPSE1C1B, hot-swappable under load in redundant pairs and fusing inputs to block cascade faults. It powers full Mark IV stacks— from <C> core to <D> sequencers—without custom hacks, streamlining multisite spares. Protocols like discrete status lines feed SCADA for remote oversight.

Longevity comes from mil-spec caps and derated semis targeting 50,000 hours MTBF, matching overhaul cadences. Self-resetting fuses and thermal cutouts enable graceful recovery post-surge, slashing MTTR in remote sites.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE DS3800NPSE1C1B |

| Brand | General Electric (GE) |

| Type | Turbine control power supply board |

| Power Supply Input | 115/230 VAC nominal, 47-63 Hz |

| Outputs | +5V, ±15V DC regulated |

| Operating Temperature | -20 to 70 degrees Celsius |

| Mounting | Mark IV card rack/cage |

| Dimensions | Standard DS3800, approx. 260 x 130 x 50 mm |

| Weight | Approximately 1.2 kg |

| Interfaces | Backplane power bus, status discretes |

| Certifications | Industrial/power gen compliant |

| Cooling | Forced air via rack fans |

| Environmental Rating | Coated for harsh industrial use |

| Efficiency | >80% typical |

| Fault Protection | Crowbar, thermal, overcurrent |

Related Modules or Compatible Units

GE DS3800NMEA1HEF – Excitation board powered by the GE DS3800NPSE1C1B for field regulation in turbine gensets.

GE DS3800NMEA1P1J – Matching excitation variant drawing stable rails from the GE DS3800NPSE1C1B in Mark IV cores.

GE DS3800HMHA1E – Auxiliary supply companion buffering loads alongside the GE DS3800NPSE1C1B.

GE DS3800NPSE1C1C – Updated power board sibling with extra redundancy tying to the GE DS3800NPSE1C1B.

GE IS200EPSMG2 – EX2100-era upgrade path from GE DS3800NPSE1C1B systems for modern turbines.

GE DS3800HMPA – Protection module fed reliably by the GE DS3800NPSE1C1B during fault clears.

GE DS3800NDCI – I/O interface relying on GE DS3800NPSE1C1B outputs for field signals

Installation Notes & Maintenance Best Practices

Teams slot the GE DS3800NPSE1C1B into designated rack positions after de-energizing, verifying torque on power stabs and aligning with redundant mates for N+1 coverage. Pre-install, scope input AC for clean sinusoids and bond chassis ground to station earth, spacing it from noisy bridges by filler cards. Rack fans must spin free, and voltage checks confirm rails before tying logic boards—mismatches fry EPROMs fast.

Quarterly, peek inside for fan dust or cap weepage, loading test sets to stress rails under simulated loads. Log ripple via scope during annuals, swapping if >50mVpp; cycle power 50x to vet crowbars. Refurbs from vetted shops restore to spec, but always re-baseline post-swap against turbine logs for anomalies.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626