Description

In power plants where turbine generators hum under relentless loads, keeping excitation systems stable becomes mission-critical. Engineers face voltage fluctuations, thermal stresses, and grid demands that can trip entire operations if regulators falter. That’s where the GE IS200ERBPG1A steps in—a rugged backplane module tailored for GE’s EX2100 excitation control systems, used in industrial automation for synchronous generators and motors across utilities, oil and gas facilities, and heavy manufacturing.

Picture a combined-cycle plant in Texas or a hydro station in the Pacific Northwest: sudden load swings demand precise field current control to maintain synchronism. The GE IS200ERBPG1A anchors the exciter regulator stack, linking power bridges, regulators, and diagnostics without signal loss. In marine propulsion setups or steel mill drives, it handles harsh vibrations and EMI interference, ensuring field flashing and voltage regulation hold steady during startups or faults. Operators rely on it for seamless integration into retrofit projects, where older SCR-based exciters meet modern Ethernet Modbus for remote monitoring.

This backplane thrives in environments pushing -30°C to 65°C, supporting applications from 10MW hydro units to 500MW steam turbines. Maintenance teams value its role in minimizing downtime; a single loose connection here could cascade into full outages. Across control systems, the GE IS200ERBPG1A delivers the backbone for scalable excitation, whether scaling from simplex to TMR redundancy or tying into Mark VIe turbine controls. It addresses real pain points like harmonic distortion and overexcitation limits, making it a go-to for integrators upgrading legacy GE setups in power generation.

Product Role in EX2100 Systems

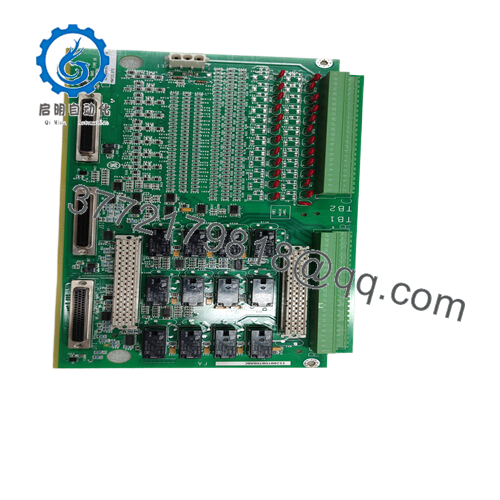

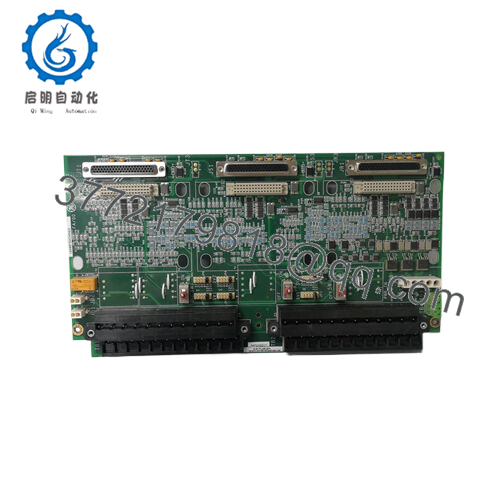

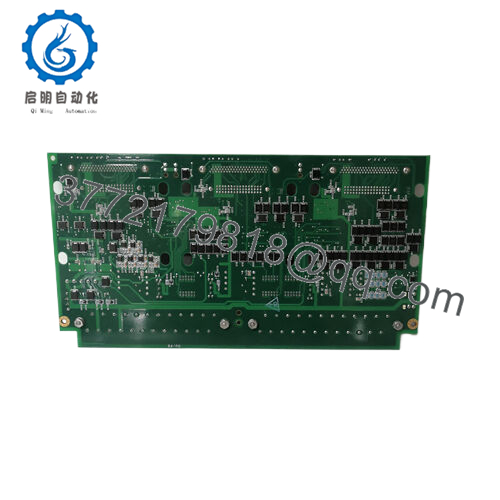

The GE IS200ERBPG1A is an exciter regulator backplane, serving as the central interconnect in GE’s EX2100 series for digital excitation control. It mounts core modules like the ERDD regulator daughterboard and power bridge interfaces, distributing signals and power across the stack.

