Description

In legacy GE Speedtronic Mark IV turbine control systems, integrating servo valve actuators for precise positioning of fuel valves, inlet guide vanes, or bypass valves often presents challenges in environments with high electrical noise, vibration, and demanding response times. Standard interface cards can suffer from signal drift, poor isolation, or insufficient drive current, leading to unstable valve positioning, hunting, or even emergency trips during critical load changes. These issues are particularly acute in large-frame gas turbines operating under variable conditions or in combined-cycle plants requiring tight synchronization. The GE DS3800NSMA1B1B addresses this directly as a dedicated servo motor actuator interface board, providing conditioned drive signals and feedback processing for LVDT/RVDT-based positioners with the robustness needed for industrial automation and process control. Built for the DS3800 series, it ensures accurate, repeatable valve control while supporting the system’s TMR architecture for high reliability. In turbine setups where precise actuator response is essential for efficiency and safety, the GE DS3800NSMA1B1B becomes a key component for maintaining stable operation and reducing calibration downtime.

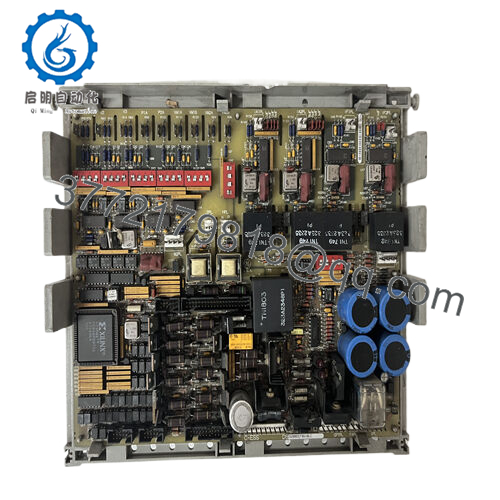

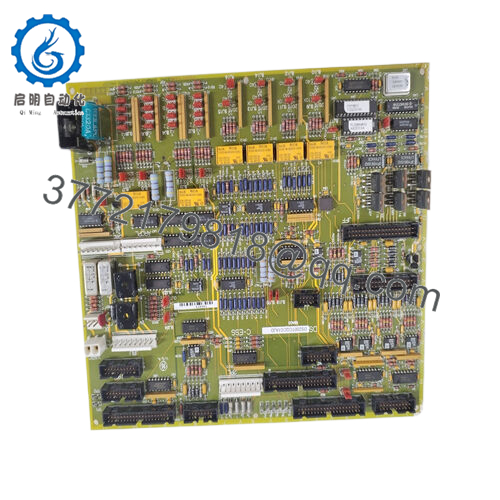

The GE DS3800NSMA1B1B serves as a servo interface board in the Mark IV Speedtronic rack, connecting via edge connectors to the parallel backplane and interfacing with processor, regulator, and I/O cards. It drives servo coils with amplified current outputs while processing position feedback from LVDTs or similar transducers, closing the loop for proportional control of hydraulic or electric actuators. Positioned in the servo control section of the stack, it receives command signals from the main controllers and provides closed-loop adjustment, often with gain and offset tuning via onboard potentiometers. The board supports TMR voting for redundancy, ensuring continued operation even if one channel faults, and includes isolation to protect against ground loops or noise ingress common in turbine halls. Native to the Mark IV bus, it features diagnostic test points and status LEDs for verification without external tools. In the overall automation stack, the GE DS3800NSMA1B1B bridges digital sequencing logic to analog actuator hardware, enabling fast, precise response in fuel control, bleed valve management, or variable geometry systems across simplex or redundant configurations.

| Specification | Details |

|---|---|

| Model Number | DS3800NSMA1B1B |

| Brand | General Electric (GE) |

| Type | Servo Motor Actuator Interface Board |

| Input Voltage | 120 V AC (typical Mark IV rack supply) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | Rack-mounted PCB with edge connectors |

| Dimensions | Approx. 8.25 in x 4.18 in (standard DS3800 form factor) |

| Weight | Approx. 0.8 lb |

| Interface/Bus | Mark IV parallel backplane |

| Compliance | UL, CSA (typical for era) |

| Supported Protocols | N/A (native Speedtronic bus) |

| Typical Power Draw | ~12–15 W |

Selecting the GE DS3800NSMA1B1B delivers servo control reliability engineered for turbine dynamics, where accurate positioning directly influences combustion stability, emissions compliance, and overall plant efficiency. Its isolation and drive capabilities minimize signal interference, ensuring long-term performance without frequent recalibration or drift under thermal cycling. This reduces engineering overhead during system tuning or retrofits, as the board integrates seamlessly into existing racks with standard adjustments. In operation, it provides smooth, responsive actuator movement that prevents overshoot or oscillation, protecting mechanical components and extending service intervals. Maintenance efficiency improves through accessible test points and straightforward layout, allowing rapid fault isolation without disrupting the process. The GE DS3800NSMA1B1B brings practical value by supporting modular servo expansions, lowering integration complexity and operational risks in high-availability power generation.

The board’s design also enhances performance consistency in noisy or vibration-intensive settings, maintaining tight control loops for optimal turbine response across load ranges.

The GE DS3800NSMA1B1B is frequently deployed in heavy-duty gas and steam turbine applications within power plants, interfacing with servo actuators for critical positioning under demands for continuous uptime and precise control. In combined-cycle operations, it ensures stable fuel valve modulation during load ramps, supporting grid stability and rapid frequency response. Oil and gas turbine-driven compressors often use it in upstream or pipeline service, where its robustness handles remote, harsh conditions with minimal maintenance access. Petrochemical facilities rely on the board in process control environments for actuator management on blowers or pumps, delivering the fast, accurate feedback needed for uninterrupted production in electrically challenging sites.

- DS3800NSMA1B1B

DS3800NSCC1D1D – Current sensing variant for servo monitoring.

DS3800NSWB1C1B – Related switching board for auxiliary servo paths.

DS3800NVAA1E1C – Voltage-to-analog converter often paired for feedback.

DS3800HSCA1G1D – High-speed signal conditioning card in servo loops.

DS3800HIMA1A1A – Isolation module used with servo interfaces.

DS3800DSQD1A1B – Sequencer auxiliary board for coordinated actuator control.

DS3800HSAA1D1C – Servo amplifier variant with similar integration.

Before installing the GE DS3800NSMA1B1B, confirm revision compatibility with your Mark IV rack and connected actuators, as suffix changes can impact gain settings or connector assignments. Verify rack power quality and ensure adequate cooling airflow, given the board’s heat output during full drive conditions. Check for proper jumper configurations based on LVDT excitation needs, and clean backplane contacts to prevent signal issues. During commissioning, calibrate outputs using test points with a known position reference, and firmly seat edge connectors to counter vibration effects. For ongoing maintenance, inspect potentiometers for drift and capacitors for signs of stress during outages, while annually verifying loop response with simulated commands. This disciplined maintenance preserves the board’s precision over extended turbine service.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626