Description

In distributed industrial automation systems, engineers frequently encounter the limitations of centralized I/O architectures—long cable runs introduce noise, increase installation costs, complicate troubleshooting in expansive or hazardous areas, and hinder scalability as production demands grow. Adding remote points often requires custom gateways or protocol converters, risking data latency and reducing overall system flexibility.

The GE IC695NIU001-CK tackles this head-on by enabling a complete RX3i universal backplane to function as a high-performance remote I/O drop over standard Ethernet infrastructure. This Ethernet Network Interface Unit scans local RX3i and legacy Series 90-30 modules independently, then exchanges data seamlessly with master controllers via Ethernet Global Data (EGD), delivering deterministic updates without polling overhead or complex mapping.

The GE IC695NIU001-CK proves indispensable when modernizing existing RX3i installations for distributed control, incorporating remote monitoring in large facilities, or achieving modular integration in evolving process control setups. As a current-production revision, it incorporates the latest manufacturability enhancements and certifications, ensuring high reliability for I/O signals in continuous-operation industrial automation environments where wiring reduction and signal integrity directly impact uptime and maintenance costs.

The GE IC695NIU001-CK installs in the CPU slot of an RX3i universal backplane, managing full I/O scanning across the main rack and compatible Series 90-30 expansion racks. Ethernet connectivity demands at least one IC695ETM001 module in the backplane—the NIU leverages these 10/100 Mbps interfaces for all network traffic.

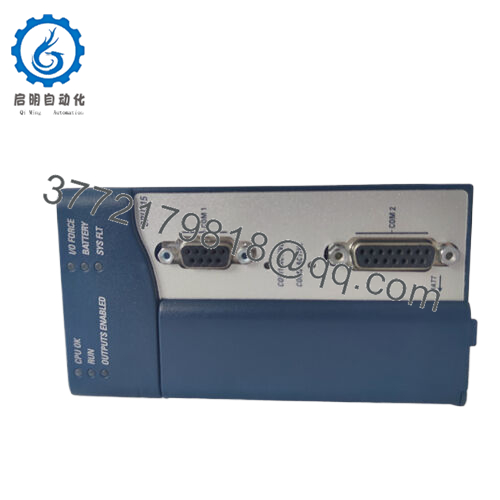

Configuration in Proficy Machine Edition defines EGD producer/consumer exchanges, mapping discrete, analog, and status references directly. Data flows bidirectionally and automatically once set, supporting update rates aligned with typical real-time process control requirements. Dual serial ports (RS-232 and RS-485) enable local Station Manager access, diagnostics, or Modbus RTU integration.

Front-panel LEDs provide clear visibility into module health, I/O activity, faults, and port status, while embedded diagnostics report detailed station information to the master. Within the automation stack, the GE IC695NIU001-CK serves as a robust remote I/O adapter, facilitating scalable architectures where central controllers focus on logic and visualization.

- IC695NIU001-CK

| Specification | Details |

|---|---|

| Model Number | IC695NIU001-CK |

| Brand | GE (Emerson) |

| Type | Ethernet Network Interface Unit (NIU) |

| Input Voltage | Backplane: 3.3 VDC (1.25 A nom.), 5 VDC (1.0 A nom.) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | RX3i universal backplane (CPU slot) |

| Dimensions | Approx. 145 mm x 140 mm x 40 mm (H x D x W) |

| Weight | Approx. 0.45 kg |

| Interface/Bus | RX3i PCI/serial backplane; Requires IC695ETM001 for Ethernet; RS-232/RS-485 serial |

| Compliance | UL, cUL, CE, RoHS, updated certifications |

| Supported Protocols | Ethernet Global Data (EGD); SRTP; Modbus RTU (serial) |

| Typical Power Draw | 6.25 W (combined 3.3V and 5V backplane) |

The GE IC695NIU001-CK offers proven signal reliability via mature EGD technology, maintaining low-latency transfers even in moderately loaded networks—critical for applications where intermittent updates could affect control quality. Engineered with the latest production refinements, it delivers long-term performance in challenging electrical environments, resisting issues common to parallel wiring like ground shifts or EMI degradation.

Maintenance becomes more efficient thanks to comprehensive LED feedback and automatic status reporting, enabling rapid fault localization without specialized tools. Integration within the RX3i platform stays intuitive, relying on established Proficy workflows and eliminating the need for proprietary adapters.

Ultimately, the value lies in substantial cost savings—reduced cabling lowers both initial deployment and future modifications—while the current revision ensures ongoing availability and compliance. The GE IC695NIU001-CK provides a dependable foundation for distributed systems that evolve over decades.

The GE IC695NIU001-CK commonly appears in pharmaceutical and food & beverage plants for remote batching stations and packaging lines, where distributed I/O supports precise data cycles amid strict hygiene and vibration challenges.

Oil & gas installations deploy it for pipeline monitoring or tank farm controls, ensuring high reliability across vast sites with potential EMI from motors and switches.

Manufacturing facilities, including metals processing and assembly, use it to extend I/O drops to robotic cells or conveyors, maintaining critical system uptime in process control environments demanding fast, noise-immune updates and easy modular additions.

IC695NIU001-BE – Earlier revision supporting up to eight ETM modules

IC695NIU001-CJ – Previous production revision with established field history

IC695NIU001-CL – Subsequent minor update variant

IC695NIU001-AA – Initial release for baseline compatibility

IC695ETM001 – Essential 10/100 Ethernet Transmitter Module (multiple supported)

IC695NKT001 – Kit with one NIU and one ETM for basic remote drops

IC695NKT002 – Kit with one NIU and two ETMs for redundant Ethernet

IC695PNC001 – PROFINET controller for migration to modern networks

Before installing the GE IC695NIU001-CK, validate backplane power supply capacity for the NIU plus all I/O and at least one IC695ETM001—high-capacity units suit dense configurations. Assign unique IPs to each ETM and confirm subnet match with the master controller.

Ensure adequate panel clearance for convection cooling and route Ethernet cables away from power lines to preserve signal quality. Test exchange definitions offline in Proficy Machine Edition to verify mapping and timeout settings early.

Routine maintenance involves periodic LED checks during plant walks for early detection of link or fault conditions, plus reviewing master-side status data for anomalies. Inspect serial and Ethernet connectors in corrosive or dusty settings, and conduct annual functional tests by simulating outputs. A pre-configured spare assembly (NIU + ETM) with your site-specific settings allows near-instant recovery.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626