Description

The GE IS200TBCIH1CCD addresses a fundamental requirement in turbine control architectures: providing secure, noise-immune termination for discrete contact signals from field devices while preserving electrical isolation to prevent ground loops or cross-talk that could destabilize critical protection and sequencing logic. In GE Speedtronic Mark VI (and compatible Mark VIe) systems, operators and engineers often struggle with unreliable contact inputs—dry switches, limit switches, or relay contacts—that feed into overspeed, trip, startup permissive, or emergency shutdown circuits. Environmental noise, long cable runs, varying ground potentials across distributed equipment, or inadequate isolation can introduce false signals, leading to nuisance trips, delayed startups, or missed protective actions in high-stakes power generation or mechanical drive applications.

These vulnerabilities are amplified in large turbines where uptime is measured in months of continuous operation, and any spurious input can trigger costly forced outages or safety interlocks. The GE IS200TBCIH1CCD resolves this by functioning as a dedicated Contact Input Terminal Board with Group Isolation, engineered specifically for the Mark VI series (and extendable to Mark VIe via compatible I/O packs). It handles 24 discrete dry contact inputs through robust barrier-type terminal blocks, applies a floating excitation voltage (typically nominal 125 VDC) to ensure reliable wetting current without relying on field-supplied power, and groups inputs with isolation to maintain signal integrity in electrically harsh industrial automation settings. This approach keeps the focus on precise process control and turbine protection rather than wrestling with intermittent contact reliability.

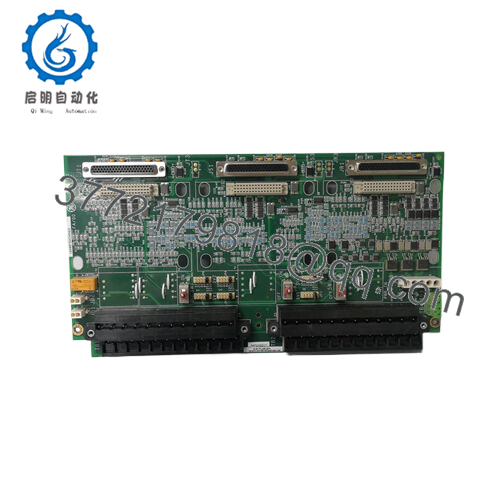

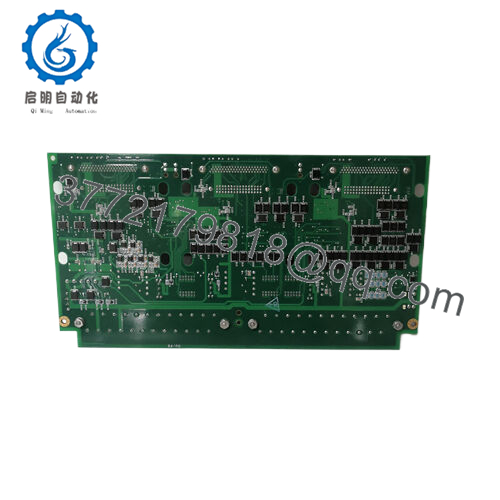

GE IS200TBCIH1CCD acts as the field-side interface in GE’s Mark VI Speedtronic turbine control ecosystem, typically mounted in I/O terminal cabinets or racks adjacent to the main processor or I/O packs. It features two sets of 12-point barrier terminal blocks (TB1 and TB2) for wiring up to 24 contact inputs, routing these signals to onboard conditioning circuitry that includes group isolation barriers. The board supplies a floating excitation source to the contacts, detecting closed/open states and passing conditioned logic signals via multiple connectors (often three main ports plus auxiliary) to interfacing I/O packs such as VTCC/VCRC in Mark VI simplex/TMR configurations or PDIA packs in Mark VIe setups.