Designed for standalone or integrated turbine control architectures, it fits neatly into 19-inch racks alongside Mark VI or VIe systems, enabling Ethernet-based communication for HMI oversight. Engineers choose it for its plug-and-play compatibility with GE’s I/O packs and field interfaces, reducing wiring complexity in brownfield upgrades. What sets it apart? Rock-solid signal integrity that supports dual-channel redundancy, vital for SIL-rated safety in critical grids.

Core Strengths

Field technicians swear by the GE IS200ERBPG1A‘s mechanical resilience—its PCB withstands shock up to 20g and vibration per IEC 60068-2, perfect for offshore platforms or seismic zones. Multi-layer gold-fingered connectors ensure low-resistance paths for high-current DC fields, cutting voltage drops that plague lesser boards.

Performance shines in dynamic response: it shuttles analog feedback from PTs and CTs to regulators at microsecond latencies, stabilizing vars under 5% transient dips. Thermal management via convection fins keeps junctions under 85°C, extending MTBF beyond 100,000 hours even in dusty substations. Protocol support spans Modbus TCP and IONet, bridging legacy exciters to SCADA without custom gateways.

Reliability extends to diagnostics—built-in status LEDs and heartbeat signals flag faults early, integrating with ToolboxST for predictive trending. For integrators, its modular footprint swaps into EX2100 cabinets with zero panel cuts, preserving NERC compliance during overhauls

- IS200ERBPG1A

Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IS200ERBPG1A |

| Brand | General Electric (GE) |

| Type | Exciter Regulator Backplane |

| Power Supply | +5V DC, +15V DC (from ERBP supply) |

| Operating Temperature | -30°C to +65°C |

| Mounting | 19-inch rack or cabinet door |

| Dimensions | 10.5 x 5.9 inches (267 x 150 mm) |

| Weight | 1.8 lbs (0.82 kg) |

| Interfaces | Ribbon cable, gold-finger edge connectors, Ethernet Modbus |

| Certifications | CE, UL, IEC 60068 |

| Cooling | Natural convection |

| Environmental Rating | IP20 (suitable for control cabinets) |

Compatible Modules

IS200ERDDG1A – Core regulator daughterboard that plugs directly into the backplane for field control loops.

IS200ERCAG1A – Options card for enhanced communication, stacking atop for Modbus extensions.

IS200EPCCG1A – Power conversion module, linking upstream for bridge drive signals.

IS200ERBPG1B – Updated revision with extra I/O pins for TMR setups.

IS210MVRA_G01 – Relay interface board, pairs for fault isolation in Mark VIe.

IS200TDBT_G01 – Termination board, connects field wiring to backplane headers.

IS420ESWB_G01 – Ethernet switch module for networked diagnostics.

Installation and Maintenance

Before sliding the GE IS200ERBPG1A into a live cabinet, verify 4U rack height clearance and torque standoff screws to 8 in-lbs—loose mounts amplify vibrations in turbine halls. Ground the chassis via dedicated studs to chassis earth, and confirm +5V rails sit steady at 4.75-5.25V; sags here trigger regulator resets. Sequence power-up with bridges last, using a megger on interconnects to spot insulation faults early. Label all ribbon cables by slot to dodge mix-ups during outages.xm-dcs

On the upkeep side, quarterly visuals catch dust buildup on fins—blow it out with dry air to preserve cooling. Cycle diagnostics via HMI every six months, watching for heartbeat drops or CRC errors that signal connector wear. Firmware flashes come painless over Ethernet, but always snapshot configs first. Expect 15-year service life with annual thermal scans; most failures trace to upstream power glitches, so fuse those feeds religiously. Integrators report under 2-hour swaps bayside, keeping MTTR low.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626