Description

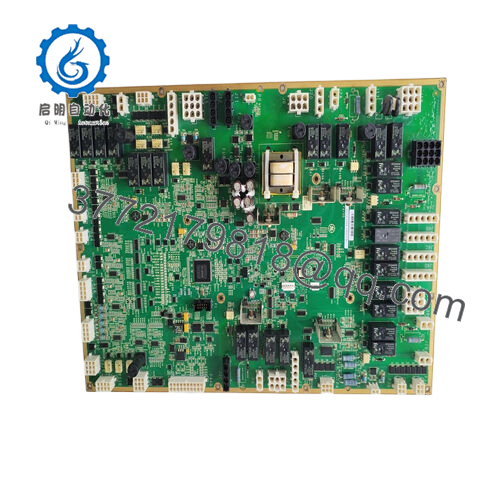

The GE IS200DAMCG1ABB is a Gate Drive Amplifier and Interface Board (often referred to as DAMC board) within GE’s Innovation Series low-voltage drives, part of the Mark VI turbine control ecosystem. It solves key challenges in power electronics for industrial automation by acting as the intermediary between the control rack and Insulated Gate Bipolar Transistors (IGBTs), which are responsible for switching high power in drive systems. In process control and drive applications, signal degradation, improper gate switching, or insufficient amplification can lead to inefficient motor control, overheating, false faults, or system instability—issues exacerbated in noisy environments with variable loads or high switching frequencies. GE IS200DAMCG1ABB is essential in scenarios requiring high reliability for I/O signals, such as when expanding drive phase legs, replacing failed gate drivers in legacy setups, or ensuring precise control in AC/DC drives tied to turbines or motors. It amplifies gate drive signals to reliably turn IGBTs on and off, supporting stable operation in continuous processes where downtime costs are high. This board is particularly valuable for maintaining system integrity in Mark VI-based controls, reducing risks from poor isolation or mismatched interfaces, and enabling scalable configurations without major redesigns.

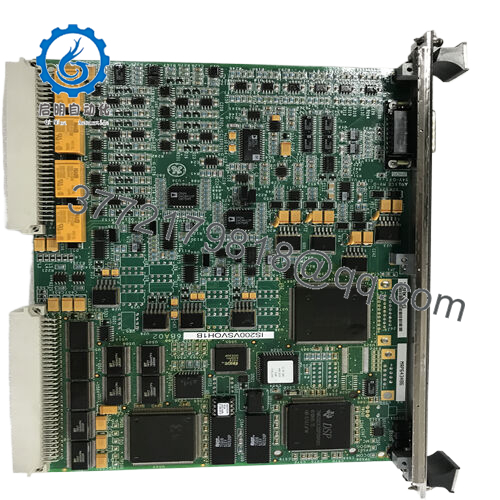

The GE IS200DAMCG1ABB works by receiving low-level gate commands from the control rack (via the IS200BPIA Bridge Personality Interface board) and amplifying them using a +15/-7.5V power supply to drive IGBTs in the power bridge. It handles one IGBT per phase leg, directly connecting to the IGBT’s gate, collector, and emitter terminals for signal transmission while providing isolation through six optocouplers to protect against high voltages and transients. In the automation stack, it’s positioned at the inverter front end in low-voltage Innovation Series drives (often integrated with Mark VIe or EX2100 systems), forming part of the gate drive assembly alongside DAMA and DAMB boards for multi-stage amplification. The board interfaces via ribbon cables (connectors PL and PPL) to the BPIA for control signals and mounts securely on IGBT studs. It includes a microprocessor for monitoring and fault detection, plus four LEDs (DS1/DS2 yellow for UON/UFF and LFF/LON; DS3/DS4 green) to indicate IGBT on/off status per phase leg, aiding real-time diagnostics. While passive in power switching, it ensures transparent signal flow, supports up to 250A frames, and fits into rack-mounted or distributed I/O architectures, enabling redundancy if paired with system-level controls. This integration promotes efficient power conversion in turbine excitation or drive applications, with the GE IS200DAMCG1ABB enhancing overall system modularity and fault tolerance.

