Description

In industrial automation and process control setups—particularly those involving legacy drive systems—engineers often encounter hurdles when integrating auxiliary drives into broader control networks. Legacy AC/DC2000 drives may lack native support for high-speed, deterministic LAN communication, leading to synchronization delays, limited data exchange, or compatibility gaps that compromise system responsiveness and overall efficiency. This becomes critical in applications like turbine auxiliaries, conveyor systems, or multi-drive coordination where precise, real-time feedback between drives and central controllers is essential for maintaining torque control, speed regulation, or fault coordination. The GE IS200ADIIH1AAA directly resolves these issues as an Auxiliary Drive to ISBus Interface Board, enabling seamless bridging of an AC/DC2000 drive to the Innovation Series Bus (ISBus) LAN. It maps integer variables bidirectionally, translating drive-specific signals into a standardized format that aligns with Innovation Series expectations, allowing generic references and feedbacks to mimic full system behavior without extensive custom blockware. In high reliability environments where critical system uptime depends on coordinated drive performance, GE IS200ADIIH1AAA proves vital for retrofits or expansions, minimizing integration risks, reducing latency in command/feedback loops, and supporting scalable architectures without major hardware overhauls. This interface empowers teams to achieve tighter process control, better diagnostics, and smoother operation across distributed industrial automation networks.

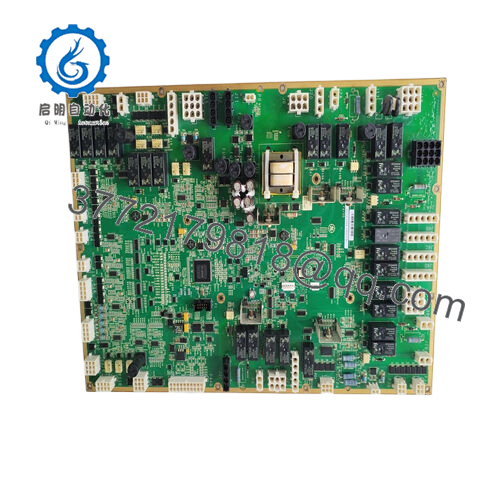

GE IS200ADIIH1AAA functions as a dedicated communication bridge within GE’s Innovation Series and compatible Mark VI architectures, positioned between the AC/DC2000 drive (requiring an LDCC board) and the ISBus Local Area Network. It handles bidirectional data flow using a twisted-pair RJ-45 interface for the ISBus, supporting frame rates programmable from 1 ms to 8 ms to match application demands for fast, deterministic updates. The board processes an integer variable map derived from Innovation Series signal definitions, converting drive parameters—like references, feedbacks, status, and faults—into a format consumable by the controller while relaying commands back to emulate standard drive behavior. Configured via the drive’s local keypad (on DS200LDCCH1A or DS200LDCCG1A) or GE Control System Toolbox software, it loads parameters at power-up or reset without relying on fuses or jumpers. Diagnostic features include seven test points (TP) for probing signals and LED indicators for status monitoring, aiding quick troubleshooting. In multi-node setups, it participates in token-passing or master-slave polling over the ISBus, ensuring reliable propagation of data across the LAN. This placement in the communication layer enhances overall system integration, allowing the drive to appear as a native node while preserving its core functionality, and supports applications needing coordinated control without introducing significant overhead or rewiring.

