Description

In turbine control systems for gas, steam, and aeroderivative applications, accurate monitoring of mechanical vibration is essential for detecting imbalance, misalignment, bearing wear, or other anomalies that can lead to catastrophic failures if unchecked. Without robust, noise-immune interfaces for vibration sensors, signals from proximitors, velomitors, accelerometers, or seismic probes can degrade over long cable runs, suffer from EMI interference, or lack the excitation needed for reliable operation—resulting in false alarms, missed detections, or unnecessary shutdowns. In high-vibration environments like turbine skids, where continuous monitoring supports predictive maintenance and protects against excessive mechanical stress, a dedicated terminal board with integrated suppression and diagnostics becomes indispensable for maintaining data integrity and system availability.

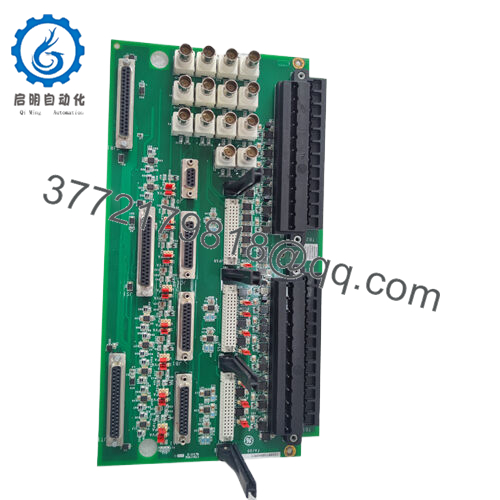

The GE IS200TVBAH2ACC delivers this capability as a vibration input terminal board in the Speedtronic Mark VIe turbine control platform, providing high-reliability signal interfacing for industrial automation and process control. It supports direct connection of up to 14 vibration channels plus a Keyphasor reference, accommodating Proximitor, Velomitor, accelerometer, and seismic probes with onboard -24V excitation and EMI protection per channel. This makes the GE IS200TVBAH2ACC critical in applications demanding precise, real-time vibration data—such as bearing protection, rotor dynamics analysis, or compliance with API standards—where clean I/O signals enable advanced alarming and trending. By incorporating BNC outputs for external monitors and diagnostics for out-of-range conditions, the GE IS200TVBAH2ACC ensures proactive fault detection in harsh process control environments, minimizing risks associated with sensor noise or power inconsistencies.

The GE IS200TVBAH2ACC operates in the field termination layer of the Mark VIe distributed control architecture, typically mounted in auxiliary panels and cabled to PVIB or YVIB I/O packs for signal processing. It conditions raw sensor outputs—providing excitation, filtering transients, and suppressing interference—before passing data over dual RJ-45 connectors to the I/O pack for integration into the control logic. Positioned downstream from probes but upstream from the processor, it handles multiple probe types without external signal conditioners, supporting configurable channels via the toolbox software.

The board includes two barrier-type terminal blocks for field wiring (up to #12 AWG) and shield attachments, plus optional 9/25-pin connectors for parallel feeding to systems like Bently Nevada 3500 monitors. Diagnostics are comprehensive: the I/O pack queries an onboard ID chip for board identification and monitors voltages for faults, relaying alerts to the HMI. While simplex in nature, it fits seamlessly into TMR setups when fanned across redundant packs. The GE IS200TVBAH2ACC emphasizes straightforward integration, with BNC outputs per channel for portable analyzers and robust isolation ensuring deterministic vibration data flow in fast-update loops.

- IS200TVBAH2ACC

- IS200TVBAH2ACC

| Specification | Details |

|---|---|

| Model Number | IS200TVBAH2ACC |

| Brand | GE (Speedtronic Mark VIe) |

| Type | Vibration Input Terminal Board |

| Input Voltage | 28V DC (typical, from power distribution) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | Panel mount (screw or DIN-rail compatible) |

| Dimensions | Approx. 263 × 58 × 28 mm |

| Weight | Approx. 0.4 kg |

| Interface/Bus | Dual RJ-45 to PVIB/YVIB I/O pack |

| Compliance | CE, UL, hazardous location options |

| Supported Protocols | Mark VIe internal I/O signaling |

| Typical Power Draw | Low (board-level, <20W) |

Implementing the GE IS200TVBAH2ACC provides a terminal board engineered for sustained accuracy in vibration monitoring loops, where consistent signal conditioning and excitation ensure long-term performance despite elevated temperatures, humidity, or mechanical shock. Its EMI shielding and suppression features deliver dependable data in electrically noisy turbine bays, reducing nuisance trips and supporting precise trending over years of operation.

The board’s design facilitates integration ease—direct probe compatibility and standard connectors minimize engineering overhead during upgrades or expansions, while parallel outputs avoid conflicts with existing monitors. Maintenance efficiency improves through built-in diagnostics and BNC access, allowing quick verification without disconnecting field wires.

Fundamentally, the GE IS200TVBAH2ACC enhances turbine reliability by supplying clean, actionable vibration inputs that enable early anomaly detection, optimize maintenance scheduling, and contribute to extended equipment life in critical process control applications.

The GE IS200TVBAH2ACC is routinely deployed in power generation plants operating heavy-duty gas or steam turbines, where multiple bearing and casing probes must deliver accurate data under intense vibration and thermal stress for continuous uptime. In aeroderivative packages or industrial compressors, it supports shaft proximity and seismic monitoring for rapid transient response.

Oil and gas production facilities use it for turbomachinery protection in harsh conditions, providing the high-resolution inputs needed for fast data cycles in predictive analytics. These process control environments depend on its robust interfacing for critical system uptime during high-load operations or remote deployments.

IS200TVBAH2ABA – Earlier revision with similar vibration channel support

IS200TVBAH2AAA – Base model for standard applications

IS200VVIBH1CAB – Vibration processor board (VVIB) often paired for signal processing

IS200TVIBH2BCC – Larger vibration termination board for expanded inputs

IS200TBCIH2CAA – Contact input terminal board for trip signals

IS200TSVOH1B – Servo terminal board for valve positioning integration

IS200VPROH1B – Protection module complement for overspeed/vibration trips

IS200VAICH1D – Analog input board for additional sensor channels

Before wiring the GE IS200TVBAH2ACC, confirm probe types match channel capabilities and verify excitation requirements—use jumpers if needed for specific configurations. Ensure stable 28V DC distribution with proper grounding to prevent noise coupling, and leave clearance for terminal access and heat dissipation in the panel.

Ongoing maintenance centers on periodic terminal tightness checks and shield continuity, especially in corrosive or vibrating settings. Review toolbox diagnostics regularly for voltage anomalies or ID faults, and use BNC ports for spot-checks with a portable analyzer during outages. An annual probe calibration loop test—comparing readings across channels—helps validate overall integrity without extensive downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626