Description

In turbine-driven power generation and heavy industrial applications, integrating auxiliary systems—like lube oil pumps, turning gear motors, or hydraulic drives—with the main turbine control architecture often introduces challenges around signal isolation, communication reliability, and fault tolerance. Without a dedicated interface, mismatched protocols or electrical noise can lead to intermittent data loss, delayed responses, or even spurious trips that compromise startup sequences and overall availability. In large gas or steam turbine setups, where the primary controller manages core functions but auxiliary drives operate on separate logic, achieving seamless, deterministic interaction becomes critical for coordinated operation and rapid troubleshooting.

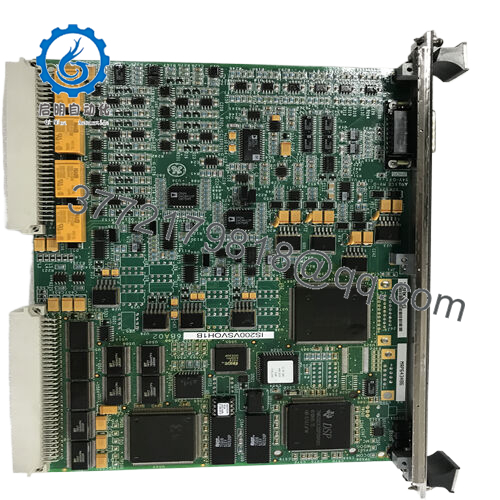

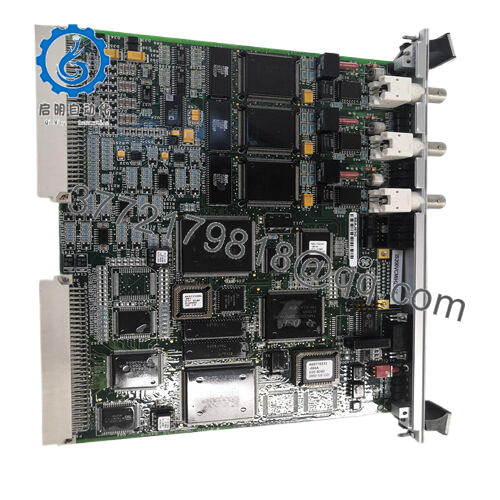

The GE IS200AEAAH1CPR serves as a specialized auxiliary drive to I-Bus interface board within the Speedtronic Mark VI turbine control system, delivering high-reliability bridging for industrial automation and process control in demanding environments. It facilitates robust signal exchange between auxiliary drive controllers and the central I/O network, supporting precise command relay and status feedback while incorporating isolation to maintain signal integrity. This becomes essential in scenarios requiring synchronized auxiliary operations—such as pre-start priming, cooldown turning, or emergency backup drives—where any discontinuity risks extended outages or mechanical stress. By enabling clear diagnostics and noise-immune communication, the GE IS200AEAAH1CPR enhances system stability in turbine process control, particularly when integrating legacy auxiliary equipment into modern distributed architectures.

The GE IS200AEAAH1CPR resides in the I/O interface layer of the Mark VI stack, typically mounted in a VME-style rack alongside control and protection modules. It acts as a gateway, converting and conditioning signals from auxiliary drives for transmission over the proprietary I-Bus network to the main processor, while relaying control outputs back to the drives. This positioning allows direct interaction with terminal boards and IONet channels, ensuring low-latency data flow critical for real-time sequencing.

The board handles discrete inputs/outputs via relays and terminal strips, supporting status monitoring (e.g., run feedback, fault signals) and command issuance (start/stop, speed reference). Built-in isolation and filtering protect against ground loops or EMI common in turbine skids, while diagnostic capabilities feed fault data into the toolbox for quick visualization. In redundant configurations, it can participate in TMR voting schemes for enhanced availability. Configuration occurs through the ControlST toolbox, mapping signals without custom coding. Overall, the GE IS200AEAAH1CPR integrates auxiliary subsystems efficiently into the broader Mark VI architecture, minimizing wiring complexity and supporting scalable expansions.

| Specification | Details |

|---|---|

| Model Number | IS200AEAAH1CPR |

| Brand | GE (Speedtronic Mark VI) |

| Type | Auxiliary Drive to I-Bus Interface Board |

| Input Voltage | 125V DC / 120V AC (field side typical) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | VME rack mount |

| Dimensions | Standard Mark VI board (approx. 26.5 x 10 x 3 cm) |

| Weight | Approx. 1 kg |

| Interface/Bus | Proprietary I-Bus (IONet compatible) |

| Compliance | CE, UL (industrial turbine standards) |

| Supported Protocols | Mark VI internal signaling |

| Typical Power Draw | <50W |

- IS200AEAAH1CPR

Deploying the GE IS200AEAAH1CPR equips your system with a board engineered for resilient performance in turbine auxiliary loops, where consistent signal bridging ensures long-term operational integrity under vibration, temperature swings, and electrical transients. Its relay-based design and isolation features deliver dependable command execution, reducing risks of misoperation that could otherwise lead to prolonged startups or forced outages.

The practical value emerges in integration simplicity—direct compatibility with Mark VI frameworks cuts engineering overhead, allowing straightforward signal mapping and minimal custom interfacing. Maintenance gains come from accessible diagnostics and onboard indicators, enabling technicians to isolate issues rapidly without extensive probing.

In essence, the GE IS200AEAAH1CPR bolsters overall turbine reliability by providing a fault-tolerant link that maintains auxiliary coordination, supporting efficient process control and helping achieve targeted availability metrics in critical power generation setups.

The GE IS200AEAAH1CPR is commonly used in power plants with heavy-duty gas or steam turbines, where auxiliary drives must synchronize precisely during barring, acceleration, or shutdown phases under harsh conditions like high humidity and mechanical shock. In combined-cycle facilities, it ensures reliable integration of hydraulic or motor-driven auxiliaries for continuous uptime.

Oil and gas upstream operations deploy it for compressor train controls, handling fast cycle demands while tolerating explosive atmospheres and remote locations. These process control environments rely on its robust interfacing for critical system uptime during peak loads or transient events.

IS200AEAAH1AAA – Base revision for similar auxiliary interfacing

IS200AEADH1ABA – Related I/O bridge board for expanded discrete signals

IS200ADIIH1AAA – Auxiliary drive direct interface variant

IS200EROCH1ABB – Exciter regulator output complement for generator drives

IS200TBCIH2CAA – Terminal board often paired for field wiring

IS200VTCCH1CBB – Thermocouple input module for auxiliary monitoring

IS200JPDDG1AAA – Power distribution board for auxiliary feeds

IS200DSPXH1DBC – Digital signal processor add-on for enhanced logic

Before inserting the GE IS200AEAAH1CPR, confirm rack slot compatibility and backplane revision to match I-Bus signaling levels—mismatches can cause communication faults. Verify field wiring terminations for proper polarity and shielding, especially on relay outputs, and ensure power sources are stable without excessive ripple. Check toolbox configuration files for pre-loaded mappings to avoid runtime errors.

Maintenance typically includes periodic visual checks of relays for contact wear and terminal tightness, particularly in high-cycle applications. Monitor diagnostic logs via the HMI for any recurring faults, and inspect heat sinks for dust buildup in enclosed cabinets. A biennial functional test—exercising commands through the control sequence—confirms ongoing response integrity without major disassembly.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626