Description

In power plants where turbine governors demand split-second response to load swings, or in heavy process industries juggling steam flows and pressure cascades, control hardware must shrug off vibrations, heat buildup, and electrical transients without skipping a beat. Engineers turn to modules like the GE DS3815PMMA1C1B for these exact scenarios—think gas-fired combined cycle units, petrochemical refineries, or pulp and paper mills where a single module failure could idle multimillion-dollar assets for hours. This board steps in to manage pulse modulation tasks, ensuring actuators and valves track setpoint changes precisely amid noisy field conditions

The GE DS3815PMMA1C1B thrives in distributed control setups, linking field transducers to supervisory layers while filtering out glitches that plague lesser components. Operators in steel rolling mills or wastewater treatment facilities deploy it to synchronize servo loops, handle thyristor firing for drives, and maintain stable excitation signals in generator bays. Its role shines during startups, where ramping exciters or sequencing boilers requires ironclad timing to avoid overshoots or trips. Maintenance crews appreciate how it flags anomalies early, cutting diagnostic time on crowded panels shared with relays, power supplies, and I/O racks.xlykj01.jdzj+1

What sets the GE DS3815PMMA1C1B apart in industrial automation is its native fit within legacy Mark IV and compatible Speedtronic architectures, now often retrofitted into modern hybrids with Ethernet gateways. It supports clean integration into turbine control cabinets, where space is tight and uptime metrics rule every decision. Across brownfield upgrades in oil and gas compression stations or cement kilns, this module delivers the deterministic behavior that lets teams push equipment harder without risking instability.

Product Introduction & Positioning

The GE DS3815PMMA1C1B functions as a pulse modulation and power management module within GE’s robust Speedtronic control series, primarily for turbine and drive regulation systems. It generates precise firing pulses for thyristor bridges, handles feedback from current transformers, and coordinates with core controllers to regulate excitation or speed in real-time applications. Positioned midstream in the control chain, it bridges raw power electronics to higher-level logic, making it indispensable for systems demanding high-fidelity actuator control.

In a full architecture, the GE DS3815PMMA1C1B mounts alongside ionizer boards, trip relays, and servo amps in a card-cage setup, feeding processed signals upward to HMI panels or DCS hosts. This placement optimizes latency for closed-loop tasks like AVR tuning or load sharing in paralleled gensets. For integrators modernizing older plants, its drop-in compatibility reduces recertification hassles while enabling hybrid networks that blend <I/O with Profibus or Modbus overlays

Engineers value the GE DS3815PMMA1C1B for its battle-tested firmware that prioritizes fault tolerance over bells and whistles—think automatic pulse inhibition during faults or self-resetting protections that keep processes online. In environments where mean time between failures directly hits profitability, this module’s straightforward diagnostics and field-proven stability make it a go-to for panel builders handling OEM skids or end-user retrofits

- DS3815PMMA1C1B

Key Technical Features & Functional Benefits

Engineers specify the GE DS3815PMMA1C1B when pulse accuracy and noise rejection are make-or-break, as it delivers microsecond-level firing resolution for SCRs even under 10% line dips or EMI spikes from adjacent switchgear. Cycle times hold steady at 10-20 ms, supporting multi-axis coordination without jitter that could desync governors or exciters. This predictability scales to demanding loads, like 100 MW turbine ramps where overshoot risks grid penalties.