- IS200ADIIH1AAA

| Specification | Details |

|---|---|

| Model Number | IS200ADIIH1AAA |

| Brand | GE (now Emerson) |

| Type | Auxiliary Drive to ISBus Interface Board |

| Input Voltage | +5 V DC (powered from drive/system) |

| Operating Temp Range | 0°C to 60°C (some sources note 30°C to 65°C) |

| Mounting Style | Chassis/plug-in board (surface mount technology) |

| Dimensions | Approx. 33.0 cm wide x 17.08 cm |

| Weight | Approx. 0.5–1 kg (board only) |

| Interface/Bus | ISBus (twisted pair RJ-45) |

| Compliance | Industrial standards (CE/UL variants possible) |

| Supported Protocols | ISBus LAN (Innovation Series compatible) |

| Typical Power Draw | Low (board-level, ~few watts) |

Choosing GE IS200ADIIH1AAA delivers clear operational advantages in drive-centric automation. Engineered for robust bridging in legacy-to-modern transitions, it ensures long-term performance by providing a stable, low-latency link that keeps drive responses synchronized with controller commands—critical for avoiding torque ripple, overshoot, or desynchronization in coordinated systems. Built-in diagnostics via LEDs and test points allow maintenance teams to pinpoint issues rapidly, such as bus faults or parameter mismatches, reducing troubleshooting time and minimizing unplanned stops. This proactive visibility cuts engineering overhead, as teams spend less effort on custom mapping or signal conditioning.

The board also simplifies upgrades: GE IS200ADIIH1AAA integrates without hardware jumpers or fuses, preserving drive integrity while enabling full ISBus participation. In multi-drive environments, it supports scalable expansion by allowing additional nodes without performance degradation, and its configuration flexibility (via Toolbox or keypad) streamlines deployment across similar assets. The outcome is higher system availability, more predictable behavior under load changes, and easier compliance with process standards—making GE IS200ADIIH1AAA a smart choice for sustaining efficiency in aging but still-vital drive infrastructures.

GE IS200ADIIH1AAA thrives in scenarios demanding precise drive coordination and network integration. In gas or steam turbine auxiliaries within power plants, it connects auxiliary drives to the main control network for synchronized operation during startup, load changes, or emergency trips, supporting critical system uptime where even brief communication lags could affect stability. Heavy process industries like metals rolling mills or paper production use it to link multiple AC/DC2000 drives for coordinated motion control, handling high-speed cycles and load sharing amid electrical noise and vibration. Oil & gas facilities deploy GE IS200ADIIH1AAA in compressor or pump drive systems, ensuring reliable feedback loops for variable speed operation under harsh conditions. These applications share needs for high reliability in continuous-duty environments, fast deterministic communication, and resilience against integration challenges—qualities that position GE IS200ADIIH1AAA as essential for engineers focused on bridging legacy drives into unified process control architectures.

IS200ADIIH1A – Base variant (often referenced interchangeably; check exact revision for compatibility)

DS200LDCCH1A – LDCC board required in AC/DC2000 drives for IS200ADIIH1AAA integration

DS200LDCCG1A – Alternative LDCC processor board for drive-side configuration

IS200ACLEH1A – Application control layer module, complementary for higher-level processing in Innovation Series

IS200AEADH1A – Analog input/output module, pairs for expanded I/O in drive systems

IS200AEBIH1A – Related interface board in Mark VI ecosystems for similar bridging tasks

IS200AEAAH1A – Auxiliary board variant for extended functionality in compatible setups

IS200WEMAH1A – Mark VI-related module, potential upgrade path for modernized turbine controls

Before installing GE IS200ADIIH1AAA, verify the target AC/DC2000 drive includes a compatible LDCC board (e.g., DS200LDCCH1A or DS200LDCCG1A)—without it, the interface won’t function. Confirm power supply delivers stable +5 V DC and check chassis grounding to prevent noise interference on the ISBus. Review firmware/parameters via Toolbox or keypad for alignment with your signal map; mismatches can cause mapping errors. Allow adequate ventilation in the enclosure, as operating temps range from 0°C to 60°C. For maintenance, inspect LEDs regularly for status/fault indications, probe test points during diagnostics if anomalies arise, and examine RJ-45 connections quarterly for wear or looseness—especially in vibration-heavy sites. Periodic parameter backups and functional checks (e.g., command-response loops) during scheduled outages help catch drift early. These practices keep GE IS200ADIIH1AAA reliable, turning preventive care into a low-effort safeguard for network stability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626