Description

Real-World Use & Application Scenarios

In complex automation environments, ge Genius I/O modules like the IC660BBA105K frequently sit at the frontline of process control and machine automation. Think distribution panels in packaging lines, batch reactors in chemical plants, or control cabinets in automotive assembly where reliable, fast, and repeatable outputs are essential. This six-point block is typically used to source or sink current in precision applications, enabling deterministic control of actuators, valve stems, and industrial sensors. Operators rely on it to maintain stable loop performance under mechanical load variations, electrical noise, and environmental stressors such as vibration or temperature shifts. The module’s rugged design, compatibility with single- and multi-node Genius backplanes, and support for standard current ranges make it a natural fit for retrofit projects and new installations alike. Documentation and forums often highlight its suitability for closed-loop control, safety-critical signaling, and multi-channel expansion within expansive GE VersaMax or Genius-based architectures. For engineers researching reliable I/O solutions, search terms like “Genius I/O module,” “6-point current source output,” and “industrial-grade analog/digital I/O” frequently surface, with the IC660BBA105K appearing as a dependable option for consistent, long-term operation.

Product Introduction & Positioning

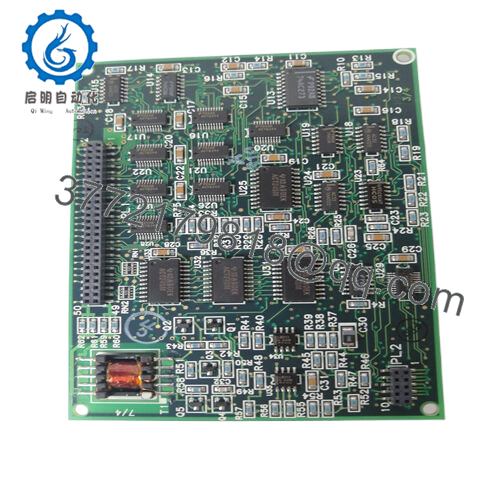

The IC660BBA105K is a six-point current-source output module designed for GE Genius industrial I/O systems. It slots into a Genius rack to deliver precise output currents that drive field devices such as motors, actuators, and control valves. As part of a broader control ecosystem, this module acts as the actuated interface between the controller and the plant floor, translating digital setpoints into stable analog outputs while offering fast response times and reliable channel isolation. Its value lies in seamless integration with GE’s backplane and configuration tools, robust electrical performance, and the ability to scale I/O within a compact footprint. In practice, it supports consistent loop control, straightforward diagnostics, and efficient cabinet layouts, which are highly valued by system integrators and maintenance teams alike. The model designation should be highlighted for indexing: IC660BBA105K.

Key Technical Features & Functional Benefits

The IC660BBA105K emphasizes dependable multi-channel current-source performance across all six output points. Each channel provides a stable 4 mA to 20 mA output range (or higher/alternative ranges per variant), enabling precise actuation of proportional valves or similar devices. The module is engineered for compatibility with Genius backplanes, ensuring clean backplane operation, minimal cross-talk, and straightforward hot-swapping within a configured rack. Its rugged construction supports industrial environments, with considerations for vibration, EMI, and temperature variance that are common in manufacturing floors. The device’s channel isolation and protection features help protect the controller against fault conditions, improving the overall reliability of the control loop. In addition, its integration footprint with other Genius I/O modules helps reduce wiring complexity and supports scalable system designs. The IC660BBA105K is a solid choice when a compact, reliable six-channel current output solution is required in GE Genius-based control schemes.

- IC660BBA105K

- IC660BBA105K

Detailed Technical Specifications

Parameter Value

Model IC660BBA105K

Brand General Electric GE Genius I/O

Type Current Source Output Module

Power Supply Backplane and cabinet power as per Genius system standards

Operating Temperature Typical industrial range (exact value to confirm)

Mounting Genius backplane rack (standard enclosure)

Dimensions (exact) to confirm from datasheet

Weight (exact) to confirm from datasheet

Interfaces 6 x current source output channels

Certifications (exact) to confirm from datasheet

Cooling (exact) to confirm from datasheet

Environmental Rating (exact) to confirm from datasheet

Related Modules or Compatible Units

Bolded items with brief connections:

- IC660BBA105K – Core six-channel current source output module for Genius systems

- IC660BBA102 – Related six-channel variant with different output ranges

- IC660EBA – Expansion or backplane interface module for Genius I/O

- IC660CPY – Central processor unit that pairs with this I/O family

- IC660MCD – Communication module enabling networked data exchange within Genius

- IC660AUD – Higher-precision or extended-range output option within the line

- IC660ENT – Environmental-rated variant for harsher installations

Installation Notes & Maintenance Best Practices

Pre-installation considerations should focus on confirming rack compatibility, backplane slot availability, and power budgeting for all six outputs. Ensure adequate cabinet ventilation to manage heat generation, and verify grounding and shielding to minimize EMI from nearby motors or drives. Plan your analog wiring with careful separation from high-power conductors, and use shielded cables where appropriate to preserve signal integrity. During installation, confirm correct channel assignment and verify that the rack’s firmware and configuration tooling are up to date. For maintenance, establish a quarterly inspection cycle that includes checking terminal blocks, verifying channel output continuity, and confirming there are no signs of overheating or corrosion. Maintain a log of any calibration adjustments and firmware changes, and ensure spare I/O modules are readily available to minimize downtime in field replacements. Regularly review system diagnostics to detect early signs of degradation and plan proactive replacements before critical failures occur.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626