Description

In the roaring heart of gas turbines on offshore platforms, where fuel valves must stroke precisely to match load demands amid salt spray and 50g vibrations, a single servo lag can trigger trips costing millions in lost generation. Steam turbine governors in baseload power plants juggle throttle positions across 100 MW swings, demanding terminal boards that condition LVDT feedback without introducing noise that destabilizes loops. Combined-cycle facilities syncing HRSG dampers to exhaust flows need bulletproof interfaces to hydraulic racks, preventing overspeed events from misread valve gaps. The GE IS200DSVOH1A tackles these turbine control challenges in industrial automation as a DIN-rail mounted servo terminal board for GE Mark VI Speedtronic systems, routing high-fidelity signals from VSVO I/O processors to hydraulic servos for split-second adjustments. Used in industrial automation for turbine governance and protection, it anchors the servo chain in simplex or TMR setups, applicable in control systems from aeroderivatives to frame heavies.

Hydroelectric plants deploy the GE IS200DSVOH1A for wicket gate actuators, filtering ripple from position transducers amid water hammer pulses. Peaking gas units lean on it for inlet guide vanes, ensuring surge-free ramps during grid frequency dips. Refinery steam drives use its isolated terminals to link servo amps, dodging ground shifts from nearby flares. In these high-consequence environments, the board supports ±10 mA to ±120 mA coil drives, turning raw commands into smooth valve motion that sustains 99.98% availability. Operators specify it for retrofit drops into legacy Mark V cabinets, bridging to Mark VIe without rewiring hydraulic manifolds.

Nuclear coolant pumps benefit from the GE IS200DSVOH1A‘s fault-tolerant wiring, monitoring stroke limits to comply with 10 CFR 50 appendices. Compressor stations piping methane leverage it for recycle valves, correlating flows to anti-surge curves. By fortifying servo integrity in industrial automation, it minimizes wear on packing glands, extending overhauls from quarters to years while sharpening response to transients.

Product Introduction & Positioning

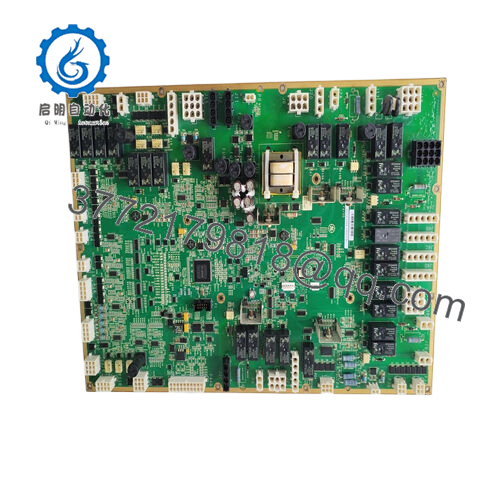

The GE IS200DSVOH1A serves as a rugged DIN-rail terminal board in GE’s Mark VI turbine control platform, interfacing VSVO (simplex) or TSVO (TMR) processor boards with field hydraulic servos via screw terminals for LVDT position feedback and coil excitation. Designed for VME-based I/O packs, it handles up to four independent servo channels, each with dedicated ±15 VDC excitation outputs and signal conditioning to reject common-mode noise up to 250 V. Mounted remotely in servo cabinets, the GE IS200DSVOH1A employs twisted-shielded cabling to span 100m+ without attenuation, feeding demodulated DC levels back to the controller for closed-loop PID tuning.

Positioned for heavy-duty turbine ops, the GE IS200DSVOH1A integrates seamlessly with IONet backbones, supporting diagnostic passthrough for valve signature captures during online washes. Engineers value its plug-compatible headers matching VSVO daughtercards, enabling hot-swap upgrades sans turbine roll. In Mark VI architecture, it sits downstream of QSPI fiber links, isolating high-current servo loops from sensitive VME buses to prevent EMI upset.

