Description

In many process control and industrial automation environments, accurate temperature measurement using RTDs is non-negotiable, yet the practical challenges of running long three- or four-wire sensor cables through electrically noisy plants frequently introduce resistance errors, lead compensation headaches, and intermittent faults that show up as mysterious drifts or alarm storms. When you have dozens of bearing temperatures, motor windings, or reactor jacket points that must stay within a degree or two for safe continuous operation, the cost of false trips or undetected overheating quickly outweighs any savings from cheap centralized I/O. Traditional home-run wiring to a PLC rack becomes a maintenance nightmare, while remote smart transmitters add unnecessary expense and complexity when all you really need is clean, linearized resistance-based data delivered reliably to the controller.

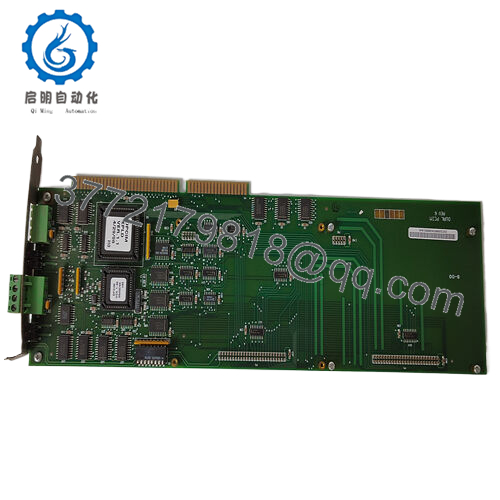

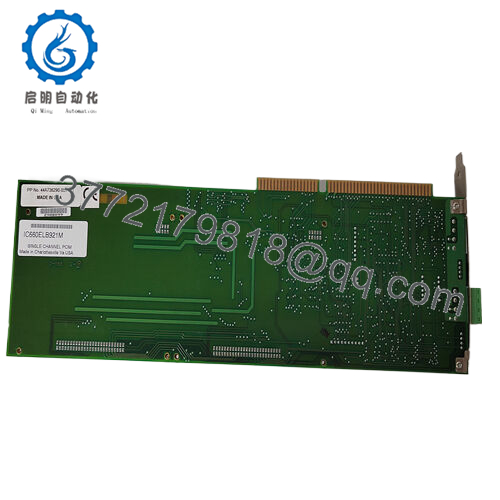

The GE IC660EBA101 solves this exact problem as a 16-channel RTD input block in the proven Genius I/O family. By placing high-accuracy RTD measurement right where the sensors are—often directly on a turbine skid, compressor deck, or furnace wall—the GE IC660EBA101 eliminates most lead-length errors before they happen, performs individual three- and four-wire compensation on every channel, and sends fully scaled engineering-unit data over a single noise-immune Genius bus drop. Plants that once spent outages chasing ground loops or recalibrating remote terminal panels now enjoy rock-solid temperature trending and far fewer spurious alarms. It’s the kind of high-reliability RTD solution that has kept critical rotating equipment and heat-exchanger monitoring systems online for decades in some of the toughest industrial settings.

The GE IC660EBA101 operates as an intelligent distributed node on the Genius I/O bus—the same deterministic, token-passing network that has been carrying I/O data in power plants and refineries since the late 1980s. Each channel independently excites its RTD with a precision current source, measures the return voltage, compensates for lead resistance, linearizes to temperature using IEC751 or DIN curves, and applies user-selected fault thresholds before placing the result on the bus. A Series 90-30, 90-70, Rx3i PAC, or third-party host with a Genius interface simply reads pre-scaled °C or °F values—no scaling blocks, no compensation math, no custom function blocks required.

Built-in diagnostics go well beyond simple open-wire detection: the block reports over-range, under-range, lead-break, and excitation faults on a per-channel basis, and it continuously monitors its own internal reference for drift. Dual-bus cable capability and hot-insertion support mean you can achieve true redundancy or replace a block online without dropping the rest of the network. Scan times remain fast—typically under 10 ms for an entire bus segment—so the GE IC660EBA101 fits seamlessly into tight cascade or protective interlock loops where even a 100 ms delay matters.

