Description

What This Product Solves

In legacy GE Speedtronic Mark I and Mark II turbine control systems, the single most frustrating cause of forced outages and start refusals is often a failed thermocouple input card. When flame detectors, exhaust thermocouples, bearing metal sensors, or wheelspace temperature probes lose reliable monitoring, the protection logic immediately trips the unit—even if the hardware itself is fine—because the controller can no longer trust the temperature data. The GE IC3600ALTC1 exists specifically to eliminate that vulnerability in plants that must keep Mark I/II platforms running for years or decades longer.

This 16-channel Type K thermocouple input module with integrated cold-junction compensation gives you clean, linearized, 12-bit temperature readings across the exact ranges the original turbine sequencing and protection logic expects. Plants running Frame 5, Frame 6, Frame 7B/E, or LM series engines routinely see these cards become mission-critical during peak demand seasons when an unplanned trip can cost millions. The GE IC3600ALTC1 becomes the go-to replacement when original cards are no longer repairable, when cold-solder cracks cause intermittent open-circuit faults, or when you simply refuse to gamble on thirty-five-year-old electrolytic capacitors in a protective monitoring chain. For industrial automation and process control environments that demand continuous uptime from proven 1970s-era technology, the GE IC3600ALTC1 restores high-reliability thermocouple signal acquisition without forcing a risky controls migration.

How the Product Works & Fits into a System

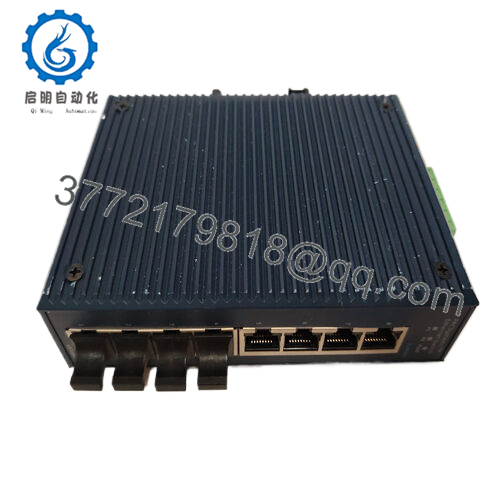

The GE IC3600ALTC1 is a direct plug-in thermocouple input board for the classic Speedtronic Mark I and Mark II card racks. It occupies one slot alongside the CPU, power supplies, and other I/O cards, connecting through the same parallel backplane bus architecture that GE standardized in the 1970s. Each of the 16 channels accepts grounded or ungrounded Type K (chromel-alumel) thermocouples directly; no external signal conditioners or transmitters are required.

On-board cold-junction compensation uses a precision temperature sensor mounted at the terminal block, ensuring the card automatically corrects for ambient variation at the panel terminals. Linearization is performed in hardware via function-generation networks, so the Speedtronic logic receives temperature values already scaled in degrees Fahrenheit exactly as the original elementary diagrams specify. Open-thermocouple detection is built in: if a wire breaks or a sensor fails open, the channel drives upscale to +4095 counts, instantly triggering the configured alarm or trip without ambiguous readings.

Status is reported through the familiar card-edge LEDs and the system’s existing fault word structure, so operators see thermocouple health the same way they always have. Because the GE IC3600ALTC1 preserves identical pinout, scaling, and response time, you can swap it in during a minor or major outage with zero changes to ladder logic, trip setpoints, or HMI displays.

- IC3600ALTC1

- IC3600ALTC1

| Specification | Details |

|---|---|

| Model Number | IC3600ALTC1 |

| Brand | GE (General Electric) |

| Type | 16-Channel Type K Thermocouple Input Module |

| Input Voltage | Type K thermocouple (direct mV) |

| Operating Temp Range | 0 °C to 60 °C (panel ambient) |

| Mounting Style | Speedtronic Mark I/II card rack |

| Dimensions | 12.3″ × 8.6″ (standard double-width card) |

| Weight | ≈ 1.1 kg |

| Interface/Bus | Parallel Speedtronic I/O bus |

| Compliance | Original GE industrial standards |

| Supported Protocols | Native Mark I/II ladder logic |

| Typical Power Draw | 10 W from rack supply |

Real-World Benefits

Deploying a new GE IC3600ALTC1 removes the nagging uncertainty that comes with running forty-year-old thermocouple cards patched together through multiple repairs. Modern multilayer boards, laser-trimmed resistors, and high-stability CJC sensors deliver accuracy that actually exceeds many of the original production units after decades of drift. Exhaust temperature spread monitoring stays tight, flame detector reliability returns to specification, and bearing or lube-oil temperature trips stop happening because of noisy or drifting inputs.

Maintenance teams regain confidence: open-circuit detection works every single time, and the upscale drive behavior is guaranteed, so you never again see a “ghost” low-temperature reading that masks a real burner problem. Calibration is rarely needed—most plants simply verify zero and span against a Type K calibrator once after installation and then trust the card for the next decade. By choosing the GE IC3600ALTC1, you effectively buy ten to fifteen more years of proven protective monitoring while eliminating one of the highest-risk failure points in the entire control system.

Typical Use Cases

The GE IC3600ALTC1 is the standard thermocouple input module in nearly every heavy-duty gas turbine still operating on Mark I or Mark II controls. Combined-cycle and simple-cycle power plants use multiple cards for exhaust thermocouple arrays (typically 12–27 probes), wheelspace temperature protection, and flame scanner intensity cross-checking. Pipeline compressor stations running LM2500, LM5000, or older Frame engines depend on it for bearing metal and lube-oil temperature monitoring under 8760-hour continuous duty.

Marine propulsion packages on LM2500-powered naval and commercial vessels rely on the card for the same critical temperature loops in high-vibration, salt-laden environments. Anywhere turbine safety and availability regulations require that protective functions remain unchanged during life-extension projects, the GE IC3600ALTC1 provides the only practical path forward.

Compatible or Alternative Products

IC3600ALTA1 – Earlier single-width version with same functionality

IC3600ALTX1 – Extended-range version for J and E thermocouples

IC3600ADAF1 – General-purpose mV input card sometimes used as substitute

IC3600ALTD1 – 8-channel lower-density thermocouple card

IC3600QOXB – Analog output card frequently paired for temperature control

IC3600SFTD1 – Dedicated flame-scanner interface often installed in same rack

IC3600AVIA1 – Vibration input module commonly used alongside for complete monitoring

Setup Notes & Maintenance Insights

Before installation, confirm your rack has the later-style terminal blocks with the integrated CJC sensor landing; early Mark I racks sometimes need a small wiring update to bring the compensation signal onto the correct pins. Set the two configuration jumpers for grounded versus ungrounded thermocouples exactly as the failed card was configured—most plants run grounded for noise immunity. Ensure at least one empty slot adjacent for convection cooling; thermocouple cards run slightly warmer than digital boards.

After insertion, execute the standard thermocouple confidence test (most sites have a pushbutton or elementary that injects a known mV offset). All 16 channels should read within ±2 °F of the calibrator across 500 °F and 1200 °F setpoints. Ongoing maintenance is minimal: during major outages, inspect the terminal screws for looseness and verify the CJC sensor hasn’t been painted over. A quick open-circuit test on one spare channel every few years confirms upscale drive is still functioning. Drift is typically under 1 °C over ten years.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626