For system integrators, the GE IS200DSVOH1A offers TMR variants for voting redundancy, aligning with API 670/616 standards. Jumper-selectable gains tailor it to hydraulic rats from Woodward to Moog, positioning Mark VI as the gold standard for OEM retrofits where servo precision dictates megawatt output.

- IS200DSVOH1A

- IS200DSVOH1A

Key Technical Features & Functional Benefits

Field crews trust the GE IS200DSVOH1A for its galvanic isolation per channel—500 Vrms dielectric withstand keeps turbine trips from false valve-open reads, with low-offset amps (<1 mV) preserving 0.1% stroke resolution across ±2″ LVDTs. DIN-rail clamps endure 2g seismic quakes, while Euro-style barriers accept 14-12 AWG wire torqued to 7 in-lbs for vibration-proof terminations. Onboard fuses (3A fast-act) shield coils from shorts, auto-resetting to speed recovery post-arcs.

Compact at 8″ wide, the GE IS200DSVOH1A DIN-mounts horizontally in IP54 enclosures, drawing zero power as a passive conditioner—ideal for zone 2 hazardous areas with external 24 VDC for excitation relays. Differential inputs reject 60 Hz hum to 80 dB, enabling clean demod from aircraft-grade resolvers in high-vibe zones. Status via VSVO LEDs flags open circuits or excitation faults, cutting troubleshooting from hours to minutes.

Built for 20-year lifecycles, conformal epoxy repels 100% humidity and H2S fumes, with MTBF over 200K hours per MIL-HDBK-217. Euroblock plugs enable pre-fab harnesses, slashing install time in confined turbine decks. Diagnostics loop coil currents back for trend plots, spotting hydraulic leaks via rising drive demands early.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IS200DSVOH1A |

| Brand | GE (Emerson) |

| Type | DIN-Rail Servo Terminal Board |

| Power Supply | Passive (excitation from VSVO) |

| Operating Temperature | -40°C to +70°C |

| Mounting | 35mm DIN-rail (EN 50022) |

| Dimensions | 200 x 75 x 60 mm (L x W x H) |

| Weight | 0.45 kg |

| Interfaces | 4x Servo channels (LVDT + Coil) |

| Certifications | CSA Class I Div 2, ATEX Zone 2 |

| Cooling | Natural convection |

| Environmental Rating | IP20, 0-100% RH |

Related Modules or Compatible Units

VSVO – I/O processor board that plugs directly to GE IS200DSVOH1A for servo drive generation.

TSVO – TMR variant pairing with GE IS200DSVOH1A for voted hydraulic control.

IS200DTAOH1A – Analog output terminal complementing GE IS200DSVOH1A in Mark VI drops.

IS200VSVOH2B – Updated simplex servo board linking to GE IS200DSVOH1A terminals.

UCVV – VME controller coordinating GE IS200DSVOH1A signals in Mark VIe.

DSVO – Legacy simplex terminal superseded by GE IS200DSVOH1A in retrofits.

TRLY – Relay output board for trip solenoids tied to GE IS200DSVOH1A feedback.

Installation Notes & Maintenance Best Practices

Snap the GE IS200DSVOH1A onto DIN-rail 300mm from servos, routing 18 AWG shielded quad to VSVO headers with ferrules stripped 8mm—torque 0.5-0.6 Nm to avoid cold joints. Jumper JP1-4 for ±10/±20/±60/±120 mA per coil per GEH-6421 specs; verify polarity with millivoltmeter pre-power. Ground shield drains single-point to enclosure at <1 ohm, banding cables in ladder trays away from 4160V buswork. Purge enclosure with instrument air if H2S >10 ppm; label TB1-4 per loop sheets for arc-flash audits.

Visuals every 500 hours check for corona blackening on barriers—clean with dry brush, reseating plugs annually for oxide creep. Biannual stroke tests via ToolboxST force 10% demands, logging LVDT linearity (±0.5% span)—recalibrate if hysteresis tops 1%. Swap fuses post-lightning events; log VSVO diagnostics for coil resistance drifts signaling servo oil contamination. Offline, bench-test with function generator to baseline gain before recommissioning.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626