Description

In industrial automation and process control environments, expanding programmable logic controller (PLC) memory capacity is often critical when complex logic programs, large data tables, or extensive register storage push against built-in limits, leading to constraints on application size, reduced scan times, or the inability to add new features without major hardware overhauls. Legacy systems like GE’s Series 90-70 PLCs frequently encounter these issues during upgrades or expansions in long-running facilities, where adding more I/O points or advanced control algorithms demands additional reliable memory without sacrificing rack space or system integrity.

The GE IC697MEM735 addresses this need by providing a high-capacity CMOS expansion memory solution specifically engineered for high reliability in demanding industrial automation setups. As a 512 KB 32-bit expansion module, the GE IC697MEM735 enables engineers to scale logic and data memory for CPUs such as the IC697CPU780, 781, 782, 788, and 789, supporting larger programs that include intricate sequencing, data logging, or communication handling. This becomes essential in situations where process control requires handling thousands of registers or complex ladder logic without compromising performance—common in batch processing, machine control, or distributed systems. With battery-backed retention and built-in parity checking, it ensures program integrity during power cycles, minimizing risks of corruption that could halt production in critical operations.

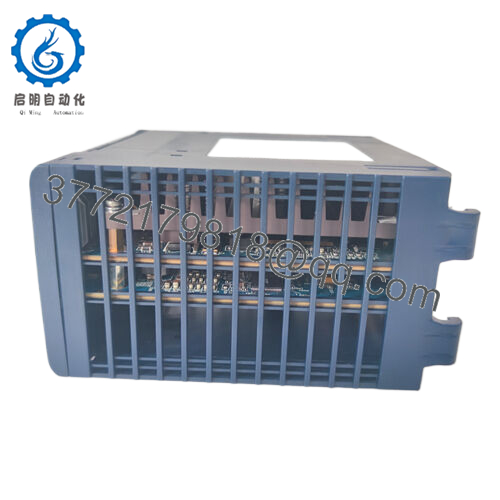

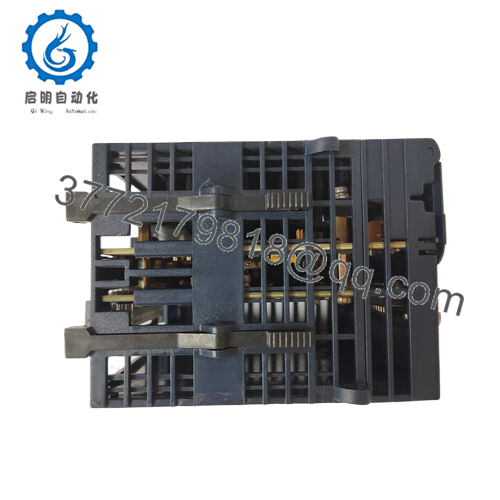

The GE IC697MEM735 operates as a daughterboard-style CMOS expansion memory module within the GE Series 90-70 PLC architecture, mounting directly onto compatible CPU boards without occupying an additional VME rack slot. It integrates seamlessly into the CPU’s memory space, providing 512 KB of volatile RAM for user program logic, data tables, and registers, while leveraging the host CPU’s lithium battery for retention during power loss.

Positioned in the control layer of the automation stack, the GE IC697MEM735 works in tandem with the CPU over the VME backplane, allowing direct access for fast execution cycles. The module supports parity error detection on every byte, with the CPU performing continuous checksum validation in the background to flag issues promptly via fault tables. Non-volatile flash options in related variants preserve certain data independently, but the primary SRAM in this configuration relies on battery backup for up to six months nominal without power. It fits into both standalone and redundant Series 90-70 configurations, interacting with I/O modules, communication processors, and programming software like Logicmaster or CIMPLICITY Machine Edition without requiring special protocols—just standard VME bus communication for deterministic performance in process control environments.

| Specification | Details |

|---|---|

| Model Number | IC697MEM735 |

| Brand | GE (Emerson) |

| Type | CMOS Expansion Memory Module |

| Input Voltage | 5V DC (via VME backplane) |

| Operating Temp Range | 0°C to 60°C |

| Mounting Style | Daughterboard on CPU module |

| Dimensions | Compact board (fits within CPU slot) |

| Weight | Approx. 0.2 kg |

| Interface/Bus | VME backplane |

| Compliance | CE, UL, CSA (typical for series) |

| Supported Protocols | N/A (memory expansion only) |

| Typical Power Draw | 2.25A at 5V DC (combined with CPU) |

Opting for the GE IC697MEM735 delivers a module engineered for sustained reliability in legacy PLC deployments, where its parity checking and error reporting help maintain program accuracy over years of operation, reducing the likelihood of undetected faults that could lead to process deviations. The battery-backed design ensures long-term performance by preserving critical logic and data through outages, supporting uninterrupted restarts and minimizing recovery time in high-uptime applications.

- IC697MEM735

- IC697MEM735

Integration efficiency is a key advantage; as a slot-saving daughterboard, it reduces engineering overhead during system expansions—no need to reconfigure rack layouts or add power supplies. This approach preserves valuable space in crowded panels while enabling straightforward scaling of memory-intensive features like expanded alarm handling or recipe storage. Overall, the GE IC697MEM735 contributes to lower maintenance demands through its robust error detection, allowing teams to focus on optimization rather than constant troubleshooting, and it extends the viable life of Series 90-70 investments without forcing premature migrations.

The GE IC697MEM735 is commonly deployed in industries requiring robust, large-scale PLC control under continuous operation, such as power generation facilities where it supports extensive logic for turbine sequencing or substation monitoring, ensuring critical system uptime amid variable loads. In water treatment and wastewater plants, the module accommodates complex data tables for multi-stage processes, handling harsh environmental conditions with reliable memory retention.

Manufacturing sectors, particularly automotive or metals processing, benefit from its capacity for fast cycle times in coordinated motion control or assembly lines, where large programs manage hundreds of I/O points in process control environments demanding high reliability. Across these applications—often involving distributed racks or remote stations—the GE IC697MEM735 provides the necessary expansion for evolving requirements without compromising performance in industrial automation setups focused on long-term stability.

IC697MEM731 – 128 KB version for smaller program expansions

IC697MEM732 – 256 KB with additional non-volatile flash for persistent storage needs

IC697MEM733 – Standard 256 KB alternative for moderate capacity requirements

IC697MEM719 – Lower-capacity option suited to earlier CPU models like 771/772

IC697MEM717 – Entry-level expansion for coprocessor or basic CPU enhancements

IC697MEM715 – Legacy smaller memory board for minimal upgrades

IC697CPU782 – Compatible high-performance CPU often paired with this module

Prior to installing the GE IC697MEM735, confirm compatibility with your specific CPU revision (typically 780-series) and ensure the rack power is off to avoid damage during daughterboard attachment—align connectors carefully and secure standoffs/screws for solid contact. Check the host CPU’s lithium battery condition, as it directly supports memory retention; a fresh IC697ACC701 battery is recommended if nearing end-of-life.

In operation, maintenance is straightforward: monitor PLC fault tables for any parity errors during routine checks, and inspect the board for dust or loose connections in harsh environments. Battery replacement should occur annually or based on diagnostics—always insert the new battery before removing the old to prevent data loss. Periodic program backups via programming software provide an extra safeguard. These steps help sustain reliable performance across extended service life in industrial settings.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626