Description

In modern industrial automation and process control systems, unexpected power interruptions pose a serious risk—not just to equipment, but to the integrity of active program data, retentive variables, and runtime states stored in volatile CPU memory. A sudden loss of power can corrupt user memory, force lengthy restarts with data reloads, or even trigger unsafe conditions in ongoing processes, leading to extended downtime and potential production losses. This issue is amplified in distributed setups where controllers manage critical loops, data logging, or coordinated motion across harsh environments with unstable utility feeds.

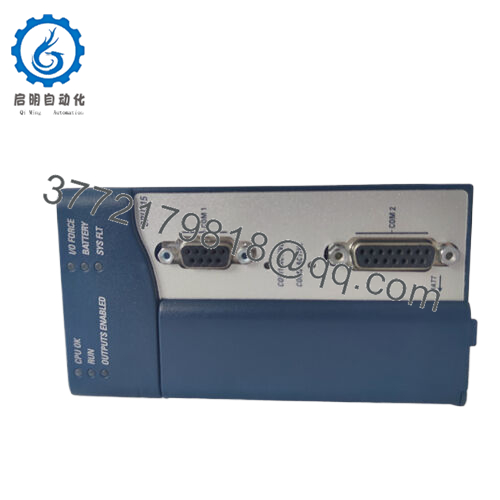

The GE IC695ACC400-AA tackles this directly as a capacitor-based Energy Pack for PACSystems RX3i controllers, eliminating the need for traditional battery maintenance while ensuring graceful shutdown behavior. Designed specifically for CPE302, CPE305, and CPE310 CPUs, the GE IC695ACC400-AA supplies hold-up power long enough for the processor to transfer all volatile contents to non-volatile flash storage. In high reliability applications—such as those requiring uninterrupted process control or compliance with strict availability standards—this module prevents data loss without the drawbacks of periodic battery replacements, chemical degradation, or disposal concerns.

Engineers often specify the GE IC695ACC400-AA in greenfield designs or upgrades where long-term maintenance reduction is a priority, particularly in remote or regulated facilities. Its robust construction supports operation in demanding conditions, making it indispensable for achieving critical system uptime in industrial automation platforms that cannot tolerate memory resets.

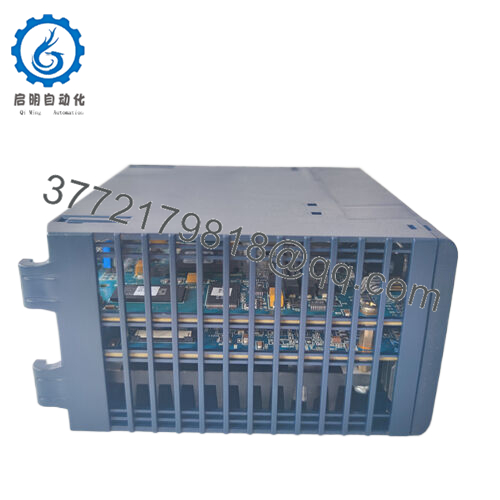

The GE IC695ACC400-AA attaches to the left side of a compatible RX3i CPU module and connects via a dedicated cable (typically IC695CBL001), integrating seamlessly into the controller’s power management architecture. While the main system power is present, it continuously charges from the 24V DC rail, reaching full capacity quickly and monitoring its own status.

Upon detection of primary power failure, the Energy Pack instantly bridges the gap, providing regulated output to sustain CPU operation for the time needed to complete an orderly write of application memory, registers, and diagnostic buffers to onboard flash. This positions it as a critical accessory in the control layer of the automation stack, complementing the CPU without occupying backplane slots or interfering with I/O expansion.

Status feedback flows back to the CPU for operator visibility, including charging state and readiness indicators that appear on the controller’s LEDs or via the programming software. The GE IC695ACC400-AA requires no additional protocols beyond the native RX3i framework, ensuring low-latency response and straightforward diagnostics in both standalone and redundant configurations.

| Specification | Details |

|---|---|

| Model Number | IC695ACC400-AA |

| Brand | GE (now Emerson) |

| Type | CPU Energy Pack (Capacitor-based) |

| Input Voltage | 24V DC (charged from system rail) |

| Operating Temp Range | 0°C to +60°C |

| Mounting Style | Side-mounted to compatible CPU |

| Dimensions | 140 mm x 124 mm x 25.4 mm |

| Weight | Approx. 0.4 kg |

| Interface/Bus | Dedicated cable to RX3i CPU |

| Compliance | CE, RoHS, UL |

| Supported Protocols | Native RX3i power management |

| Typical Power Draw | Minimal (charging <5W) |

- IC695ACC400-AA

- IC695ACC400-AA

Opting for the GE IC695ACC400-AA brings immediate gains in system resilience by safeguarding against volatile memory loss during outages, which directly translates to preserved process states and faster recovery times. Unlike battery solutions, its capacitor technology offers a typical lifespan exceeding 10 years under normal temperatures, ensuring long-term performance with virtually no degradation concerns.

This design reduces engineering overhead associated with battery monitoring, scheduled replacements, or environmental compliance tracking. In deployed systems, the GE IC695ACC400-AA contributes to consistent uptime metrics, as the CPU can resume exactly where it left off post-power restoration.

Overall, the module enhances maintenance efficiency by shifting focus from reactive component swaps to proactive system health checks, allowing teams to allocate resources toward optimization rather than upkeep. Plants incorporating the GE IC695ACC400-AA frequently achieve lower total cost of ownership through minimized interruptions and extended intervals between interventions.

The GE IC695ACC400-AA sees regular use in water and wastewater treatment facilities, where controllers oversee pumping sequences and chemical dosing under variable power conditions, delivering critical system uptime even during grid fluctuations or generator transfers.

In food and beverage processing lines, it protects recipe parameters and batch records in RX3i-based controls, supporting continuous operation in refrigerated or washdown environments prone to electrical disturbances.

Pharmaceutical manufacturing also relies on it for validated processes requiring data integrity, ensuring retentive memory preservation in cleanroom setups with redundant power feeds but occasional switchover delays.

These process control environments benefit from the module’s ability to maintain state during brief outages, upholding compliance and productivity.

IC695CPE305 – Embedded Ethernet CPU commonly paired with this Energy Pack

IC695CPE310 – Higher-performance CPU variant requiring the same hold-up capability

IC695CPE302 – Entry-level compatible controller for cost-sensitive applications

IC695CBL001 – Required connection cable for Energy Pack installation

IC695ACC402 – Updated Energy Pack revision for newer CPE models

IC695CHS012 – Universal backplane supporting CPU and accessory mounting

IC695PSA040 – Multipurpose power supply feeding the 24V rail for charging

Before deploying the GE IC695ACC400-AA, confirm CPU compatibility (CPE302/305/310 only) and ensure the connecting cable is the correct length without excessive bends that could stress connectors. Verify sufficient clearance on the left side of the CPU for mounting and airflow, as restricted space can elevate internal temperatures.

Check initial charge status upon first power-up—full capacity may take several minutes, during which the CPU will indicate “charging” via diagnostics. For systems stored long-term, allow extra time for capacitor reformation.

Ongoing maintenance is minimal: periodically inspect the status via the controller’s software or LEDs for any fault indications, and visually check cable security during routine panel inspections. No battery tests or replacements are needed, but a functional verification during annual shutdowns—simulating power loss—confirms hold-up performance. These steps keep the GE IC695ACC400-AA ready for real-world events over its extended service life.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626