Description

What This Product Solves

In industrial automation setups built around the GE Fanuc Series 90-30 PLC platform, integrating with DeviceNet networks often presents challenges when legacy or third-party devices need to exchange data reliably with the controller. Many engineers struggle with limited native support for DeviceNet in older PLC racks, leading to custom gateways, extra wiring complexity, inconsistent polling, or communication drops that compromise process control reliability and increase troubleshooting time.

GE IC693DNS201-BD directly tackles these issues by acting as a dedicated DeviceNet slave module, allowing the Series 90-30 PLC to function as a network server (slave) on a DeviceNet fieldbus. This becomes essential in environments where the PLC must respond to polled requests from a DeviceNet master—such as a scanner in a Rockwell system, an ABB controller, or other industrial devices—while providing real-time status, control data, or alarms. Typical situations include retrofitting existing 90-30 systems into larger, multi-vendor networks, or adding DeviceNet-compatible sensors, drives, valve actuators, or I/O blocks without replacing the core PLC.

GE IC693DNS201-BD ensures high reliability in I/O signal exchange over DeviceNet by handling up to 255 bytes of input and output data, supporting EDS file configuration for seamless integration, and delivering stable performance in noisy electrical environments common to factory floors. For engineers focused on maintaining system stability and avoiding costly downtime in process control applications, this module offers a straightforward way to bridge the gap between the Series 90-30 architecture and modern fieldbus requirements, reducing engineering overhead and preserving investments in proven hardware.

How the Product Works & Fits into a System

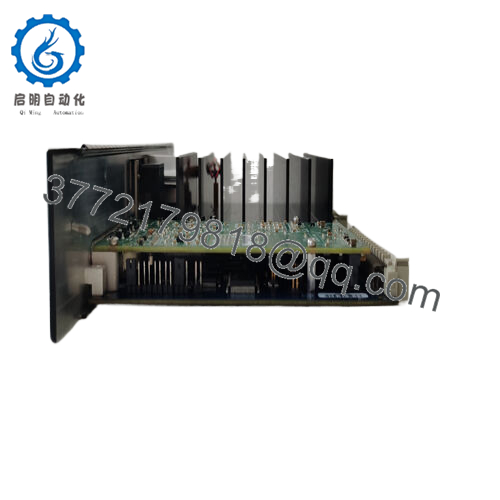

GE IC693DNS201-BD is a DeviceNet slave communications module that plugs into any available slot (except 0 and 1) in a Series 90-30 baseplate or expansion rack. It operates exclusively as a slave device on the DeviceNet network, meaning it responds to requests from a master device rather than initiating communication. The module connects via a standard 5-pin DeviceNet phoenix-style connector, supporting the CAN-based protocol at baud rates up to 500 kbps.

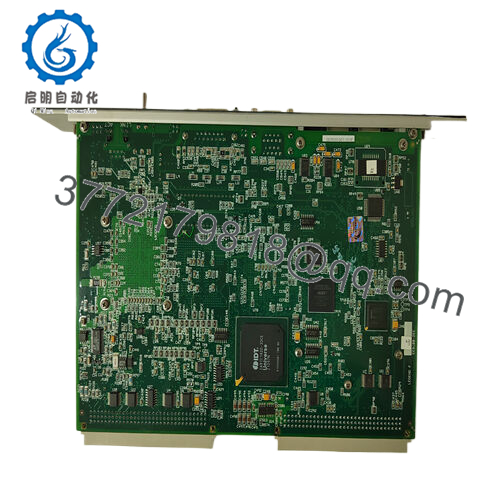

In the automation stack, GE IC693DNS201-BD sits in the I/O/communications layer, interfacing directly with the PLC CPU through the backplane. It maps up to 255 bytes of PLC %I (input) and %Q (output) memory to DeviceNet explicit and polled messaging, allowing the master to read discrete/analog status from the PLC and write commands or setpoints. Configuration occurs via an RS-232 serial port (9-pin D-sub) using GE’s configuration software or compatible tools that import the module’s EDS file, defining connection points, data sizes, and polling behavior.

The module includes three DeviceNet-compliant LEDs for network, module, and I/O status, plus built-in diagnostics visible in the PLC reference tables. While it does not support master functionality or redundancy on its own, it fits well in systems where the Series 90-30 acts as a subordinate controller or data concentrator. This positioning enables clean, deterministic data flow in distributed architectures, making GE IC693DNS201-BD a reliable link for integrating the 90-30 into broader DeviceNet ecosystems without disrupting existing ladder logic or requiring major rewiring.

