Description

1. Real-world use & applications

In real plants, the GE IC3600TPSA1D sits deep inside the turbine control cabinet, supporting critical auxiliary power for cards that handle sequencing, protection, and monitoring of heavy-duty gas or steam turbines. Typical environments include power generation stations, industrial cogeneration units, and process plants where GE Speedtronic Mark I/II systems are still in service, often as part of older but well-maintained turbine trains. Operators rely on this board to keep low-voltage control electronics stable during start-up, loading, and transient conditions, when line disturbances and inrush currents can be severe.

Because Mark I/II systems predate modern distributed control systems, much of the control intelligence resides on individual printed circuit boards. A failed power supply board can bring down an entire control rack, forcing a turbine trip or preventing a restart. This is why many asset owners keep the GE IC3600TPSA1D in strategic spares programs and source refurbished or surplus units from the aftermarket. In life-extension projects, this board is often either replaced with like-for-like parts or evaluated during upgrade paths to newer excitation or control platforms. Engineers searching for this model are typically troubleshooting loss of logic power, intermittent rack resets, or undervoltage alarms linked to the original GE Mark I/II hardware

2. Product introduction & positioning

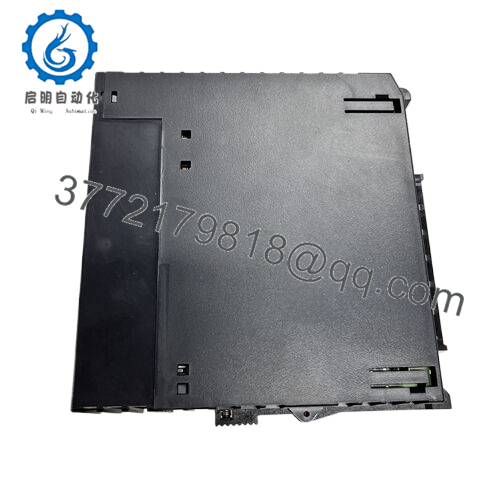

Functionally, the GE IC3600TPSA1D is best described as a single-phase power supply / drive board within the GE Fanuc / General Electric turbine control hardware family. It accepts an AC input (typically from a dedicated control power transformer) and produces the DC supply rails used by other Mark I/II control cards, often including reference voltages and logic-level supplies. The board plugs into the IC3600-style card rack characteristic of early Speedtronic systems, using edge connectors for both power and signal interfacing.

Within the architecture, this board underpins the reliability of all higher-level control functions. Sequence logic, protective relays, and analog interface boards depend on the regulated outputs from the GE IC3600TPSA1D, so its stability directly affects trip logic and turbine availability. From a lifecycle perspective, it is a “hidden” but mission-critical component: not visible in HMI software, yet essential for safe and repeatable starts. The board is normally used as a direct replacement part rather than a configurable module, and it is specified by exact model string (including the “1D” revision suffix) to ensure compatibility with the original panel wiring and rack hardware

For engineers and maintenance planners, the GE IC3600TPSA1D represents a pragmatic way to keep legacy turbines online without undertaking an immediate full controls retrofit. It fits directly into existing Mark I/II panels, avoids major rewiring, and is usually available via surplus or specialized legacy-parts suppliers familiar with GE turbine controls.

- IC3600TPSA1D

3. Key technical features & benefits

One of the main strengths of the GE IC3600TPSA1D is its purpose-built design for the electrical environment of Mark I/II turbine controls. While detailed parameters vary by revision, it is engineered as a single-phase power supply board capable of delivering stable DC under fluctuating grid or auxiliary bus conditions that occur during turbine startup and load changes. This robustness is essential for avoiding nuisance trips caused by momentary voltage dips or inrush associated with contactors and auxiliary drives.

The board is built on a rugged through‑hole PCB technology typical of its era, with discrete components, transformers, rectifiers, and regulators laid out for serviceability and thermal robustness. This makes the GE IC3600TPSA1D relatively repairable by qualified shops who specialize in legacy GE boards, extending the life of installed assets when OEM lead times are long or direct manufacture has ceased. Its mechanical form factor is compatible with the standard IC3600 rack, enabling quick swap-out during outages with minimal disturbance to adjacent cards and wiring.

