Description

The GE IC687BEM731-AB is typically installed in control rooms or main PLC panels where a plant needs to tie multiple Genius remote I/O drops and field devices into a central GE control system. It sits in the rack alongside the CPU and other communication modules, managing all data exchange on the Genius bus to motor control centers, remote I/O blocks, and field junction boxes across the site. Plants in industries such as power generation, water and wastewater, metals, and general manufacturing use this module when they already have significant Genius infrastructure and need a reliable backbone to link distributed I/O and drives into a unified automation system.

In real-world projects, the GE IC687BEM731-AB is used to coordinate dozens of Genius nodes—valve islands, discrete and analog blocks, and specialty devices—over a single fieldbus that offers deterministic update behavior and mature diagnostic tools. Instead of running individual signal cables from every field device to the PLC, engineers segment the plant into Genius drops, each handled by a remote node, while this bus controller aggregates all that data into the CPU scan. This makes it applicable in control systems that prioritize robust, time-predictable communication with distributed equipment, including brownfield upgrades where existing Genius cabling and nodes must be preserved

Because of its dedicated handheld monitor port and built-in diagnostics, the GE IC687BEM731-AB also serves maintenance teams who need to troubleshoot network issues quickly without shutting down entire lines. In day-to-day operations, it becomes the communication hub that keeps central logic tightly synchronized with remote I/O, drives, and subsystems, which directly impacts production uptime, alarm integrity, and safety interlocks across the facility.

The GE IC687BEM731-AB is a Genius Bus Controller module designed for GE Fanuc PACSystems / RX7i-class racks, acting as the primary interface between the PLC backplane and the Genius fieldbus network. It is a communication module rather than standard I/O; its core purpose is to send and receive cyclic Genius data, handle global data and datagrams, and manage diagnostics for all nodes on the bus. In a typical system, the CPU executes the control program while the GE IC687BEM731-AB takes care of packaging I/O images, transmitting them over Genius, and presenting remote data back to the controller as if it were local I/O.

Within the control architecture, the GE IC687BEM731-AB sits in a rack slot on the main chassis and communicates with up to 32 Genius devices on the network, such as field I/O blocks, drives, and other intelligent nodes. It defines the Genius segment’s behavior—baud rate, addressing, and data formats—so that all attached devices remain synchronized with the PLC scan. For integrators, this module is what turns a conventional rack-based controller into a distributed control solution, extending I/O and control capability out into the plant via Genius nodes.

The GE IC687BEM731-AB is positioned as a high-performance, industrial-grade communication interface for legacy and mixed-generation systems that still rely on Genius as a proven fieldbus. Compared to generic gateways, it offers tight integration with the GE controller environment, including configuration through familiar tools and support for redundant applications in many architectures. This makes it particularly attractive in plants that want to keep Genius networks in service while upgrading CPUs or adding new remote I/O drops.

Functionally, the GE IC687BEM731-AB delivers robust performance as a bus controller, supporting data transfer rates up to 100 Mbps on suited implementations and coordinating deterministic data exchange with multiple Genius nodes. Its internal design supports built-in I/O device diagnostics, global data handling, and datagrams, so the controller can not only read and write I/O but also manage configuration and status functions over the same network. This capability improves response to faults and enables more sophisticated distributed control strategies, such as peer-to-peer coordination between nodes via global data.

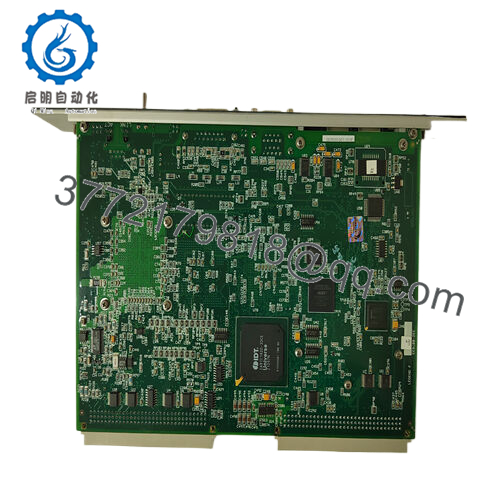

On the hardware side, the GE IC687BEM731-AB is built for rack mounting in a GE 90-70/RX7i-class chassis, drawing approximately 1.3 A from a 5 V backplane supply. Its industrial design includes isolation—typically rated around 1500 V RMS between logic and field circuits—to protect the controller from electrical disturbances on field wiring. Dimensions are compact enough to fit standard GE racks, often around 120 mm x 80 mm x 150 mm class, helping panel designers maintain consistent layouts even when adding communication capabilities.

