Description

The GE IC695CRU320-CA-EL (often referenced as IC695CRU320 with -CA-EL revision suffix) provides a purpose-built redundancy solution for engineers designing high-availability control systems in the PACSystems RX3i platform. In industrial automation and process control, unplanned downtime in critical applications—whether from CPU faults, power glitches, or field disruptions—can lead to significant production losses, safety risks, or regulatory violations. Standard single-CPU setups lack automatic failover, forcing manual intervention or system restarts that interrupt continuous processes. For applications demanding near-zero interruption, such as turbine controls, chemical reactors, or high-speed packaging lines, relying on basic controllers means accepting vulnerability or adding complex external redundancy schemes that increase cost and engineering effort.

GE IC695CRU320-CA-EL addresses this by enabling true Hot Standby redundancy with sub-second switchover, ensuring seamless transfer of control without logic disruption or I/O glitches. It becomes essential in setups where uptime is non-negotiable and scan times must remain deterministic even during failover. Without native redundancy like this, teams often oversize hardware, duplicate entire racks, or tolerate periodic stops for maintenance—adding unnecessary expense and complexity. GE IC695CRU320-CA-EL integrates directly into the RX3i architecture, pairing two CPUs with a dedicated redundancy link to deliver synchronized operation, automatic role switching (primary/secondary), and synchronized I/O updates. This approach maintains high reliability, supports online maintenance, and lets the system focus on stable execution rather than recovery from failures.

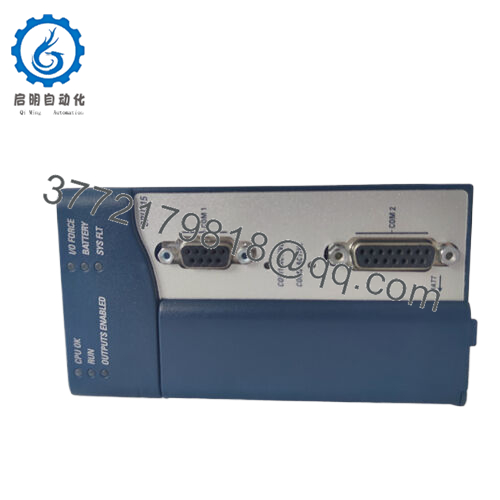

The GE IC695CRU320-CA-EL serves as the redundant CPU in the RX3i PACSystems, occupying two slots on the universal backplane and coordinating with a partner CPU via one or two IC695RMX128/228 Redundancy Memory Xchange modules for high-speed synchronization of logic state, data, and I/O. It features a 1 GHz Celeron-M processor executing ladder, structured text, function block, and C logic, with 64 MB battery-backed RAM and 64 MB non-volatile flash for substantial program size and data handling. Two independent serial ports (RS-232/RS-485) support Modbus RTU, SNPX, or programming, while an embedded Ethernet port enables SRTP, Modbus TCP, and Ethernet Global Data for HMI/SCADA connectivity.

In a redundant pair, the GE IC695CRU320-CA-EL maintains identical logic execution on both units, with the primary driving outputs and the secondary shadowing in hot standby. Switchover occurs in as little as one logic scan (minimum ~3 ms), triggered by faults, manual command, or link failure, with bumpless transfer to I/O and no process upset. It supports up to eight local racks and remote I/O via compatible interfaces, plus HART pass-through through suitable modules. Diagnostics include detailed fault LEDs, system logs, and status monitoring via Proficy Machine Edition. The -CA-EL revision incorporates firmware enhancements for improved interface monitoring with RMX/CMX modules and overall stability in redundant setups. Positioned as the core of high-availability architectures, GE IC695CRU320-CA-EL enables online upgrades, repairs, and expansions without halting production.

