Description

In every Series 90-30 system, one component quietly determines whether the entire rack lives or dies the moment the panel door closes: the power supply. Too many projects treat it as an afterthought until the first hot summer day, a voltage sag, or a startup inrush causes the 5 V backplane rail to collapse and the CPU to fault. The result is either chronic nuisance trips or the expensive over-spec of a much larger supply “just to be safe.” The GE IC693PWR330 High-Capacity 120/240 VAC Power Supply was engineered specifically to end that uncertainty in demanding industrial automation environments.

Plants reach for the GE IC693PWR330 when standard 30 W supplies no longer cut it: large 10-slot racks fully loaded with analog cards, multiple communication modules, heavy output loading, or systems running in hot motor control centers with poor power quality. It becomes essential in water treatment plants, automotive assembly lines, food & beverage facilities, and any process control application where the PLC must ride through brownouts, start large numbers of output triacs simultaneously, and still deliver rock-solid 5 V, 24 V, and isolated 24 V rails under full load at 60 °C ambient. Delivering a true 30 watts continuous across all three outputs (with 50 W peak capability), the GE IC693PWR330 removes the guesswork and lets engineers load racks to the published limits without constant derating calculations.

The GE IC693PWR330 occupies the left-most slot of any Series 90-30 baseplate (5- or 10-slot, CPU or expansion/remote). It converts 85–264 VAC (or optionally 100–300 VDC) into three independently regulated outputs: 30 W total shared across +5 V (backplane logic), +24 VDC (relay/isolation power for output modules), and a separate +24 VDC isolated port for powering field devices or analog loops. Unlike lower-capacity supplies, the 24 V relay output is rated for the full 30 W when the 5 V rail is lightly loaded—perfect for racks with many IC693MDL940 or IC693MDL330 output modules.

Overvoltage, overcurrent, and overtemperature protection are built in, with a diagnostic contact that closes on any fault for remote alarming. A front-panel LED bar shows load percentage in 25 % increments, so operators can spot an overloaded rack long before it trips. The supply is fully compatible with redundancy cables (IC693CBL303/304) if you need true dual-supply failover in critical applications.

| Specification | Details |

|---|---|

| Model Number | IC693PWR330 |

| Brand | GE (now Emerson) |

| Type | High Capacity Power Supply Module |

| Input Voltage | 85–264 VAC or 100–300 VDC, 47–63 Hz |

| Operating Temp Range | 0 °C to 60 °C (full rating) |

| Mounting Style | Left-most slot in any Series 90-30 baseplate |

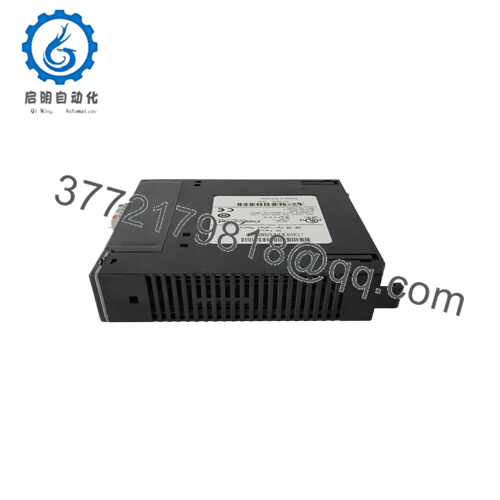

| Dimensions | 147 mm × 133 mm × 113 mm (deeper than standard I/O) |

| Weight | ≈ 900 g |

| Interface/Bus | Series 90-30 backplane + diagnostic contact |

| Compliance | CE, UL, CSA, ATEX Zone 2, RoHS |

| Supported Protocols | Native to all Series 90-30 CPUs and networks |

| Typical Power Draw | 125 VA max from AC line at full load |

- IC693PWR330

- IC693PWR330

Choosing the GE IC693PWR330 means you finally get to use the full published current ratings of every I/O card without derating spreadsheets. The triple-output design with generous 24 V headroom keeps output modules happy during simultaneous switching surges (think conveyor starts or valve banks opening), while the isolated 24 V port eliminates ground loops when powering transmitters in the same rack. The supply’s 50 W peak rating for one second handles the worst-case inrush of a fully loaded 10-slot rack without dropping a volt.

Maintenance teams love the load-monitoring LEDs and the fact that the diagnostic contact can be wired directly to a spare input for immediate HMI alarming. In practice, these supplies routinely run 15–20 years in 24/7 service with zero intervention beyond occasional terminal tightening. The GE IC693PWR330 turns a component that used to be a weak link into one you simply forget about.

You’ll find the GE IC693PWR330 powering critical Series 90-30 racks in municipal water filtration plants riding through frequent lightning-induced sags, on automotive paint lines with dozens of high-inrush solenoid valves, and in remote oil & gas skids where 60 °C ambients and questionable generator power are the norm. It is the default choice any time maximum I/O density, continuous uptime, and clean power are non-negotiable.

GE IC693PWR321 – Standard 30 W supply, 120/240 VAC only

GE IC693PWR322 – Standard 30 W with 24 VDC input option

GE IC693PWR328 – 48 VDC input version for telecom/battery plants

GE IC693PWR331 – 24 VDC input high-capacity supply

GE IC693PWR332 – 12 VDC input variant (rare)

GE IC694PWR330 – Direct RX3i equivalent with same ratings

GE IC693CBL303/304 – Redundancy cables for dual-supply setups

Before installing the GE IC693PWR330, confirm your incoming line voltage and that the rack’s left-most slot is empty (it will not fit elsewhere). Use at least 14 AWG for AC input and ground, and leave 50 mm clearance above and below for convection cooling—critical at full load in 60 °C environments. Torque AC terminals to 12 in-lb and verify the grounding stud is bonded to cabinet ground. If you’re using the diagnostic contact, wire it to a spare input or annunciator before powering up.

Ongoing care is minimal: check the load LEDs during routine walk-throughs and clean the front grille if the panel is in a dusty area. Retorque AC terminals every two years. The supply has no field-replaceable fuses—any fault trips the internal protection and requires replacement, but that event is exceptionally rare in properly designed systems.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626