Description

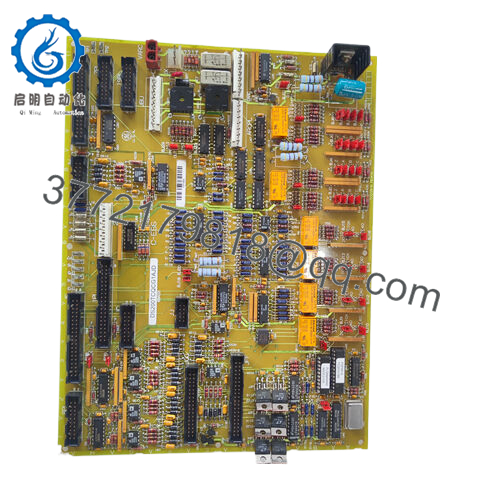

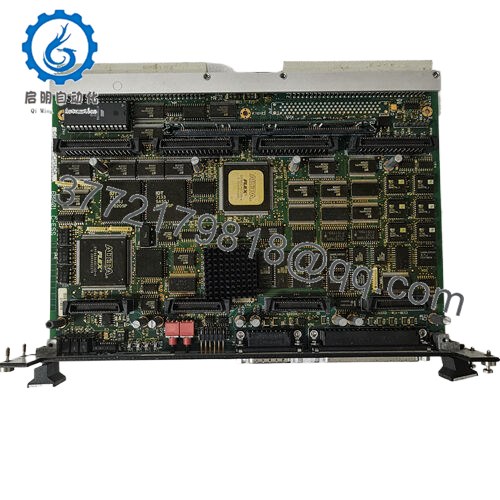

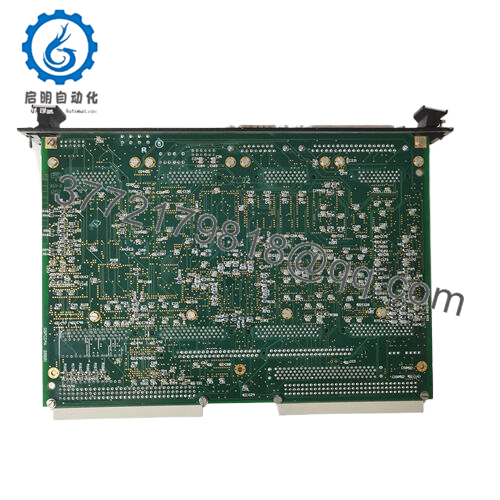

In legacy GE Speedtronic Mark IV turbine control systems, reliable DC power distribution to rack-mounted cards is fundamental to preventing control interruptions, especially in high-vibration environments like gas or steam turbine halls where voltage sags or noise can corrupt signals and trigger false trips. Aging power supplies often exhibit capacitor degradation or fuse issues, leading to unstable ±15V, +5V, or +24V rails that affect processor voting, I/O accuracy, and overall system fault tolerance. Situations such as extended baseload operation, frequent starts/stops, or integration with modern monitoring tools frequently demand upgraded power conditioning for sustained performance. The GE DS3800NPSF1C1B addresses this as a dedicated power supply board tailored for the DS3800 series, delivering regulated low-voltage outputs with filtering to ensure clean power delivery across the backplane. Engineered for industrial automation and process control in power generation, it supports the high reliability required in triple modular redundant setups, minimizing downtime risks and extending system life in critical turbine applications. In process control environments where consistent power rails are essential for signal integrity and processor synchronization, the GE DS3800NPSF1C1B proves vital for maintaining operational stability without external conditioning hardware.