Compatibility is another key benefit. The GE IC3600TPSA1D belongs to the same family of IC3600-series boards used across Mark I/II systems, so its electrical interface and pinout are designed to work seamlessly with other GE Fanuc control and drive boards in those racks. This means that as long as the correct part number and revision are chosen, no configuration changes are typically required—engineers can focus on functional testing and verification after replacement.

In terms of long‑term reliability, the board’s design emphasizes conservative component ratings and transformer‑isolated supplies, which historically contributed to the long service lives of Speedtronic systems. Many units now in the aftermarket are refurbished or tested, and asset owners commonly send failed GE IC3600TPSA1D boards to specialist repair centers for reconditioning, capacitor replacement, and burn‑in testing to re-establish confidence before reinstalling in a running turbine.

4. Detailed technical specifications

| Parameter | Value (typical / contextual) |

|---|---|

| Model | GE IC3600TPSA1D |

| Brand | General Electric / GE Fanuc |

| Product type | Single‑phase power supply / drive circuit board |

| System family | GE Speedtronic Mark I / Mark II turbine control racks |

| Input type | Single‑phase AC control power (from dedicated transformer) |

| Output function | Provides regulated DC power for control and logic boards |

| Mounting | Plug‑in IC3600 rack-mount PCB with edge connector |

| Typical application | Gas / steam turbine control power in legacy Speedtronic systems |

| Construction | Through‑hole PCB with discrete components and transformer sections |

| Associated equipment | Other IC3600 control, protection, and interface boards |

| Typical condition on market | New surplus or refurbished “UNMP” / used tested units |

| Revision code | Suffix “1D” indicates specific hardware revision within TPSA series |

5. Related or compatible units

IC3600TPSA1H1 – Alternative revision of the same TPSA power supply board family, used in similar Mark I/II applications; often considered when exact “1D” units are unavailable and engineering accepts revision changes

IC3600TPSA1G1B – Closely related power supply version used in comparable turbine control racks; typically interchangeable only after checking site documentation.

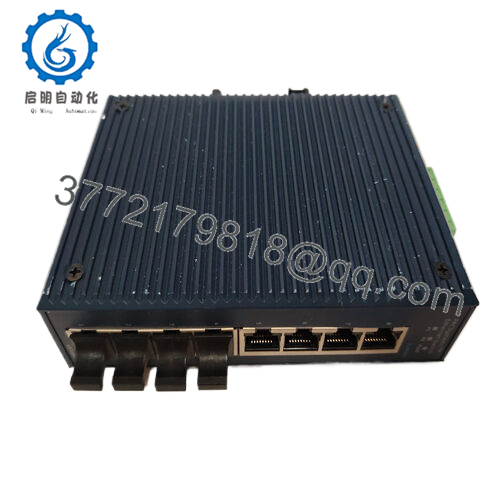

IC3600AIAE1A1B – A current sensor board from the same IC3600 series, indicating the broader family of control and measurement PCBs used alongside the GE IC3600TPSA1D.

IC3600DLCA1B – Another GE IC3600 circuit board type, showing how power, logic, and interface cards work together in the same rack environment.imimg

IC3600TPSA1 – Base part-number designation for the TPSA single‑phase power supply series, with suffix letters denoting specific revisions such as the GE IC3600TPSA1D.

6. Installation notes & maintenance best practices

When replacing or installing a GE IC3600TPSA1D, technicians should first confirm that the rack is fully de‑energized and that turbine start permissives are locked out. The card edge connector and mating socket need to be inspected for discoloration, bent contacts, or evidence of overheating before the new board is inserted. Alignment with the guide rails of the IC3600 rack is important; forcing the board can damage both PCB and backplane. It is also good practice to verify that incoming control power transformers and protective devices feeding the board match the original design values recorded in the turbine control drawings.axcontrol+1

From a maintenance perspective, legacy power supply boards benefit from periodic visual inspection during planned outages. Signs such as bulging electrolytic capacitors, heat‑stressed resistors, or carbonization near high‑power components are early indicators that the GE IC3600TPSA1D may need proactive refurbishment. Many operators adopt a rotate-and-repair strategy: install a spare tested board, then send the removed board to a specialist for overhaul and bench testing. Recording serial numbers, revision codes, and installation dates helps track recurring issues and supports long‑term fleet reliability planning. Because Mark I/II systems are aging, coordination with experienced repair houses or upgrade consultants is increasingly valuable for assessing when repeated board failures justify a broader controls retrofit.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626