A distinctive hardware feature of the GE IC687BEM731-AB is the dedicated Hand Held Monitor (HHM) port, which allows technicians to plug in a portable monitor for real-time diagnostics, configuration checks, and network troubleshooting without a laptop. This improves field service efficiency, especially in older installations where Genius is widespread and quick root-cause analysis is crucial to minimizing downtime.

Compatibility is one of the major strengths of the GE IC687BEM731-AB. It is designed to work seamlessly with GE Genius remote I/O blocks, drives, and other Genius-capable devices, making it straightforward to link legacy field hardware into newer PACSystems racks. The module supports up to 32 devices on a Genius segment, which may include combinations of discrete blocks, analog blocks, and specialty devices, all sharing the same deterministic bus. Configuration is handled with standard GE tools, leveraging established parameter sets for node addresses, baud rates, and global data structures.

From a long-term reliability standpoint, the GE IC687BEM731-AB is specified for industrial environments, with storage temperature ranges typically from about -40 °C to +85 °C and adherence to CE/UL/CSA safety certifications. Conservative design for thermal performance and isolation helps ensure stable operation over years of service, provided the module is installed in a well-ventilated, properly rated enclosure. For plants committed to maintaining Genius networks over the long term, this reliability is essential to avoiding unexpected communication failures and unplanned outages.

- IC687BEM731-AB

| Parameter | Value |

|---|---|

| Model | GE IC687BEM731-AB |

| Brand | GE Fanuc / PACSystems Genius family |

| Product Type | Genius Bus Controller communication module |

| System Platform | GE 90-70 / RX7i PACSystems rack |

| Bus Voltage (Backplane) | 5 V DC from rack backplane |

| Backplane Current Draw | Approximately 1.3 A at 5 V |

| Supported Field Devices | Up to 32 Genius nodes (I/O blocks, drives, etc.) |

| Data Transfer Rate | Up to 100 Mbps (application dependent) |

| Isolation Rating | Around 1500 V RMS between logic and field circuits |

| Hand Held Monitor Port | 1 dedicated HHM serial port for diagnostics |

| Mounting Method | Rack mount in GE chassis; DIN-compatible in some designs |

| Storage Temperature Range | -40 °C to +85 °C typical |

| Certifications | CE, UL, CSA industrial safety approvals |

IC687BEM731 – Base part number for the same Genius Bus Controller, functionally equivalent to GE IC687BEM731-AB in most control applications.

IC660BBD022N – Genius discrete I/O block that operates as a remote node controlled over the bus by GE IC687BEM731-AB.

IC670GB1002G – Genius field I/O module that can appear as another node on the same Genius network managed by this bus controller.

IC200GBI001-KL – VersaMax Genius Network Interface that allows newer VersaMax racks to coexist on a Genius segment under GE IC687BEM731-AB.

IC693CGB001 – Genius communication module for Series 90-30, used in systems where multiple Genius segments or controllers must coordinate.

IC687BEM733 – Related Genius bus or communication module variant used where alternative or expanded features are required (model family variant)

IC695CPU3xx / CPU31x – PACSystems CPUs commonly paired with GE IC687BEM731-AB in RX7i-class control systems.

Before installing the GE IC687BEM731-AB, engineers should confirm that the target rack has sufficient 5 V capacity to supply the 1.3 A draw, factoring in all other modules and future expansion. Rack location and cabinet design must support adequate airflow and temperature control, staying within environmental limits for both the controller and the bus module. On the fieldbus side, careful planning of Genius trunk length, drop cables, termination, and shielding is essential to maintain signal integrity and minimize reflections and noise.

Addressing and configuration are critical. Each Genius node must be assigned a unique address, and baud rate plus global data configuration should be documented and verified before commissioning. During startup, technicians should use the Hand Held Monitor port and controller diagnostics to confirm that the GE IC687BEM731-AB recognizes all expected nodes and that I/O data is updating consistently. Periodic maintenance should include inspection of backplane and bus connectors, verification of grounding and shielding continuity, and review of diagnostic logs for recurring communication or device errors.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626