The GE DS3800NPSF1C1B functions as a secondary or auxiliary power supply board in the Mark IV Speedtronic rack, mounting via edge connectors to the parallel backplane and distributing conditioned DC voltages to adjacent control and I/O cards. It converts and regulates rack input power—typically from primary supplies—into stable outputs for logic and analog circuits, incorporating filtering components to suppress ripple and transients common in turbine electrical environments. Positioned typically in the power distribution section of the stack, it works alongside primary units like NPSY or NPSE variants, feeding the common bus that supports TMR voting among processor cards. The board includes overcurrent protection, fuse points, and test points for verification, allowing integration in both simplex and redundant configurations without external protocols—operating natively over the Mark IV bus structure. In the broader automation architecture, the GE DS3800NPSF1C1B resides at the power conditioning level, ensuring reliable supply to critical paths like excitation regulators or signal isolators, facilitating precise turbine control and rapid response to load changes.

| Specification | Details |

|---|---|

| Model Number | DS3800NPSF1C1B |

| Brand | General Electric (GE) |

| Type | Power Supply Board |

| Input Voltage | 120 V AC / DC (typical Mark IV rack) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | Rack-mounted PCB with edge connectors |

| Dimensions | Approx. 8.25 in x 4.18 in (standard DS3800 form factor) |

| Weight | Approx. 0.8 lb |

| Interface/Bus | Mark IV parallel backplane |

| Compliance | UL, CSA (typical for era) |

| Supported Protocols | N/A (native Speedtronic bus) |

| Typical Power Draw | ~10–15 W |

- DS3800NPSF1C1B

Choosing the GE DS3800NPSF1C1B means securing a power solution engineered for the rigors of turbine control, where stable DC rails directly contribute to fault-tolerant operation and extended equipment longevity. Its robust filtering and regulation reduce engineering overhead by eliminating the need for add-on conditioners, delivering performance consistency even amid electrical noise from nearby generators or switchgear. In real deployments, this translates to fewer nuisance trips, preserved calibration in analog paths, and smoother TMR voting during transients. Maintenance efficiency improves through accessible fuses and test points, enabling quick diagnostics without rack disassembly. The GE DS3800NPSF1C1B offers tangible value by supporting seamless upgrades in legacy systems, lowering both commissioning time and long-term operational vulnerabilities in demanding power generation settings.

The design of the GE DS3800NPSF1C1B prioritizes durability, with components chosen to handle thermal cycling and vibration, ensuring reliable power delivery that upholds critical system uptime over decades of service.

The GE DS3800NPSF1C1B finds frequent use in large-frame gas and steam turbine installations within power plants, supplying clean power to control racks under conditions requiring continuous uptime and resilience to harsh ambient factors. In combined-cycle facilities, it supports stable operation during load following, preventing voltage fluctuations that could disrupt synchronization or protection logic. Oil and gas turbine-driven generators often incorporate it for remote sites, where its filtering capabilities maintain control integrity despite power quality issues from local grids. Refineries and petrochemical plants deploy the board in process control environments for turbine-powered compressors, benefiting from its role in sustaining fast control loops and high reliability amid electrical disturbances typical of heavy industrial sites.

DS3800NPSE1D1F – Primary power supply variant for main rack distribution.

DS3800NPSK1 – Compact power supply board for auxiliary rails.

DS3800NPSM1F1D – Power supply panel with expanded output capacity.

DS3800NPPB1M1K – Regulator-integrated power board for specific sections.

DS3800NPSV – Versatile power supply module for varied voltage needs.

DS3800NPSR – Related supply card often used in redundant pairs.

DS3800NPSS1G1F – Higher-output version for dense card configurations.

Before installing the GE DS3800NPSF1C1B, verify revision compatibility with your Mark IV rack layout, as suffix variations can affect output connectors or fuse ratings. Check primary supply health to avoid overloading, and ensure proper rack ventilation given the board’s moderate heat dissipation under load. Inspect for any required jumper settings based on adjacent cards, and confirm backplane cleanliness to prevent poor contacts. During setup, measure output voltages at test points prior to powering the full rack, and seat edge connectors securely to withstand ongoing vibration. For maintenance, visually check fuses and capacitors during routine outages, and annually verify rail stability under simulated load to detect early drift. This methodical care sustains the board’s reliability in long-term turbine service.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626