Description

Many products have not yet been launched, please contact us for more product information.

We have 16 shared warehouses worldwide, so please understand that sometimes it may take several hours to accurately respond to you. Of course, we will reply to your question as soon as possible.

In turbine control rooms where every thermocouple reading, pressure transducer signal, and vibration sensor feed must arrive at the controller without distortion or delay, boards like the GE IS200VAICH1CBB quietly handle the heavy lifting. Operators at gas-fired power plants, steam turbine halls, and offshore compressor platforms rely on it to capture analog data from field devices amid the hum of rotating machinery and electrical transients. This VME-based analog input module is deployed in GE Speedtronic Mark VI control systems, processing signals that drive protective trips, performance optimization, and condition monitoring—tasks where a single missed value could mean downtime or worse. Engineers turn to it in environments demanding precise multiplexing of multiple inputs, such as generator bays or boiler feedwater controls, where it ties field wiring to the system’s digital backbone

Picture a heavy-duty gas turbine startup sequence: the GE IS200VAICH1CBB gathers temperatures from exhaust stacks, compressor inlets, and bearing housings, ensuring the Mark VI controller has clean, timely data for sequencing valves and firing rates. It’s used in industrial automation setups from petrochemical refineries to utility peaking plants, where harsh cabinet conditions—vibration, dust, and 24/7 loads—test hardware limits. Applicable in control systems handling everything from hydraulic servo positions to flame detector outputs, this board supports scalable I/O architectures that grow with plant expansions. Maintenance crews value its role in diagnostics too, as it flags open circuits or out-of-range signals before they cascade into faults.

Beyond core turbine applications, the GE IS200VAICH1CBB appears in balance-of-plant skids for pumps, fans, and heat recovery steam generators, where integrating legacy 4-20 mA loops with modern DCS demands reliable signal conditioning. In these scenarios, it bridges the gap between rugged field instruments and high-speed VME busses, enabling predictive analytics on asset health without constant recalibration. For integrators facing retrofit projects, its compatibility with Mark VI racks makes it a go-to for upgrading older analog front-ends while preserving system validation.

Product Introduction & Positioning

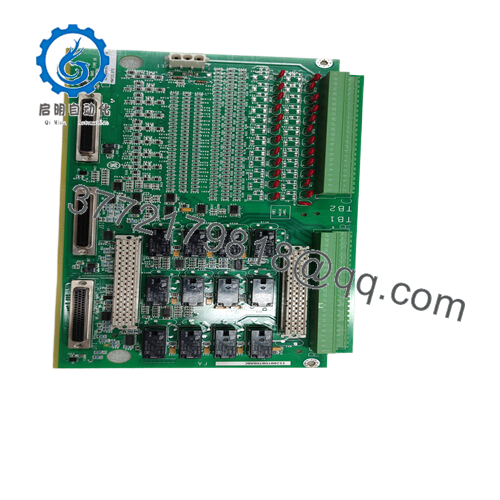

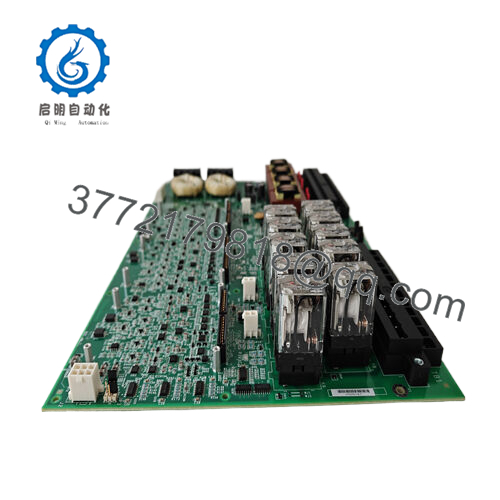

The GE IS200VAICH1CBB serves as a VME analog input/output card within General Electric’s Speedtronic Mark VI turbine control platform, occupying a dual-slot position in standard VME racks. It processes up to 10 differential analog inputs alongside 2 analog outputs, multiplexing field signals like voltages, currents, and RTDs into the controller’s data stream for real-time processing. Sitting at the I/O layer of the Mark VI architecture, it connects via dedicated terminal boards (such as TBAI variants), converting raw transducer data into digital formats that feed protection logic, sequencing algorithms, and HMI displays

In a full Mark VI setup, the GE IS200VAICH1CBB integrates with core controllers, power supplies, and communication modules, forming a fault-tolerant I/O subsystem that supports simplex or redundant configurations. Its role extends to handling high-impedance signals with built-in isolation, preventing ground loops from compromising accuracy in multi-cabinet installations. This makes it essential for turbine governors, where precise analog feedback loops adjust fuel flow or steam admission based on live measurements.

What sets the GE IS200VAICH1CBB apart for turbine engineers is its drop-in compatibility across Mark VI revisions, minimizing reconfiguration during upgrades or spares replacement. Integrators appreciate how it pairs with GE’s Toolbox software for signal mapping and diagnostics, streamlining commissioning in fast-track projects. Positioned as a workhorse for demanding analog-heavy applications, it delivers the stability and channel density that keep critical processes online without introducing integration headaches.

