Description

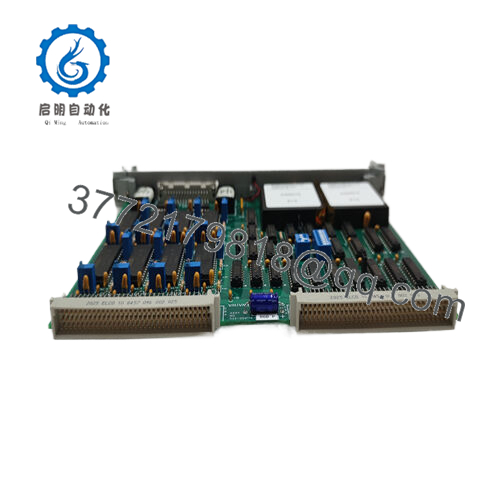

In extrusion plants where barrel heaters fight material inconsistencies during high-volume runs, or in injection molding cells synchronizing nozzle bands against cycle times, the GE HE693THM889 provides precise RTD temperature monitoring that stabilizes processes prone to thermal drift. Mold makers in automotive presses depend on its multi-channel accuracy to profile cavity temps, averting warps that scrap costly parts, while kiln operators in ceramics track zone gradients to hit firing specs without cracks. Rolled out in industrial automation for plastics, glass annealing, and heat treat ovens, this PACSystems Rx7i module confronts the variability of multi-zone heating—delivering linearization and fault detection across eight RTD inputs that feed PID loops, ensuring uniform melts or cures amid ambient swings.

Visualize a blow-molding line tweaking parison walls: the GE HE693THM889 polls PT100 sensors at 4 Hz rates, breaking averages to spot die imbalances before bottle rejects pile up. In semiconductor diffusion furnaces, it isolates thermocouple-like excursions via open-wire diagnostics, safeguarding wafer yields. Engineered for control systems in humid foundries or vibration-heavy forges, this high-resolution analog module supports 3-wire compensation, turning noisy field signals into rock-steady process variables that sharpen closed-loop performance. Integrators choose the GE HE693THM889 for rack-mounted setups demanding density without diagnostic downtime, converting raw thermal chaos into repeatable quality.

Product Role

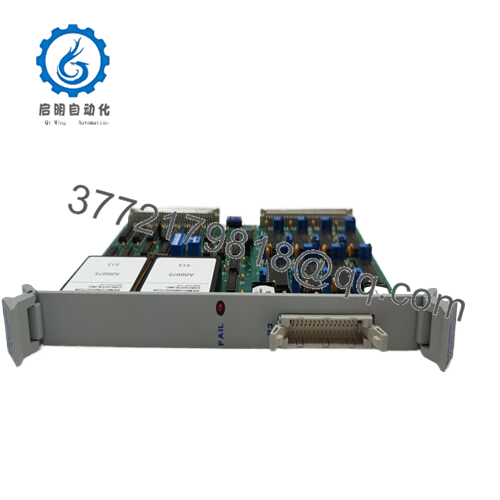

The GE HE693THM889 acts as an 8-channel RTD input module in GE’s PACSystems Rx7i series, plugging into universal backplanes to digitize resistance signals for precise temperature control in PLC architectures. Paired with VersaMax CPUs or Rx7i controllers via Proficy Logic Developer, it handles PT100/PT1000, Ni120, and copper probes with NIST-traceable scaling, fitting as the thermal backbone in SCADA hierarchies. It communicates over dual-port memory for redundancy, enabling hot-backup swaps in critical loops.

System architects value the GE HE693THM889 for oversampling noisy environments—up to 16-bit resolution per channel—while its per-point alarming cuts false trips from lead breaks. In distributed nodes, it expands via GBC carriers, prized for marrying legacy PAC I/O to Ethernet/IP trunks. This module’s burn-out detection and averaging filters streamline tuning, making it a staple where thermal uniformity dictates margins. The GE HE693THM889 embeds seamlessly, elevating raw sensing to enterprise insights.