- IC695CRU320-CA-EL

| Specification | Details |

|---|---|

| Model Number | IC695CRU320-CA-EL |

| Brand | GE / Emerson (PACSystems RX3i) |

| Type | Redundancy CPU Module (Hot Standby) |

| Input Voltage | 5 VDC / 3.3 VDC backplane (from power supply) |

| Operating Temp Range | 0 to +60 °C |

| Mounting Style | RX3i universal backplane (2 slots) |

| Dimensions | Standard RX3i dual-slot (approx. 145 x 112 x 135 mm effective) |

| Weight | Approx. 1.0 kg |

| Interface/Bus | PCI/Serial dual backplane; Embedded Ethernet; Redundancy link via RMX |

| Compliance | CE, RoHS, UL Class I Div 2 |

| Supported Protocols | SRTP, Modbus TCP/RTU, EGD, HART Pass Through; Redundancy sync via RMX |

| Typical Power Draw | ~7-8 W (base, per CPU) |

Choosing GE IC695CRU320-CA-EL delivers true high-availability control with automatic failover that keeps processes running through CPU or link issues, minimizing production halts and protecting against single-point failures. Engineered for mission-critical industrial automation, its synchronized execution and fast switchover ensure bumpless transfer, maintaining tight loop control and consistent output states even during transitions.

The redundancy setup reduces maintenance downtime—swap or upgrade one CPU while the partner holds control, then resync without shutdown. This approach lowers risk in safety-rated or high-value operations and simplifies compliance with uptime-focused standards. Paired with Proficy tools, GE IC695CRU320-CA-EL supports efficient diagnostics and configuration, cutting troubleshooting time and engineering overhead while providing confidence in long-term, uninterrupted performance.

GE IC695CRU320-CA-EL is frequently deployed in power generation for turbine governor, exciter, or boiler controls where continuous operation prevents costly trips or restarts. In oil & gas refining or petrochemical plants, it manages critical sequences like compressor trains or reactor loops requiring zero process interruption. Discrete manufacturing applications—such as automotive assembly or high-volume bottling—use it for synchronized multi-line coordination under demanding uptime targets.

These scenarios emphasize harsh conditions, fast deterministic scans, and critical system uptime—areas where GE IC695CRU320-CA-EL provides reliable redundancy without the complexity of custom failover logic or external controllers.

Here are some related or alternative products within the RX3i family and beyond:

- IC695CRU320 (standard or other revisions like -EL) – Core redundancy CPU; -CA-EL includes specific firmware/interface improvements.

- IC695CPE330 – High-performance non-redundant CPU with dual Gigabit Ethernet and embedded PROFINET for demanding single-CPU setups.

- IC695CPE400 – Standalone advanced CPU with quad-core processing, PACEdge, and enhanced security for edge-enabled applications.

- IC695RMX128 – Redundancy Memory Xchange module (copper fiber) required for synchronization link in Hot Standby pairs.

- IC695RMX228 – Fiber-optic version of RMX for longer-distance redundancy links.

- IC695CPE310 – Mid-range single-slot CPU with less memory, suitable for non-redundant mid-size applications.

- IC695CRU320 variants (e.g., -EH, -EM) – Earlier/later firmware revisions with incremental enhancements.

- IC695ACC402 – Energy Pack for non-volatile data retention during power loss (recommended for both CPUs in pair).

Before installing GE IC695CRU320-CA-EL, confirm dual-CPU rack compatibility and that power supplies provide balanced current for both units plus RMX modules. Install the required IC695RMX128/228 (one or two for added link reliability) and verify fiber/copper cabling meets length and bend specs. Attach Energy Packs if battery-less retention is desired—connect cables securely and remove RTC battery tabs. Use Proficy Machine Edition to check/set firmware versions for redundancy features and perform initial sync tests in a bench setup before live deployment. Ensure adequate ventilation, as redundant pairs generate slightly more heat.

Ongoing maintenance includes monitoring primary/secondary status LEDs and redundancy link health during routine inspections—look for steady OK and active sync indications. Review fault logs and event queues in PME periodically, and test failover manually during planned outages to validate switchover timing and bumpless behavior. Inspect RMX connections and cables annually for wear or contamination, especially in dusty/vibrating environments. Firmware updates should align both CPUs; back up applications regularly via RDSD or CFast. Diagnostics feed into HMIs for proactive remote monitoring.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626