Description

In industrial automation systems where legacy Series 90-30 platforms need modern networking without a full migration, engineers frequently face challenges integrating Ethernet-based communications, data exchange with higher-level systems, or web-enabled monitoring while maintaining fast scan times and sufficient memory for evolving logic. Older CPUs often lack native high-speed Ethernet, forcing add-on modules that consume slots, increase complexity, and slow performance in distributed I/O setups. This becomes critical in process control environments requiring seamless connectivity to SCADA, HMIs, or enterprise networks alongside deterministic execution for reliable signal handling. The GE Fanuc IC693CPU374-GS delivers a high-performance solution as a single-slot CPU in the Series 90-30 family, featuring a 133 MHz processor, 240 KB configurable user memory, and embedded dual 10/100 Mbps Ethernet ports with a built-in switch. It supports up to 4096 I/O points across eight baseplates, making it essential for upgrades demanding high reliability, rapid boolean execution at 0.15 ms per 1K words, and native SRTP or Modbus TCP without extra hardware. In industrial automation applications prioritizing long-term stability and reduced wiring overhead, the GE Fanuc IC693CPU374-GS enables direct Ethernet integration, floating-point math for precise calculations, and web server capabilities for remote diagnostics—ideal when transitioning to networked architectures while preserving investments in existing I/O racks.

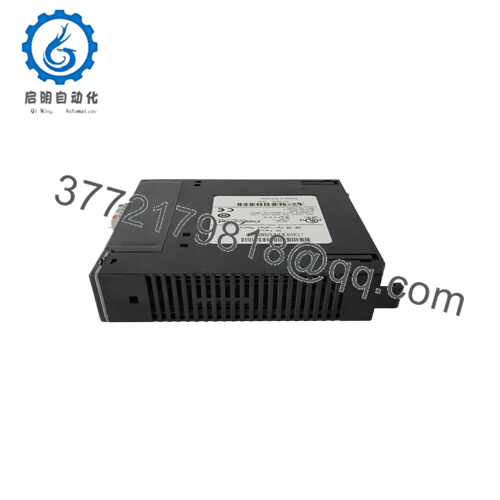

The GE Fanuc IC693CPU374-GS operates as the core processor in a Series 90-30 PLC, executing ladder logic, managing backplane I/O scans, and handling communications efficiently. It installs in the leftmost slot of the CPU baseplate, utilizing the high-speed parallel bus to interface with discrete, analog, and specialty modules across local or remote racks. In the automation stack, it processes time-critical control loops while its embedded Ethernet interface—two auto-sensing RJ-45 ports—connects directly to plant networks for SRTP client/server, Modbus TCP, or web access without additional modules. This eliminates the need for separate CMM321 Ethernet cards common in lower models, freeing slots and simplifying cabling. The power supply provides an RS-485 port for basic SNP programming, but the focus shifts to Ethernet for production data exchange with supervisory systems. Built-in diagnostics monitor faults, battery status, and network health via LEDs and fault tables, integrating into Proficy tools for proactive alerts. Supporting floating-point operations natively, it excels in applications needing calculations beyond basic boolean. Overall, the GE Fanuc IC693CPU374-GS modernizes the Series 90-30 platform by embedding robust networking at the controller level, ensuring deterministic performance in expanded, connected environments.

| Specification | Details |

|---|---|

| Model Number | GE Fanuc IC693CPU374-GS |

| Brand | GE Fanuc (Emerson) |

| Type | Single-Slot CPU Module with Embedded Ethernet (Series 90-30) |

| Input Voltage | 5 V DC (from backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Rack-mounted (single slot in baseplate) |

| Dimensions | Approx. 140 mm (H) x 55 mm (W) x 140 mm (D) |

| Weight | Approx. 0.45 kg |

| Interface/Bus | Series 90-30 backplane; dual 10/100 Mbps Ethernet (RJ-45) |

| Compliance | CE, UL, CSA, relevant EMC standards |

| Supported Protocols | SRTP, Modbus TCP, EGD; SNP via power supply RS-485 |

| Typical Power Draw | 7.4 W at 5 V DC |

- IC693CPU374-GS

- IC693CPU374-GS

Deploying the GE Fanuc IC693CPU374-GS provides exceptional processing consistency with its 133 MHz core, delivering fast scan rates that keep control loops responsive even in complex programs with data-intensive networking. Engineered for noisy industrial settings, it maintains stability across electrical interference and temperature fluctuations, minimizing unplanned interruptions.

The embedded Ethernet reduces engineering overhead significantly—no separate communication modules mean simpler configurations, fewer points of failure, and easier scaling when adding remote I/O or connecting to modern devices. Diagnostics and web access streamline maintenance, allowing quick status checks or firmware updates remotely.

In practice, the GE Fanuc IC693CPU374-GS ensures long-term performance in networked systems, protecting legacy investments while enabling contemporary features like real-time data sharing and enhanced visibility.

The GE Fanuc IC693CPU374-GS shines in discrete manufacturing, such as food and beverage lines coordinating high-speed packaging with networked oversight for traceability and continuous uptime. In pharmaceutical processing, it manages batch recipes and analog signals in regulated process control environments demanding precise timing and data integrity.

Water treatment facilities use it for distributed pump and valve control over Ethernet, supporting fast data cycles in harsh conditions while ensuring critical system uptime. Across these industries, the GE Fanuc IC693CPU374-GS offers reliable, high-speed connectivity in evolving automation setups.

GE Fanuc IC693CPU363 – Non-Ethernet predecessor for basic serial connectivity

GE Fanuc IC693CPU364 – Similar performance with additional serial ports

GE Fanuc IC693CPU360 – Lower-memory option without embedded networking

GE Fanuc IC693CPU350 – Entry-level CPU for smaller systems

GE Fanuc IC695CPU315 – RX3i series upgrade for next-generation performance

GE Fanuc IC693CMM321 – Standalone Ethernet module for non-embedded CPUs

GE Fanuc IC693PCM300 – Programmable coprocessor for specialized tasks

Before installing the GE Fanuc IC693CPU374-GS, ensure your baseplate power supply supports the higher current draw and has stable 5V output, particularly with loaded racks. Verify network settings compatibility and reserve IP addresses to avoid conflicts during Ethernet integration. Check firmware revision against your Proficy Machine Edition version for full feature support, and plan cabinet airflow given the module’s heat under network-intensive operation.

Maintenance typically involves monitoring front-panel LEDs for run status, faults, and Ethernet link/activity—quick during routine inspections. Replace the backup battery every few years or upon low indication to protect program memory. Periodically inspect RJ-45 connectors for secure seating in vibrating environments, and perform software-based network diagnostics to confirm link integrity without downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626