Technical Highlights Summary

| Specification | Details |

|---|---|

| Model Number | IC693DNS201-BD |

| Brand | GE Fanuc (now Emerson) |

| Type | DeviceNet Slave Communications Module |

| Input Voltage | 5 V DC (from backplane) |

| Operating Temp Range | 0 to +60 °C |

| Mounting Style | Series 90-30 rack slot (not 0 or 1) |

| Dimensions | Standard Series 90-30 module size (approx. 145 x 93 x 135 mm) |

| Weight | Approx. 0.5 kg |

| Interface/Bus | DeviceNet (5-pin connector), RS-232 config port |

| Compliance | CE, UL, equivalent industrial standards |

| Supported Protocols | DeviceNet slave (polled, explicit messaging) |

| Typical Power Draw | 450 mA at 5 V DC |

- IC693DNS201-BD

Real-World Benefits

Selecting GE IC693DNS201-BD delivers dependable DeviceNet connectivity that keeps your Series 90-30 system responsive and integrated in multi-vendor environments. Engineered for consistent performance in industrial automation, it minimizes communication faults that could trigger false process interlocks or missed alarms, helping maintain stable operations even during network traffic spikes or minor wiring issues. The clear LED diagnostics and straightforward EDS-based setup reduce commissioning time and let maintenance teams quickly identify whether a problem lies in the network, cabling, or master device.

Over the long term, GE IC693DNS201-BD supports easier system expansions and migrations by preserving the value of installed 90-30 hardware while opening access to DeviceNet-capable field devices. This approach cuts engineering overhead associated with custom interfaces or protocol converters, lowers spare parts complexity, and ensures reliable data exchange that contributes to overall process uptime and efficiency in demanding control applications.

Typical Use Cases

GE IC693DNS201-BD is frequently deployed in manufacturing and process industries where the Series 90-30 PLC needs to integrate into a DeviceNet-dominant network for reliable slave-side operation. In automotive assembly lines, it enables the PLC to provide machine status, fault codes, or recipe data to a central DeviceNet scanner overseeing robots, conveyors, and weld controllers, ensuring synchronized operation in high-speed production.

Food and beverage facilities use GE IC693DNS201-BD for connecting to DeviceNet-enabled valve manifolds, level sensors, or motor starters in packaging and bottling lines, where continuous uptime and clean signal transmission are critical to avoid contamination risks or downtime. In material handling systems, such as warehouse automation or bulk processing plants, the module supports polled data exchange for proximity sensors and actuators under harsh conditions with electrical noise, vibration, and temperature variations typical of industrial environments. Across these applications, GE IC693DNS201-BD proves valuable for critical system uptime in process control environments requiring deterministic, multi-vendor fieldbus communication.

Compatible or Alternative Products

- IC693DNS201 – Base version without the -BD suffix, functionally equivalent in most applications

- IC693CMM311 – Communications coprocessor module for other protocols like Modbus or CCM

- IC693BEM331 – Genius Bus Controller for legacy Genius I/O networks as an alternative fieldbus

- IC693PBM200 – PROFIBUS Master module when switching to PROFIBUS instead of DeviceNet

- IC693PBM201 – PROFIBUS Slave module for slave-side integration on PROFIBUS DP

- IC693DSM302 – Motion control module if DeviceNet is used alongside servo drives

- IC693CPU374 – Higher-performance CPU with built-in Ethernet, for modernized 90-30 systems

- IC695PNS001 – RX3i PROFINET scanner as a migration path to newer Emerson PACSystems platforms

Setup Notes & Maintenance Insights

Before installing GE IC693DNS201-BD, confirm the Series 90-30 rack has an available slot (not power supply or CPU slot) and that backplane power is stable. Verify DeviceNet network baud rate and node address match the master’s configuration, using the RS-232 port and appropriate software to load the EDS file and map I/O data ranges. Ensure proper DeviceNet cabling with drop lines, terminators, and shielding grounded per ODVA guidelines to avoid signal integrity issues. Check for sufficient 5 V DC backplane capacity if the rack is heavily populated.

Ongoing maintenance involves periodic LED checks during operation: Network and Module LEDs should be steady green for healthy status, while I/O LED indicates data activity. Inspect the DeviceNet connector and cable for wear or loose connections annually, especially in vibrating or dusty areas. Use PLC diagnostics to monitor communication errors or timeouts in reference tables, and test polling response with the master device during scheduled shutdowns. Keeping configuration backups and firmware (if applicable) current helps prevent surprises during network changes or replacements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626