Core Strengths

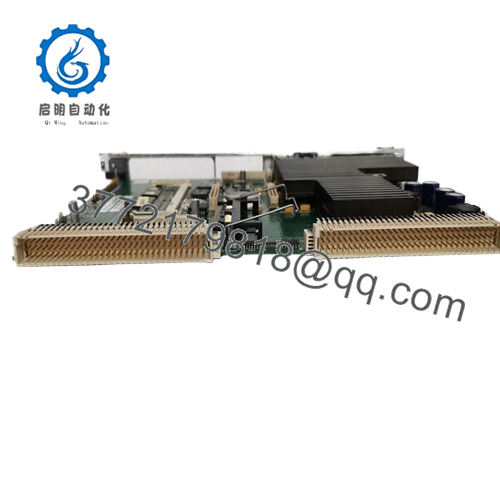

Process techs in fiber draw towers trust the GE HE693THM889‘s 0.1°C resolution across -200 to 850°C spans, with 3-wire rejection holding ±0.2% accuracy even through 100m cable runs laced with EMI. Eight isolated channels scan sequentially at 250 ms cycles, supporting universal RTD types sans jumpers, while configurable filters (10-200 Hz) tame furnace turbulence without phase lag. Backplane power draws 400 mA at 5V, with field excitation from integrated 2 mA sources— no external bridges needed—fusing outputs at 0.5A groups.

Rugged from the ground up, the GE HE693THM889 rates -40 to 70°C ops with 95% humidity tolerance, shrugging 30G shocks and 5G/5-2000 Hz vibes that rattle lesser cards. Optical isolation hits 1500Vrms channel-to-logic, buffering PLC cores from ground loops in multi-drive bays. Status LEDs per input glow open/fault/under-range at arm’s length, and diagnostic bits flag excursions pre-alarm. The GE HE693THM889 boasts 2M-hour MTBF via conformal coating, outpacing electromechanical rivals.

Field-proofing includes reverse-voltage clamps and self-calibration on boot, yielding drift-free baselines over years. Hot-insert capability preserves rack power, with EEPROM configs auto-loading to slash recommissioning. For thermal arrays demanding unwavering fidelity, this module delivers.

- HE693THM889

Specifications

| Parameter | Value |

|---|---|

| Model | HE693THM889 |

| Brand | GE Fanuc (PACSystems Rx7i) |

| Type | 8-Channel RTD Input Module |

| Power Supply | 5 VDC backplane (400 mA max) |

| Operating Temperature | -40 to 70°C |

| Storage Temperature | -40 to 85°C |

| Mounting | Rx7i rack backplane |

| Dimensions | 140 x 34 x 140 mm |

| Weight | 0.25 kg (0.55 lbs) |

| Interfaces | 3-wire RTD terminals (24 pts) |

| Input Types | PT100/1000, Ni120, Cu10 |

| Resolution | 16-bit (0.1°C typical) |

| Certifications | CE, UL, CSA Class I Div 2 |

| Isolation | 1500 Vrms field-to-backplane |

| Environmental Rating | IP20, conformal coated |

| Scan Rate | 250 ms all channels |

Compatible Units

HE693RTM889 – Thermocouple companion for hybrid high-temp profiling.

IC200ALG230 – Analog output mate closing PID thermal loops.

HE693PBM001 – Profibus master linking to remote sensor nets.

IC200MDD844H – Discrete mixer for heater contactor staging.

HE697RTM001 – High-density RTD expander for 32-point ovens.

IC200UCP001 – VersaMax CPU host for compact thermal nodes.

HE693SPC001 – Power supply ensuring stable excitation rails.

Installation Tips

Seat the GE HE693THM889 into live racks with extractor tabs aligned—firm push till LEDs blink OK—then ferrule 20-16 AWG shields into 24-position Euroblock, twisting pairs tight for 3-wire balance and torquing to 0.5 Nm. Source 24VDC auxiliaries isolated from logic grounds, adding MOVs across long sensor runs over 50m; pre-twist leads 1 turn/inch to quash noise. Ventilate slots with 25 mm gaps in dense packs, bonding chassis via M4 PEMs at 1 Nm—label alpha tags pre-flash.

Monthly scans via Proficy reveal drift thresholds; toggle cal verifies linearity sans probe pulls. Trim pots absent—software scales handle NIST curves—but annual oven tests with master RTDs log offsets. EEPROM backups sidestep field laptops, while open-wire sims catch intermittents early. These routines anchor the GE HE693THM889‘s thermal precision.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626