In the automation stack, it sits at the boundary between field wiring and the control system’s discrete input processing, isolating groups of channels to minimize propagation of faults or noise across inputs. This passive termination design requires no active power beyond the excitation supply and integrates seamlessly into both new Mark VI installations and upgrades to Mark VIe, supporting redundant or simplex architectures without reconfiguration. The layout promotes organized cabling, reduces wiring density issues in crowded panels, and aligns with the high-reliability demands of turbine sequencing, where fast, dependable detection of contact changes ensures accurate response to permissive, protective, or status signals from the field.

| Specification | Details |

|---|---|

| Model Number | IS200TBCIH1CCD |

| Brand | GE (General Electric) |

| Type | Contact Input Terminal Board with Group Isolation |

| Input Voltage | Nominal 125 VDC floating excitation (for contact wetting; field contacts dry) |

| Operating Temp Range | Typically -20°C to +60°C (Mark VI standard; cabinet-dependent) |

| Mounting Style | Panel or DIN rail in I/O cabinet (PCB with terminal blocks) |

| Dimensions | Approx. 33 cm × 10.2 cm × 4.8 cm |

| Weight | Approx. 0.5–1 kg |

| Interface/Bus | Terminal blocks (24 points via two 12-point barriers); connectors to VTCC/PDIA I/O packs |

| Compliance | Industrial ruggedized; CE typical for Mark VI series |

| Supported Protocols | N/A (discrete input termination; supports Mark VI/Mark VIe IONet or internal bus via pack) |

| Typical Power Draw | Low (excitation supply only; dependent on contact current draw) |

Opting for the GE IS200TBCIH1CCD yields strong operational advantages in turbine-centric environments by delivering consistent, isolated contact detection that minimizes false positives and enhances protective system trustworthiness. Its group isolation design safeguards against common-mode disturbances, ensuring that a fault on one input group doesn’t cascade to others, which supports higher overall system availability and compliance with safety standards in critical applications.

The board streamlines installation and troubleshooting with clear terminal labeling and robust mechanical connections that resist vibration and thermal cycling common in power plants. Over time, this reduces maintenance burdens—fewer spurious alarms mean less operator intervention—and bolsters long-term performance by keeping discrete logic accurate during transients or grid disturbances. In essence, GE IS200TBCIH1CCD helps shift engineering effort from signal validation to optimizing turbine efficiency and reliability.

GE IS200TBCIH1CCD is routinely applied in gas and steam turbine facilities for power generation, including combined-cycle plants, base-load stations, and peaking units where Mark VI controls oversee sequencing, protection, and monitoring. In these setups, it terminates contacts from emergency pushbuttons, breaker status, lube oil pressure switches, or flame detector relays, upholding critical system uptime amid high temperatures, electromagnetic interference, and mechanical vibration.

It’s also prevalent in industrial mechanical drive applications like compressors in oil & gas or petrochemical processing, where reliable discrete inputs are essential for safe startup permissives and trip logic in process control environments. Across these deployments, GE IS200TBCIH1CCD ensures dependable signal fidelity for fast-response protection and control loops.

- IS200TBCIH1CCD

For related options within the Mark VI / Mark VIe family or similar termination roles, consider these:

IS200TBCIH1C – Base or closely related revision of the contact input terminal board, often functionally equivalent in standard Mark VI applications.

IS200TBCIH1B – Earlier variant with similar 24-channel group isolation, suitable for legacy Mark VI migrations.

IS200TBCIH2C – Higher-density or alternative grouping configuration for expanded discrete input needs.

IS200TBCIH1BBC – Revision with potential enhancements in component layout or isolation for specific Mark VI setups.

IS200TBCIS2C – Discrete input terminal board variant focused on different contact handling or compatibility.

IS220PDIAH1B – Mark VIe I/O pack that plugs directly into compatible TBCI boards for distributed input processing.

IS200TBAIH1C – Analog input terminal board counterpart for mixed I/O in the same Mark VI rack.

IS200TBDTH1A – Discrete terminal board for thermocouple or other specialized inputs in turbine controls.

Before installing GE IS200TBCIH1CCD, cross-check compatibility with your Mark VI or Mark VIe I/O pack (VTCC, VCRC, or PDIA) and verify excitation voltage matches system requirements to avoid wetting current issues. Confirm terminal block wiring against the GE wiring diagram for correct grouping and polarity, and allow sufficient panel space for heat dissipation and cable bending radius—especially with armored field cables. Ensure the cabinet grounding scheme aligns to leverage the floating excitation effectively.

For ongoing maintenance, perform visual inspections of terminals during outages to check for loose wires, corrosion, or dust buildup that could affect contact reliability. Use system diagnostics (via Toolbox or CIMPLICITY) to monitor input status for anomalies, and periodically verify excitation voltage at the board with a multimeter. Cleaning contacts and retorqueing screws annually fits standard preventive schedules for Mark VI hardware, helping sustain signal accuracy with routine effort.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626