Description

The GE IS200TTURH1CFD (often cross-referenced as IS230TNTRH1C) serves as a specialized primary trip interface in GE Speedtronic Mark VIe turbine control systems, where dependable, fast-acting protection logic is essential to safeguard rotating equipment from overspeed, excessive vibration, loss of flame, or other hazardous conditions. In gas and steam turbine applications, engineers regularly contend with the need for redundant, voted trip paths that respond in milliseconds to prevent catastrophic failures while avoiding unnecessary shutdowns that disrupt power output or process continuity. Spurious trips from noise, contact bounce, or wiring faults can erode operator confidence and lead to production losses, while delayed or missed trips pose serious safety and asset risks in high-energy environments.

These challenges intensify in TMR (Triple Modular Redundant) configurations common to critical turbines, where multiple sensors and logic paths must converge reliably on trip decisions without introducing single points of failure. The GE IS200TTURH1CFD tackles this by providing a turbine-specific primary trip terminal board that handles key protection inputs—such as emergency trip contacts, overspeed signals, and permissive relays—with robust termination, isolation, and relay-based output for breaker or fuel valve actuation. It ensures high-reliability signal routing in noisy industrial automation settings, supporting the core goal of maintaining turbine integrity and operational availability without compromising protection speed or fault tolerance.

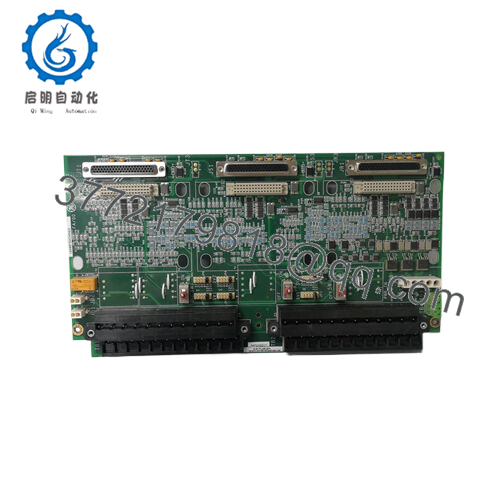

GE IS200TTURH1CFD functions as the field termination and primary relay interface layer in Mark VIe Speedtronic architectures, typically installed in dedicated protection I/O cabinets or integrated into the main control rack alongside associated I/O packs like PTUR or VTUR equivalents in the Mark VIe ecosystem. It features barrier-style terminal blocks for secure connection of discrete protection signals (e.g., dry contacts from overspeed relays, emergency stop buttons, or flame scanner status), along with onboard relays that execute voted trip commands—often requiring coordinated closure across channels in TMR setups to energize the main breaker (52G) or initiate fuel cutoff.

Positioned at the boundary between field wiring and the control system’s protection logic, this board supplies excitation where needed, conditions signals for noise immunity, and routes outputs via multiple connectors to the interfacing processor or I/O packs for voting and execution. Its design emphasizes galvanic isolation and rugged construction to handle transients common in generator proximity, while supporting simplex or redundant configurations through jumper settings or pack coordination. In practice, GE IS200TTURH1CFD integrates cleanly into Mark VIe racks, enabling straightforward wiring for critical trip paths and aligning with the distributed I/O approach that keeps protection logic close to the turbine while leveraging IONet for higher-level diagnostics and HMI integration.

- IS200TTURH1CFD

| Specification | Details |

|---|---|

| Model Number | IS200TTURH1CFD |

| Brand | GE (General Electric) |

| Type | Turbine Specific Primary Trip Terminal Board |

| Input Voltage | Nominal 125 VDC (for excitation/relay coils; field contacts dry) |

| Operating Temp Range | -30°C to +65°C (typical Mark VIe; cabinet environment dependent) |

| Mounting Style | Panel-mounted in I/O cabinet (PCB with terminal blocks and connectors) |

| Dimensions | Approx. 33 cm (H) × 17.8 cm (W) × variable depth (standard Mark VIe form factor) |

| Weight | Approx. 0.8–1.2 kg |

| Interface/Bus | Barrier terminal blocks for inputs; multiple connectors to PTUR/PDIA packs or equivalent |

| Compliance | Industrial ruggedized; CE typical for Mark VIe series; conformal coating variants available |

| Supported Protocols | N/A (discrete protection termination; supports Mark VIe IONet via packs) |

| Typical Power Draw | Low (relay and excitation dependent; minimal active consumption) |

Choosing GE IS200TTURH1CFD delivers critical advantages in turbine protection by providing a hardened, relay-driven trip interface that ensures deterministic response times and high fault coverage in redundant architectures. Its isolation and robust termination minimize noise-induced false trips, fostering greater system confidence and reducing forced outage frequency in continuous-operation plants.

The board simplifies retrofits and expansions in existing Mark VIe setups, with organized terminal access and compatibility that cuts commissioning time and wiring errors. Long-term, it supports consistent protective performance through vibration-resistant design and thermal tolerance, helping teams maintain SIL-level integrity without frequent interventions. This contributes to lower risk exposure, extended asset life, and more efficient allocation of maintenance resources toward proactive turbine optimization.

GE IS200TTURH1CFD is widely deployed in gas turbine combined-cycle plants, simple-cycle peaking facilities, and steam turbine generator sets within utility and industrial power generation, where Mark VIe systems manage comprehensive protection during startup, synchronization, and full-load operation. In these environments, it terminates and relays signals for primary overspeed, emergency trip, and breaker control loops, upholding critical system uptime amid electrical noise, high vibration, and thermal extremes typical of turbine halls.

It’s also common in heavy industrial drives for compressors or mechanical equipment in oil & gas and petrochemical sectors, supporting fast, reliable trip execution in process control environments that demand zero-tolerance for overspeed or mechanical faults. Across applications, GE IS200TTURH1CFD reinforces dependable protection pathways essential for safe, uninterrupted turbine performance.

For related options within the Mark VIe family or similar protection/termination roles, consider these:

IS200TTURH1B – Earlier or base revision of the turbine terminal board, often interchangeable in legacy Mark VI setups.

IS200TTURH1CFD – Current variant (this model) with potential updates for Mark VIe compatibility and enhanced isolation.

IS200TTURH1C – Closely related primary trip board, suitable as a direct substitute in many configurations.

IS230TNTRH1C – Equivalent/alternate part number for the same turbine-specific primary trip functionality.

IS200TRELH1A – Emergency trip relay board for complementary protection logic in Mark VIe.

IS200TRESH1B – Overspeed protection board that pairs with TTUR for comprehensive trip coverage.

IS200TRLYH1BDC – Contact output terminal board for expanded relay-driven actions in turbine systems.

IS200TBAIH1C – Analog input terminal board for integrating process signals alongside discrete protection.

Before installing GE IS200TTURH1CFD, verify exact compatibility with your Mark VIe I/O pack (e.g., PTUR or equivalent) and confirm excitation/relay voltage aligns with system design to prevent actuation issues. Review wiring diagrams for correct terminal assignments on protection inputs and output relays, ensuring proper grouping for TMR voting if applicable. Provide adequate cabinet ventilation and grounding to support thermal and noise performance—check clearances for field cable entry and relay access during panel layout.

Ongoing maintenance should include periodic checks of terminal torque, relay contact resistance (using a multimeter during outages), and visual inspection for dust or corrosion on connectors. Leverage Mark VIe Toolbox diagnostics to monitor trip status and relay health, and retorque screws or clean terminals annually as part of standard preventive routines. These measures help preserve fast, reliable trip response with practical effort aligned to turbine outage schedules.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626