- IS200DAMCG1ABB

| Specification | Details |

|---|---|

| Model Number | IS200DAMCG1ABB |

| Brand | GE (General Electric) |

| Type | Gate Drive Amplifier/Interface Board (DAMC variant) |

| Input Voltage | +15/-7.5 VDC (gate drive power supply) |

| Operating Temp Range | Typically -30°C to +85°C (industrial range; confirm with system) |

| Mounting Style | Direct to IGBT studs (front panel of drive) |

| Dimensions | C-shaped and square PCB assembly (exact: not standardized; compact for S800/Innovation fit) |

| Weight | Approx. 0.5 kg |

| Interface/Bus | Ribbon cable to BPIA board; 12 IGBT pins (e.g., COM1/COM2, G1IN/G21N, C1/C2, NC) |

| Compliance | CE, RoHS, potentially ATEX for hazardous areas |

| Supported Protocols | N/A (passive; relies on mated IGBT and control system) |

| Typical Power Draw | Minimal (amplification stage; system-dependent) |

Opting for the GE IS200DAMCG1ABB ensures enhanced gate switching reliability, which is crucial for preventing IGBT failures and maintaining efficient power bridges in long-term operations. Engineered for high-reliability environments, it minimizes signal loss and electrical stress, leading to improved drive efficiency, lower energy consumption, and extended component lifespan—key for reducing maintenance costs in automation plants. The LED status indicators and optocoupler isolation facilitate faster fault resolution, often allowing operators to diagnose issues like upper/lower IGBT faults without disassembly. This board reduces engineering overhead by standardizing terminations in Innovation Series systems, supporting easy swaps during upgrades and ensuring compatibility with Mark VI controls for seamless retrofits or expansions.

In real-world deployments, GE IS200DAMCG1ABB is integral to gas and steam turbine excitation systems using Mark VI controls, terminating gate pulses for IGBT-based inverters in power generation plants to ensure stable excitation and grid synchronization under high loads. It’s also used in low-voltage drive applications within oil & gas or chemical processing for motor control in pumps/compressors, where harsh conditions demand robust amplification for continuous uptime and noise-immune signals. Critical system uptime is maintained in metal rolling mills or renewable energy inverters, handling fast switching cycles and diagnostics to prevent process interruptions.

Compatible or alternative products include:

IS200DAMCG1A – Base non-revisioned version; core gate amplifier for Innovation Series.

IS200DAMCG1ACB – 250A-rated variant with enhanced ampere capacity for heavier phase legs.

IS200DAMEG1A – Gate amplifier/interface for Mark VIe; upgrade for newer e-controls.

IS200DAMAG1B – IGBT gate driver for up to 690V/1700A systems in similar drives.

IS200DAMBG1ABB – Bridge variant for multi-board phase configurations.

DS200FGPAG1AHD – Related Mark VI gate pulse amplifier for exciter applications.

IS200EGPAG1ABD – Exciter-specific gate amplifier with fault reporting enhancements.

Prior to installation of GE IS200DAMCG1ABB, verify compatibility with the Innovation Series drive frame (e.g., 250A) and BPIA interface board; inspect IGBT studs for secure mounting and ensure +15/-7.5V supply is stable. Check ribbon cable integrity (PL/PPL connectors) and apply 13 in-lb torque to captive fasteners/Keps nuts during attachment to avoid loose connections. Confirm firmware on the control rack supports DAMC boards. For maintenance, visually inspect LEDs quarterly for IGBT status (UON/UFF/LON/LFF) and check optocouplers/pins for damage. Annual isolation/continuity tests on terminals help detect wear; clean dust from the board in dirty environments. Replacement is simple: deactivate power, disconnect cables, remove fasteners, install new unit, and verify via diagnostics—ideal for minimizing field time in critical setups.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626