Description

In expansive industrial automation and process control systems, achieving high reliability in CPU performance while handling larger program memory, faster execution, and expanded I/O capacity often strains standard processors, leading to bottlenecks in scan times, limited logic complexity, or challenges in supporting advanced option modules. This is especially pronounced in legacy upgrades or demanding applications where the system must manage thousands of I/O points, floating-point operations, and communication tasks without compromising deterministic control.

The GE IC697CPU781-JE addresses these demands as an expanded-memory Central Processing Unit in the GE Series 90-70 PLC family, delivering a 16 MHz 80386DX processor with enhanced capabilities over base models. It becomes critical in situations requiring robust program storage for complex ladder logic, structured text, or C blocks, such as coordinating multiple bus controllers or integrating specialty modules in industrial automation. Engineers commonly select the GE IC697CPU781-JE for scaling existing 90-70 installations, supporting hot-standby redundancy, or building systems that demand critical system uptime and precise timing in process control environments. Its architecture ensures consistent boolean execution rates and ample memory headroom, mitigating risks of overflow or slowdowns that affect less capable CPUs.

By providing scalable processing power and broad module compatibility, this CPU facilitates goals like improved response times, modular expansion, and long-term system stability in high-density I/O signal applications.

The GE IC697CPU781-JE resides in the primary VME rack of the Series 90-70 platform, executing user logic while interfacing with local and remote I/O via backplane and bus controllers. It scans programs cyclically, supporting ladder diagram, instruction list, and optional C programming, with built-in floating-point math for advanced calculations.

Integration into the automation stack is seamless: it communicates directly with discrete/analog modules in the rack, Genius or parallel bus expansions, and communication modules like Ethernet or LAN interfaces. Configuration and programming occur through GE tools such as Logicmaster 90-70 or CIMPLICITY Machine Edition, connected serially, parallel, or over Ethernet. The CPU manages interrupt-driven events, timed interrupts, and PID loops natively, while supporting redundancy through synchronized links for bumpless failover.

Diagnostics include comprehensive fault tables, battery-backed RAM retention, and status LEDs for run/stop, memory protect, and system health. In redundant setups, it coordinates with a backup unit via dedicated links. Overall, the GE IC697CPU781-JE anchors the control hierarchy, ensuring efficient data handling across the I/O architecture without overburdening the processor.

- IC697CPU781-JE

| Specification | Details |

|---|---|

| Model Number | IC697CPU781-JE |

| Brand | GE (Fanuc/Emerson) |

| Type | Expanded Memory Central Processing Unit (CPU) |

| Input Voltage | 5 V DC (from backplane) |

| Operating Temp Range | 0°C to 60°C |

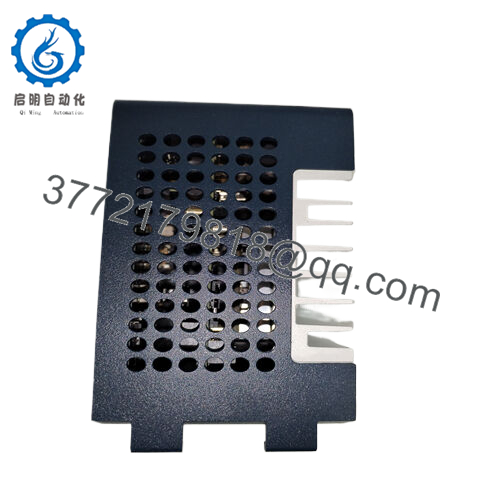

| Mounting Style | VME rack (single slot) |

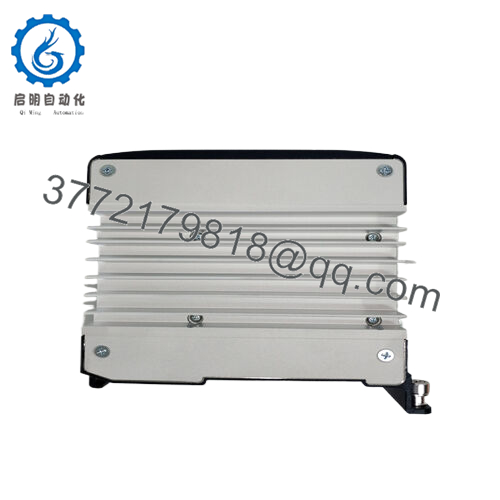

| Dimensions | Standard IC697 module (approx. 11.2 x 1.3 x 10 inches) |

| Weight | Approx. 1.8 kg (4 lbs) |

| Interface/Bus | VME backplane with parallel I/O bus support |

| Compliance | CE, UL, CSA (typical for series) |

| Supported Protocols | Proprietary GE with option module extensions |

| Typical Power Draw | Approx. 20 W |

Deploying the GE IC697CPU781-JE equips systems with a processor engineered for sustained high-performance operation in Series 90-70 environments, where rapid boolean execution and ample memory directly enhance control precision and scalability.

Its robust design ensures long-term performance by handling intensive logic without thermal or timing issues, reducing risks of faults that propagate through the process. This contributes to maintenance efficiency, as detailed fault diagnostics and non-volatile storage minimize debugging time and data loss during power cycles.

Integration advantages are clear—the GE IC697CPU781-JE reduces engineering overhead through broad compatibility with existing modules and straightforward redundancy setup, preserving investments while enabling growth. The fast scan rates support responsive loops, ideal for coordinated motion or batch sequencing.

In real terms, the value emerges in operational confidence: expanded capacity that supports evolving demands, fostering reliability and allowing teams to prioritize application enhancements over hardware limitations.

The GE IC697CPU781-JE is frequently used in manufacturing sectors like automotive or pharmaceuticals, where it manages extensive discrete I/O for assembly lines under continuous operation, tolerating vibration and electrical interference.

In utilities or chemical processing, it excels in process control environments requiring precise analog handling and uninterrupted uptime, coordinating remote drops across large facilities. Power generation applications leverage it for critical system uptime in turbine or boiler control, supporting fast interrupt processing amid harsh ambient conditions.

These scenarios emphasize needs for memory-intensive programs and fault-tolerant execution in distributed setups.

GE IC697CPU782 – Higher-performance successor with additional features for demanding tasks

GE IC697CPU780 – Base model for smaller applications or cost-sensitive upgrades

GE IC697CPU771 – Lower-tier CPU for basic control needs

GE IC697CPX935 – Single-slot high-end CPU alternative for modern expansions

GE IC697CPX782 – Complementary redundant-capable processor

GE IC697CGR935 – Redundancy link module for hot-standby configurations

GE IC697PWR711 – Compatible power supply for rack operation

Before powering up the GE IC697CPU781-JE, verify battery condition and installation for RAM retention, along with firmware compatibility via your programming software version. Confirm rack power supply rating supports the CPU’s draw plus other modules, and ensure keyswitch position aligns with intended mode—typically “Run with Outputs Enabled” for production.

Slot it in the designated CPU position (usually slot 1) with secure backplane connection.

Maintenance focuses on periodic battery replacement (every 2-5 years depending on temperature), LED status checks for faults or overrides, and regular fault table clearance/review in software. Dust inspection in the rack and fan filter cleaning (if equipped) prevent overheating; consider a yearly program backup and validation scan.

These measures promote reliable, extended service life consistent with the platform’s reputation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626