Description

The GE IC687BEM713C is typically deployed where a single programmable controller must reliably extend its reach across multiple remote racks, long production lines, or distributed machine cells without sacrificing determinism or diagnostic visibility. In real plants, this often means packaging lines with several conveyor sections, batch processing systems spread over multiple floors, or material handling systems where drives, valves, and sensors sit tens of meters away from the main CPU rack. Engineers choose the GE IC687BEM713C when they need to expand an existing GE Fanuc or legacy GE PLC platform while maintaining strict timing for interlocks, permissives, and coordinated start/stop sequences used in industrial automation. The module helps tie together remote I/O racks used in control systems for sectors like food and beverage, specialty chemicals, automotive component assembly, and water treatment, where downtime penalties are high and field wiring density is significant

In these environments, control cabinets may be distributed around a plant, each with its own I/O rack, yet all must behave as part of one coherent control system. The GE IC687BEM713C acts as the communication bridge for that rack expansion, allowing high‑speed data exchange between a central controller and multiple expansion racks with minimal latency. This is especially valuable when engineers are pushing more analog channels, high‑speed digital signaling, or motion‑related I/O closer to the equipment, but still want all logic executed centrally for easier change management. Because it is used in industrial automation networks rather than field instrumentation directly, the module is commonly installed in protected control panels, but it must still tolerate electrical noise, temperature variation, and long cable runs typical of large manufacturing sites. For system integrators, the ability of the GE IC687BEM713C to support multiple racks over a shared bus makes it a practical choice when modernizing older GE‑based lines without fully redesigning the architecture

Product introduction and role

The GE IC687BEM713C is a bus expansion or bus transmitter module designed for GE and GE Fanuc programmable controller systems, where it provides the backbone link between a main rack and one or more remote or expansion racks. Functionally, it operates as an input/output communication interface, moving process data and status information between the CPU and the distributed I/O baseplates. Within a typical control system, the GE IC687BEM713C occupies a slot in the primary rack and connects via dedicated expansion cabling to downstream racks, effectively extending the backplane over distance while preserving the addressing structure that engineers expect

This positioning makes the GE IC687BEM713C particularly valuable in brownfield upgrades or incremental expansions of GE‑based control platforms, where there is a strong desire to reuse proven I/O hardware yet expand capacity or relocate equipment. Instead of moving the main controller or adding an entirely separate PLC, integrators can use this module to add remote I/O while keeping a unified project in the programming software and a single point of logic execution. For plant engineers, the GE IC687BEM713C offers a balance of high‑speed data transfer, deterministic behavior, and straightforward configuration aligned with the established GE Fanuc ecosystem, so crews familiar with legacy hardware can maintain and troubleshoot it without a steep learning curve. Its role in the architecture is therefore both structural and strategic: it keeps the control system scalable while protecting prior investments in GE infrastructure.

Key technical features and benefits

The GE IC687BEM713C is built around a high‑speed backplane extension design, typically supporting data rates on the order of hundreds of kilobytes per second, which is sufficient for large I/O images and frequent status updates across multiple remote racks. This performance level helps ensure that even with several expansion bases online, interlocks, alarms, and sequence commands remain tightly synchronized, which is critical for coordinated motion, safety interlocks, and complex batch steps used in industrial automation. Engineers benefit from deterministic data transfer; input changes and output commands propagate predictably, which simplifies tuning of scan times and reduces the risk of race conditions in distributed control logic