- IC660EBA101

| Specification | Details |

|---|---|

| Model Number | GE IC660EBA101 |

| Brand | GE (now Emerson) |

| Type | 16-Channel RTD Input Block |

| Input Voltage | 24 VDC (18–56 VDC range) |

| Operating Temp Range | 0 °C to 60 °C |

| Mounting Style | Panel mount or DIN-rail adapter |

| Dimensions | 8.83″ × 3.56″ × 4.42″ (224 × 90 × 112 mm) |

| Weight | 4 lb (1.8 kg) |

| Interface/Bus | Genius I/O (dual terminal or RJ-45) |

| Compliance | CE, UL, CSA, Class I Div 2 |

| Supported Protocols | Genius proprietary (89.3 kbaud) |

| Typical Power Draw | 9 W |

Engineers who specify the GE IC660EBA101 quickly realize they’ve removed an entire class of chronic measurement problems. Three- and four-wire compensation is performed individually on every channel, so mixing sensor lead lengths on the same block is never an issue. Channel-to-channel isolation of 250 VAC continuous stops ground loops dead, while the precision current sources and 16-bit conversion deliver better than 0.1 °C resolution across the full Pt100 range. Because there are no multiplexers or relays in the signal path, long-term stability is exceptional—many blocks still hold factory calibration accuracy after twenty years in service.

From a maintenance perspective, the value is even clearer. Fault isolation down to the exact channel means technicians spend minutes instead of hours tracing problems. Configuration is stored both in the block and downloadable from the bus controller, so field replacements are truly plug-and-play. The net result is significantly lower total cost of ownership than either centralized analog cards with massive home-run cabling or fleets of single-loop smart transmitters.

You’ll find the GE IC660EBA101 protecting turbomachinery in power plants and refineries—monitoring bearing metal, lube-oil, and stator winding temperatures where a single degree can be the difference between planned maintenance and a forced outage. Large compressor stations along natural-gas pipelines rely on it for anti-surge control and mechanical protection systems. Metals processing—steel, aluminum, and glass—uses dense RTD blocks around induction furnaces and cooling beds where vibration, heat, and electrical noise are constant companions. In every case the requirements are identical: high channel density, sub-degree accuracy, and proven survival in Class I Div 2 areas with zero tolerance for unscheduled downtime.

GE IC660EBA021 – Earlier revision with identical RTD performance, still widely installed

GE IC660EBA023 – Mixed thermocouple/RTD block for skids that have both sensor types

GE IC660EBA020 – Thermocouple companion block when high-temperature points exceed RTD limits

GE IC660EBA106 – 6-channel high-accuracy RTD version with individual CJC for lab-grade needs

GE IC660BBA101 – 16-channel 24/48 VDC analog current input for 4–20 mA transmitters

GE IC660BBD101 – Matching 16-channel digital input block for vibration or proximity switches

GE IC660BBR101 – Genius redundancy link module for dual-cable fault-tolerant operation

Before installation, make sure 24 VDC field power is present and sized for roughly 9 W plus any downstream blocks on the same feed. Leave the standard 2-inch top and bottom clearance for cooling—Genius blocks are convection cooled and run warm under full load. Double-check that your bus is properly terminated (75 Ω at each end) and that the host CPU or bus interface module is running firmware that supports RTD linearization tables—virtually all Rx3i and late-model 90-70 CPUs do.

Routine maintenance is straightforward: walkdown LED checks (steady green = good, flashing patterns instantly identify open leads or excitation faults), and an annual power-cycle with diagnostic report review confirms reference stability. Spring-cage terminals hold up extremely well; a gentle tug test every few years is usually sufficient. If a block ever needs swapping, the new unit pulls its entire channel configuration from the bus controller automatically—no handheld programmer required in most modern systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626