Description

In the high-stakes world of industrial automation, where process control demands unwavering precision and I/O signal integrity can make or break operational continuity, engineers often grapple with the vulnerabilities of distributed control systems. Sudden spikes in electrical noise, inconsistent field device communications, or integration hiccups in modular architectures can cascade into production halts, safety risks, or costly compliance failures. This is especially true in environments like chemical plants or utilities, where legacy DCS setups need to evolve without full overhauls. Enter the GE IC752DPA062, a robust digital output module designed to fortify signal reliability and system stability. It tackles these challenges by providing isolated, high-density outputs that shield against electromagnetic interference, ensuring clean command signals reach actuators, valves, or relays even amid harsh electrical environments. In process control setups, where high reliability is paramount for maintaining uptime in continuous operations, GE IC752DPA062 shines as an essential upgrade for expanding I/O capacity without compromising on fault tolerance. Teams deploying it in retrofit projects or new builds appreciate how it streamlines industrial automation workflows, reducing the engineering time spent on noise mitigation or redundant wiring. By focusing on seamless I/O signal handling, this module empowers control rooms to respond faster to process variables, minimizing downtime from false trips or delayed responses. Whether you’re scaling a SCADA-integrated system or hardening against grid fluctuations, GE IC752DPA062 delivers the dependable backbone needed to keep complex automation loops running smoothly, turning potential vulnerabilities into strengths for long-term operational resilience.

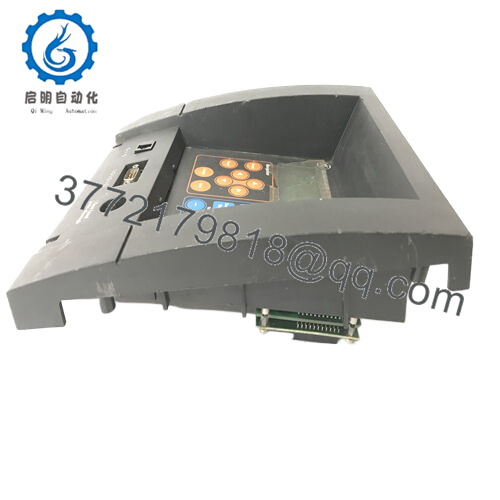

The GE IC752DPA062 operates as a versatile digital output powerhouse within GE’s Series 7500 I/O architecture, slotting neatly into backplane systems to extend the reach of your central controller. Imagine it as the reliable intermediary that translates high-level commands from a PLC or DCS—say, from GE’s RXi or PAC8000 platforms—into precise, low-level signals for field devices. It drives up to 16 discrete outputs with opto-isolation to prevent ground loops or surges from propagating back to sensitive logic, all while supporting hot-swappable insertion for minimal disruption during expansions. Positioned at the edge of the automation stack, it interfaces via the high-speed Carrier Bus with adjacent analog or communication modules, forming a cohesive I/O subsystem that feeds real-time status data upward to supervisory layers. Built-in diagnostics, including per-channel fault detection and heartbeat monitoring, allow it to flag issues like overcurrent or open circuits early, integrating effortlessly with protocols such as Modbus RTU or Ethernet/IP for remote polling. In redundancy setups, pair it with a duplexed counterpart to enable bumpless failover, ensuring process control continuity even if one module encounters a transient fault. This modular fit reduces cabling complexity in cabinet designs, letting you concentrate I/O density without sprawling layouts, and its compatibility with GE’s Proficy software suite simplifies configuration—think drag-and-drop mapping of outputs to control tags. Overall, GE IC752DPA062 enhances system responsiveness by delivering consistent signal conditioning, making it a go-to for environments where every millisecond of latency or signal drop counts toward overall efficiency.