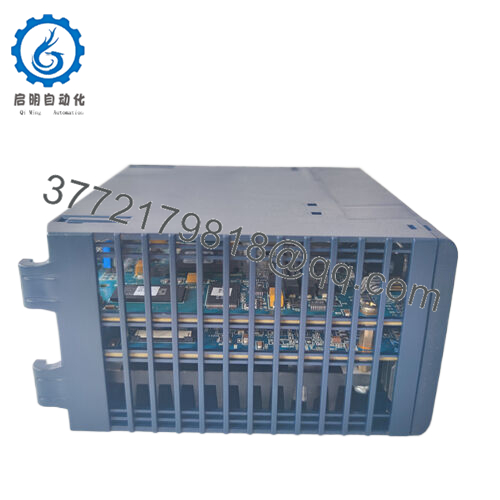

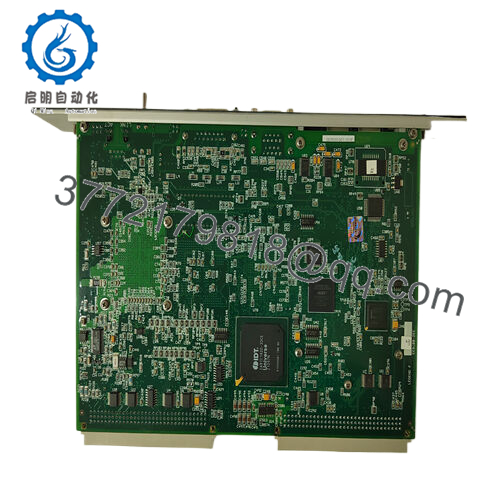

From a hardware standpoint, the GE IC687BEM713C typically uses a half‑slot or compact form factor suitable for standard GE racks, minimizing space impact in already crowded panels. Its front‑panel connectors and indicators are arranged to support quick visual status checks, so technicians can rapidly confirm bus health, communication activity, and fault conditions without opening a laptop. The module is designed for operation in common industrial control cabinet conditions, often in the 0 °C to 60 °C range, which aligns with many PLC and I/O products used in climate‑controlled or mildly conditioned MCC and PLC rooms. This environmental capability, combined with robust electrical design, contributes to long service life in applications where equipment is expected to run continuously for years.

Compatibility is a core strength of the GE IC687BEM713C, as it is intended to integrate smoothly with relevant GE / GE Fanuc CPUs and I/O families, allowing shared configuration tools and consistent addressing models. This reduces engineering time during design and commissioning, since expansion racks appear in the project as logical extensions of the main system rather than as separate, loosely coupled subsystems. Long‑term, that same compatibility helps maintenance teams manage spares, documentation, and training around a single vendor ecosystem, simplifying lifecycle management. Reliability is further supported by mature firmware and proven bus signaling methods that have seen extensive use in industrial control systems, giving owners confidence that the GE IC687BEM713C will remain stable under normal electromagnetic noise and loading conditions.

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | GE IC687BEM713C |

| Brand | General Electric (GE Fanuc) |

| Product Type | Bus expansion / transmitter I/O communication module |

| System Compatibility | GE / GE Fanuc PLC racks and associated I/O bases |

| Data Transfer Rate | Typically up to 500 kilobytes per second |

| Expansion Capacity | Supports multiple downstream racks (up to several expansion bases depending on system configuration) |

| Power Supply Requirement | Supplied from host rack backplane (standard GE rack power) |

| Operating Temperature Range | Approximately 0 °C to 60 °C (indoor control cabinet use) |

| Bus Interface Type | Rack backplane to remote rack expansion cabling (half‑slot style interface where applicable) |

| Mounting Method | Plug‑in rack module for GE PLC baseplate |

| Typical Cable Length | Short to medium range plant‑scale distances (on the order of tens of meters, depending on cable type and system rules) |

| Indicators | Front‑panel status LEDs for bus health and communication activity (implementation varies by revision) |

- IC687BEM713C

Related and compatible modules

IC687BEM713 – Earlier or alternate revision of the same bus expansion family, used where the C‑revision features are not required but similar functionality is needed.

IC687RCM711B – Related rack or communication module typically associated with GE remote rack schemes, often installed in companion racks within the same system.

IC697CMM742 – Communication module from the GE 90‑70 family that can coexist in systems using similar GE networking architectures for higher‑level communications.

IC697CPX928 – High‑end GE CPU used with large systems where the GE IC687BEM713C may provide distributed I/O expansion from the main rack.

IC600 or IC693 I/O modules – Typical discrete and analog I/O units that populate the expansion racks connected via the GE IC687BEM713C in mixed legacy environments.

IC687BEM731 – Alternative bus expansion module variant used in comparable applications when different performance or system constraints apply.

Installation notes and maintenance practices

When planning installation of the GE IC687BEM713C, engineers should first verify rack slot availability, cabinet depth, and clearance for the required expansion cabling within existing control panels. Proper panel layout should account for cable bend radii and segregation from high‑voltage power wiring to minimize electrical noise coupling on the bus lines. Grounding practices recommended for the host GE PLC system should be followed, including bonding of rack and panel grounds and correct shield termination for expansion cables where specified in the system manual. Because this module extends the backplane, it is important to adhere to the maximum number of supported expansion racks and cable length limits defined for the platform so that bus timing and signal integrity remain within specification.

Routine maintenance for the GE IC687BEM713C usually focuses on periodic visual inspections, checking for loose connectors, damaged cables, and any abnormal LED status indicating communication faults or bus errors. Plant technicians should include this module in scheduled cabinet cleaning activities, ensuring ventilation paths are not blocked and that ambient temperatures stay within the specified operating range to protect long‑term reliability. During shutdown windows, it is good practice to verify tight seating of the module in the rack and confirm that firmware and configuration remain aligned with the project backups kept in the maintenance system. In systems where diagnostics are available through the controller software, engineers can trend communication error counters or bus status bits associated with the GE IC687BEM713C to detect degrading conditions before they trigger downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626