Description

The GE IS200HFPAG1ADC plays a vital role in maintaining stable and uninterrupted power delivery within high-demand turbine control environments, where any fluctuation in auxiliary power can compromise critical operations like cooling fan performance or high-frequency signal conditioning. In gas and steam turbine applications using GE’s Speedtronic Mark VI systems, engineers frequently encounter challenges with power integrity—especially when sourcing from variable DC links or isolated AC windings in noisy electrical environments. Voltage drops, harmonic distortion, or insufficient regulation for fan motors and auxiliary circuits can lead to overheating, reduced cooling efficiency, or even forced outages in processes requiring continuous uptime.

These issues become particularly acute in large-scale power generation setups or industrial drives where the control system must handle wide input ranges while delivering precise, isolated outputs for sensitive loads. Without a dedicated, robust power supply board designed for high-frequency operation, systems risk instability during transients, startup sequences, or under heavy load conditions. The GE IS200HFPAG1ADC directly tackles these vulnerabilities as a specialized High-Frequency AC/Fan Power Supply Board within the Mark VI architecture. It accepts flexible inputs and converts them into regulated outputs tailored for fan drives and other high-frequency needs, ensuring consistent performance that keeps turbine auxiliaries reliable and process control intact even in demanding industrial automation scenarios.

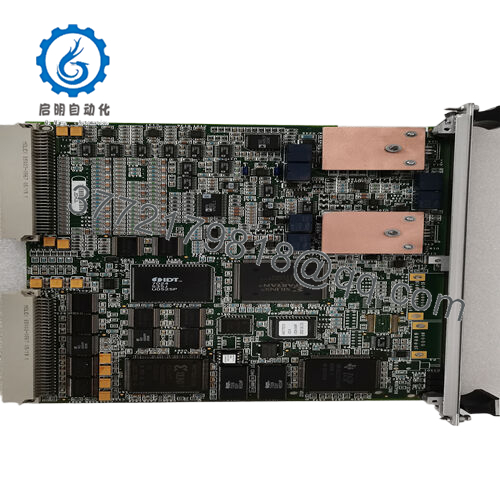

GE IS200HFPAG1ADC serves as a dedicated power conversion and distribution module in GE’s Mark VI Speedtronic turbine control systems, typically installed in control cabinets or near fan enclosures to supply auxiliary power reliably. It accepts inputs from either isolated 230 VAC sources or a broad DC link range (often 230–1000 VDC), then employs a self-oscillating inverter topology to generate multiple outputs: regulated 48 VDC for general use, 48 VAC squarewave at high frequency (around 25 kHz) for efficient fan motor operation, and isolated low-voltage AC (such as 17.7 VAC) for specific auxiliary circuits.

Positioned in the power supply layer of the Mark VI rack or distributed cabinet, this board interfaces via stab-on connectors for inputs (ACF1/ACF2 for AC, DCF1/DCF2 for DC) and multiple plug connectors (up to eight female plugs) for output distribution to fans, control circuits, or other boards. It incorporates protective elements like fuses, a metal oxide varistor, and heat sinks to handle transients and thermal loads without active feedback loops from the main controller—making it a passive yet highly dependable converter in the overall I/O and power architecture. This design allows seamless integration into both new installations and retrofits of Mark VI systems, supporting the high-reliability demands of turbine management while keeping the focus on core control functions rather than power-related troubleshooting.

| Specification | Details |

|---|---|

| Model Number | IS200HFPAG1ADC |

| Brand | GE (General Electric) |

| Type | High-Frequency AC/Fan Power Supply Board |

| Input Voltage | 230 VAC isolated or 230–1000 VDC |

| Operating Temp Range | Typically -20°C to +60°C (Mark VI standard; confirm with cabinet environment) |

| Mounting Style | PCB in plastic carrier, rack or cabinet mounted (near fan enclosure or board rack) |

| Dimensions | Approx. 26 cm × 10 cm × 8 cm |

| Weight | Approx. 0.3 kg |

| Interface/Bus | Stab-on connectors (4) for input; female plug connectors (8) for outputs |

| Compliance | CE compliant (typical for Mark VI series); industrial ruggedized design |

| Supported Protocols | N/A (power supply; integrates with Mark VI IONet/Ethernet for system-level monitoring) |

| Typical Power Draw | Dependent on load; efficient high-frequency conversion minimizes losses |

- IS200HFPAG1ADC

Selecting the GE IS200HFPAG1ADC brings measurable improvements to turbine control reliability by delivering clean, regulated power that keeps cooling fans and auxiliary circuits operating at peak efficiency. Engineered for the rigors of high-frequency switching, it maintains stable outputs across wide input variations, which helps prevent thermal excursions in critical components and supports extended mean time between failures in continuous-run applications.

This board reduces engineering overhead during commissioning and expansions, as its flexible input acceptance simplifies sourcing from existing DC links or AC supplies without additional converters. In practice, it contributes to smoother startups, fewer nuisance trips from power anomalies, and more predictable maintenance cycles—allowing teams to allocate resources toward optimizing turbine performance rather than chasing intermittent power issues. Over the long term, its protective features and thermal design ensure consistent operation in harsh environments, lowering overall lifecycle costs in mission-critical setups.

GE IS200HFPAG1ADC is commonly deployed in gas and steam turbine facilities within power generation, including combined-cycle plants, peaking stations, and industrial cogeneration sites where Mark VI controls manage startup, speed, load, and protection functions. In these environments, it powers essential fans for cabinet cooling or exciter auxiliaries, ensuring continuous uptime under extreme conditions like high ambient temperatures, electrical noise from generators, or vibration from rotating equipment.

It’s also found in heavy-duty drive systems for compressors or pumps in oil & gas and petrochemical processes, where fast response to load changes demands unwavering auxiliary power. Across these uses, GE IS200HFPAG1ADC upholds critical system uptime by providing the stable high-frequency power needed for reliable fan operation and signal integrity in process control environments.

For related options within the Mark VI family or similar power supply roles, consider these:

IS200HFPAG1AAA – Earlier revision in the same HF AC supply series, often interchangeable for standard applications.

IS200HFPAG1ABB – Variant with potential minor component updates for improved transient handling.

IS200HFPAG1ADB – Closely related high-frequency power supply board, suitable as a direct alternative in many Mark VI configurations.

IS200HFPAG2ADC – Higher-spec version in the series for applications needing enhanced capacity or different output configurations.

IS200HFPAG1A – Base model without the full revision suffix, compatible in legacy or less demanding setups.

DS200DCFBG1 – Related DC feedback/power board in Speedtronic systems for broader power management needs.

IS200EGPAG1 – Excitation-related power board for integration in turbine excitation controls.

IS215UCVGH – Processor/control board that pairs with power supplies like this in Mark VI racks.

Before installing GE IS200HFPAG1ADC, confirm input source compatibility (AC isolated windings or DC link voltage within rated range) and verify connector pinouts match your cabinet wiring diagram to avoid misconnection. Ensure adequate ventilation around the heat sinks, as mounting near fans or in enclosed racks affects thermal performance—check for sufficient clearance and airflow per Mark VI guidelines. Review the host system’s firmware and any associated power distribution modules for alignment, though this board requires no configuration itself.

Ongoing maintenance involves periodic visual inspections of connectors for corrosion or looseness, especially in humid or dusty environments, and checking heat sink cleanliness to sustain efficient dissipation. Monitor system LEDs or Toolbox diagnostics for any power-related faults that could trace to the board, and test output voltages during scheduled outages using a multimeter on key plugs. These straightforward checks align with typical Mark VI preventive routines, helping sustain long-term stability with minimal intervention.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626