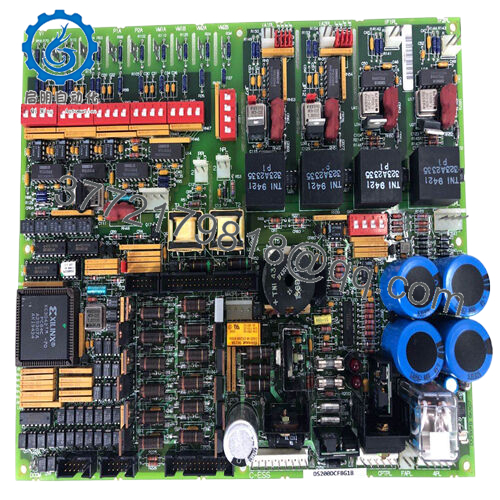

Built for cabinets baking at 50°C with motor starts hammering the bus, the GE DS3815PMMA1C1B packs conformal-coated PCBs into a standard 6U form factor, DIN-rack adaptable with minimal panel mods. Vibration tolerance hits 5G across 5-500 Hz, and its fiber-optic pulse links sidestep ground loops that plague copper runs in motor control centers. Connectors use locking MIL-spec types, easing swaps during live outages if fuses stay cool.

Broad protocol support lets the GE DS3815PMMA1C1B handshake natively with Mark V/VI cores, plus gateways to Ethernet/IP or Profinet for SCADA tie-ins. It mates seamlessly with GE’s DS3800/DS3810 family, sharing diagnostics over backplane buses for holistic health monitoring. In mixed-vendor plants, isolation transformers pair it with ABB or Siemens drives without waveform distortion

Reliability shines through MTBF ratings exceeding 100,000 hours, backed by over-spec’d caps and optos that outlast thermal cycling in dusty atmospheres. Diagnostics expose pulse stats, fault latches, and thermal margins via serial ports, empowering remote polls that preempt 80% of service calls. Over decades in hydro or fossil fleets, these traits minimize scrap rates from erratic modulation

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE DS3815PMMA1C1C1B |

| Brand | General Electric (GE) |

| Product Type | Pulse Modulation Power Module |

| Power Supply Voltage | 125 V direct current / 115 V alternating current |

| Operating Temperature Range | -30 °C to +65 °C |

| Storage Temperature Range | -40 °C to +85 °C |

| Mounting Method | Card rack / DIN rail compatible |

| Enclosure Protection Rating | IP20 (panel-mounted) |

| Typical Power Consumption | 25 W maximum |

| Dimensions (W x H x D) | 260 mm x 200 mm x 50 mm (approx.) |

| Approximate Weight | 1.2 kg |

| Interfaces | Backplane bus, fiber optic pulse out, serial diagnostics |

| Certifications | UL, CE, EMC Class A |

| Cooling Method | Forced air via rack fans |

| Environmental Rating | 5% to 95% non-condensing humidity |

Related Modules or Compatible Units

DS3815PDPA1B – Preamp companion for signal conditioning ahead of the GE DS3815PMMA1C1B in excitation chains.

DS3800NHVM1C – High-voltage interface that feeds raw power into the GE DS3815PMMA1C1B for SCR bridging.

DS3815DMCC – Digital core module pairing with GE DS3815PMMA1C1B for full Mark IV turbine loops.

IC600YB945 – ASCII handler extending comms from the GE DS3815PMMA1C1B to legacy PLCs.

DS200EXPSG1A – Exciter supply syncing pulses from the GE DS3815PMMA1C1B in genset apps.

DS3815PCMA1E – Similar power card for redundant setups alongside GE DS3815PMMA1C1B.

6BA02 – I/O base that expands field terminations for the GE DS3815PMMA1C1B platform.

Installation Notes & Maintenance Best Practices

Site surveys before dropping in the GE DS3815PMMA1C1B should map rack slot power budgets, ensuring 28 V rails stay above 24 V under inrush from neighbors like servo cards. Ground planes demand low-impedance bonds to chassis, with shield drains tied at one end only to dodge loops—critical in plants with VFD harmonics cooking cables. Leave 50 mm vent paths clear, and torque fiber ports to 0.5 Nm to seal against fiber grime in coal-dust zones.

Quarterly walkdowns catch early tells: scan for hot spots via IR gun, toggle test points for pulse symmetry, and dump fault buffers over RS-485 before they wrap. Firmware parity checks during annual outages guard against bit flips from cosmic rays in high-altitude hydro sites. Swapping demands ESD straps and live-bus lockout; post-install, baseline waveforms on a scope to trend degradation before it bites availability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626