Description

Real-World Use & Application Scenarios

Where is this product used and why?

In GE Mark VI-based turbine control installations, the IS200TREGH1BDC serves as the dedicated terminal board for emergency trip signaling. It interfaces with protection relays, trip solenoids, and shutdown circuits to guarantee that a fault event triggers a prompt, unambiguous turbine trip. Applications include power generation facilities, large industrial gas turbines, and combined-cycle plants where fast, reliable shutdown capability is mandatory for safety and equipment protection. The board’s function is integral to the overall fault-threshold architecture, enabling safe disconnection of fuel or ignition sources under fault conditions. The model variant is selected to match the specific wiring topology and interlock requirements of the plant, and engineers rely on its documented compatibility with the Mark VI backplane and associated trip logic. This configuration is commonly referenced in procurement and maintenance documentation for emergency trip substations and turbine control cabinets.

Product Introduction & Positioning

What it is, where it fits, and why it matters

The IS200TREGH1BDC is a turbine emergency trip termination board that complements GE’s Mark VI turbine control family. It sits in the protection and control assembly, receiving signals from protective logic and delivering decisive trip commands to the turbine’s shutdown circuits. The module is designed to work in concert with related terminal boards and protection I/O to ensure a coherent, fail-safe trip sequence. For engineers, this board provides a clear, modular approach to emergency protection, enabling straightforward wiring, diagnostics, and maintenance within a familiar GE turbine control ecosystem.

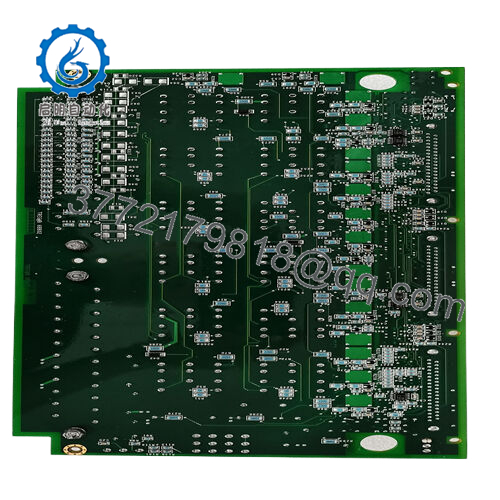

- IS200TREGH1BDC

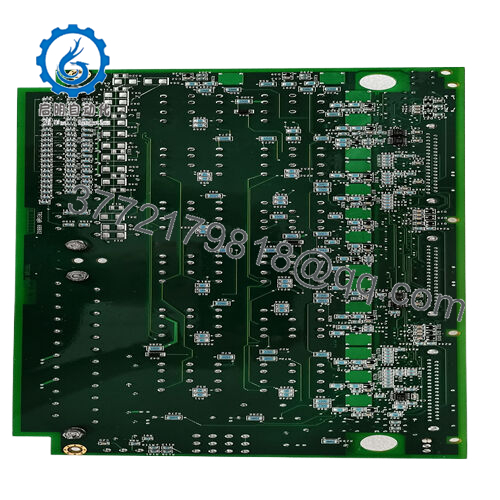

- IS200TREGH1BDC

Key Technical Features & Functional Benefits

Performance, reliability, and integration

The IS200TREGH1BDC is engineered for rapid interlock action, providing deterministic response times essential for safe turbine shutdowns. Its wiring topology supports reliable interconnection with trip relays and safety circuits, while its rugged construction suits the demanding industrial environment of turbine halls. The module’s integration with Mark VI tooling enables streamlined configuration, testing, and fault analysis, helping commissioning engineers validate trip paths and interlocks quickly. By ensuring a robust, well-documented trip termination path, this board contributes to overall plant safety, compliance with protective standards, and reliable shutdown performance when protection logic triggers.

Installation Notes & Maintenance Best Practices

Two concise paragraphs

Prior to installation, verify the exact wiring diagram for the emergency trip path and confirm compatibility with the existing trip logic and interlocks in the Mark VI rack. Ensure secure mounting in the protection cabinet, proper grounding, and clear labeling of trip channels to support safe maintenance and swift fault diagnosis. During commissioning, test the trip signal path end-to-end, including verification of hold-in, interlock checks, and gapping with related output controls. Schedule periodic inspections for terminal integrity, connector cleanliness, and potential corrosion in the high-current path, and align any firmware or configuration baselines with GE’s service bulletins to maintain deterministic performance over the asset’s lifecycle.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626