Key Technical Features & Functional Benefits

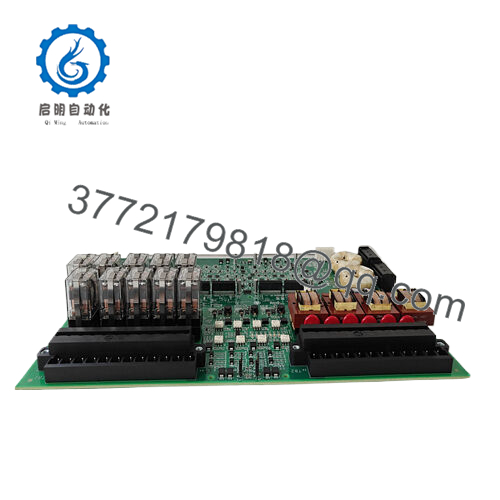

Handling diverse field signals starts with the GE IS200VAICH1CBB‘s 10 analog input channels, configurable for 4-20 mA current loops, ±10 V voltages, or RTD/thermocouple inputs via jumpers and terminal board pairings. Each channel offers differential sensing with optical isolation up to 500 V, shielding sensitive measurements from noise in electrically busy turbine enclosures. The two analog outputs drive actuators or indicators with 14-16 bit resolution, ensuring smooth control responses during transients like load ramps or trips.

Hardware-wise, this board thrives in industrial panels thanks to its rugged VME form factor, low power draw from backplane supplies (+5 V and ±15 V rails), and status LEDs (RUN, FAIL, STAT) that give operators instant health checks without pulling it from the rack. Operating from 0 to 70°C, it shrugs off heat from nearby power converters while maintaining scan rates fast enough for 100 Hz cyclic updates on critical parameters. Mounting secures it firmly in 19-inch racks, with horizontal connectors simplifying cable management in dense I/O assemblies.

Performance shines in error tolerance: built-in diagnostics detect wire breaks, over/under-range conditions, and calibration drift, reporting them via the Mark VI network for proactive maintenance. Scan times around 10 ms keep pace with dynamic processes, while MTBF figures exceeding 200,000 hours underscore its fit for 20+ year turbine lifecycles. Compatibility extends to GE terminal boards like TBAIH1C, ensuring seamless signal routing without adapters.

Reliability comes from surface-mount components and conformal coating options that resist humidity and contaminants common in power plants. For teams standardizing on Mark VI, the GE IS200VAICH1CBB cuts spares complexity by supporting field-swappable revisions, backed by GE firmware that evolves with cybersecurity mandates.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | IS200VAICH1CBB |

| Brand | General Electric (GE) |

| Type | VME Analog Input/Output Card |

| Series | Speedtronic Mark VI Turbine Control |

| Analog Inputs | 10 differential channels (4-20 mA, ±5/10 V, RTD/TC configurable) |

| Analog Outputs | 2 channels (4-20 mA or 0-200 mA, isolated) |

| Resolution | 16-bit ADC / 14-bit DAC |

| Power Supply | +5 V DC @ 6 A, +15 V / -15 V from VME backplane |

| Operating Temperature | 0 to +70 °C (32 to 158 °F) |

| Mounting | VME rack, dual-slot |

| Dimensions | Standard VME: approx. 260 mm x 100 mm (10.2 x 3.9 in) |

| Weight | Approximately 2 kg (4.4 lbs) |

| Interfaces | Two horizontal connectors to terminal boards; VME bus |

| Status Indicators | RUN, FAIL, STAT LEDs |

| Isolation | 500 V channel-to-earth |

| Diagnostics | Wire-break, over-range, auto-zero |

- IS200VAICH1CBB

Related Modules or Compatible Units

IS200VAICH1D – Later revision with 20 inputs and 4 outputs, used in expanded I/O racks needing higher channel density.

IS200VAICH1C – Base version without BB suffix, interchangeable for legacy Mark VI upgrades with minor firmware tweaks.

IS200TBAIH1C – Matching terminal board for field wiring, providing screw terminals for the IS200VAICH1CBB‘s inputs.

IS200VCMI – VME core controller that processes data from the IS200VAICH1CBB, forming the Mark VI processing backbone.

IS200VAICH1DAB – Enhanced variant with improved resolution, suited for high-precision applications alongside CBB boards.

IS200EXDM1 – Expansion module for additional discrete I/O, often paired in racks with IS200VAICH1CBB analog handling.

IS200VAICH1B – Earlier generation compatible with older terminal boards, useful in mixed-revision Mark VI systems.

Installation Notes & Maintenance Best Practices

Before sliding the GE IS200VAICH1CBB into a VME rack, confirm backplane voltage stability and slot assignments to avoid bus conflicts with adjacent cards—Mark VI racks demand precise sequencing during power-up. Pair it with a compatible TBAI terminal board, routing shielded twisted-pair cables for inputs while maintaining 500 V isolation margins through proper grounding planes and separation from high-voltage lines. Cabinet airflow matters here; position it away from exhaust vents, and verify connector torque to prevent vibration-induced intermittents common in turbine halls.

Maintenance revolves around quarterly visual scans for dust buildup on PCBs and annual checks of calibration using ToolboxST diagnostics to catch drift in gain/offset values. Monitor FAIL/STAT LEDs during run-up, and log any open-circuit faults from field wiring—replace thermocouples or transmitters promptly to avoid skewed turbine protection. Firmware updates from GE should roll out during planned outages, cross-checked against system-wide compatibility to preserve trip logic integrity. Spares rotation every 5-7 years keeps MTBF projections solid without full module swaps.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626