| Specification | Details |

|---|---|

| Model Number | IC752DPA062 |

| Brand | GE (now Emerson) |

| Type | Digital Output Module |

| Input Voltage | 24 V DC (backplane powered) |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN rail / backplane snap-in |

| Dimensions | 150 x 75 x 50 mm (approx.) |

| Weight | 0.45 kg |

| Interface/Bus | Series 7500 Carrier Bus |

| Compliance | CE, UL, RoHS, ATEX (zone 2 optional) |

| Supported Protocols | Modbus RTU, Ethernet/IP |

| Typical Power Draw | 5 W |

- IC752DPA062

Opting for the GE IC752DPA062 means investing in a level of reliability that directly bolsters your automation ecosystem’s endurance. Engineered for the rigors of continuous industrial automation, it ensures long-term performance by isolating outputs against common culprits like inductive kickback from solenoids, which in turn safeguards upstream controllers from erratic behavior and extends their lifespan. This isn’t just about avoiding failures—it’s about the peace of mind that comes from predictable operation, where diagnostics preemptively surface anomalies via integrated LEDs or network alerts, slashing mean time to repair by enabling targeted interventions rather than full-system scans. Maintenance crews find their routines streamlined, as the module’s field-replaceable design and self-testing capabilities cut down on ladder climbing or panel disassembly during routine checks.

Beyond durability, GE IC752DPA062 eases integration burdens, reducing engineering overhead in multi-vendor environments. Its plug-and-play alignment with GE’s I/O carriers means less custom scripting for signal mapping, freeing up your team to focus on optimizing control logic instead of wrestling with compatibility quirks. In high-throughput processes, this translates to tighter loop control and fewer process deviations, ultimately driving up yield rates and energy efficiency. For sites pushing toward Industry 4.0, the module’s protocol flexibility supports edge analytics without hardware swaps, ensuring your process control infrastructure scales gracefully as data demands grow. The net result? A more agile operation where reliability isn’t a gamble but a built-in certainty, helping you meet SLAs and regulatory audits with confidence.

The GE IC752DPA062 finds its stride in scenarios demanding unyielding critical system uptime, such as water treatment facilities where precise valve sequencing prevents overflows during peak demand. Here, its wide temperature tolerance and noise immunity keep outputs firing accurately amid humid, electrically noisy pump houses, supporting fast data cycles that sync with SCADA for real-time adjustments. In manufacturing assembly lines, particularly automotive or semiconductor fabs, it powers dense arrays of pneumatic actuators under vibration-heavy conditions, ensuring synchronized motion without signal crosstalk that could jam production. Power generation plants leverage it too—for instance, in substation automation where GE IC752DPA062 interfaces with circuit breakers, maintaining high reliability during load shedding events to avoid blackouts. Across these process control environments, the module handles the relentless pace of 24/7 operations, delivering consistent performance that aligns with needs for rapid fault recovery and modular scalability, making it indispensable for engineers prioritizing resilience over reactive fixes.

IC752DPA032 – Compact variant with 8 outputs for space-constrained cabinets

IC752DPA122 – Enhanced model with higher current rating for heavy-duty loads

IC754CSL12CTD – Single-slot carrier base, essential companion for mounting IC752DPA062 in Series 7500 racks

IC752DBR100 – Digital input counterpart for balanced I/O pairs in bidirectional control

IC695DCM200 – PACSystems alternative for VersaMax migrations, offering similar output density

IC752DAA032 – Analog output sibling for hybrid signal needs in mixed architectures

IC754CSL90ECT – Extended carrier with Ethernet integration, upgrade path for networked expansions

IC695ACC310 – Power supply module, pairs with IC752DPA062 for stable backplane feeding

When preparing to deploy the GE IC752DPA062, start by confirming backplane voltage stability—aim for a clean 24 V DC supply within 5% tolerance to avoid initialization glitches. Cross-check slot compatibility in your Series 7500 carrier, ensuring no adjacent modules generate excessive heat that could push beyond the -40°C to +70°C envelope; a quick thermal scan of the panel helps here. Firmware alignment is key—update to the latest via Proficy Machine Edition before powering up, as older versions might limit diagnostic reporting. Grounding integrity matters too; verify shield terminations to earth at a single point to curb induced noise. On the maintenance front, build in quarterly visual inspections of terminal blocks for oxidation, especially in dusty sites, and use the module’s diagnostic port for loopback tests to validate output integrity without dismantling. Monitor power draw trends through the carrier’s logs to spot early signs of channel overload, and schedule annual functional proofs during non-peak hours—simulating faults to confirm failover if redundanced. These steps keep GE IC752DPA062 performing at peak, turning routine upkeep into a low-effort assurance of system health rather than a firefighting exercise.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626