Description

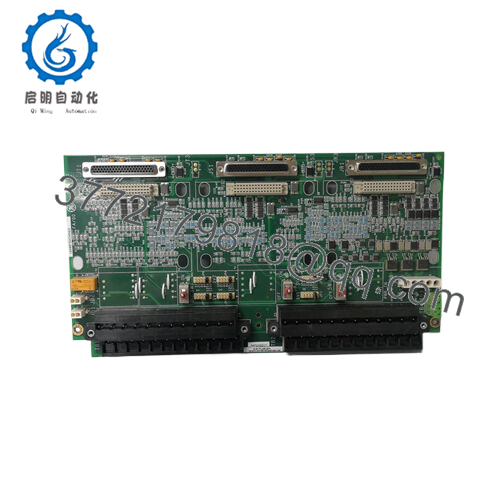

Product Model: GE IS200VCRCH1BBC

Product Brand: GE Industrial Solutions

Product Series: Mark VI IS200 Series

Product Features:

• Compact discrete input/output terminal board designed for Mark VI automation systems

• Accepts up to 48 discrete contact inputs and routes 24 relay/solenoid outputs via rack connections

• Single-slot board with front panel connectors for optimized rack space use

• Built-in LED status indicators (RUN, FAIL, STATUS) for quick diagnostics

Technical Specifications

| Specification | Detail |

|---|---|

| Product Model | GE IS200VCRCH1BBC |

| Series | Mark VI IS200 Series |

| Function | Discrete I/O Terminal Board |

| Discrete Inputs | Up to 48 contact inputs (via terminal boards) |

| Outputs | 24 relay/solenoid outputs (via rack connections) |

| Mounting | Single-slot backplane rack |

| Connectors | Backplane + front J33/J44 cable connectors |

| LEDs | RUN (green), FAIL (red), STATUS (orange) |

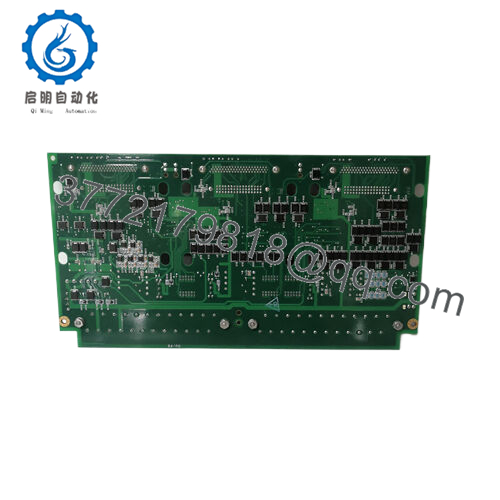

| Components | FPGAs, CMOS RAM, dual-port SRAM, test points |

| PCB Coating | Conformal / industrial grade |

| Revisions Supported | Backward revision compatibility |

- IS200VCRCH1BBC

Technical Features & Benefits

The GE IS200VCRCH1BBC integrates a range of practical features geared toward reliability, ease of maintenance, and long service life in industrial settings. At its core, this board processes discrete field signals — accepting 48 contact inputs and translating these into internal logic states that the CPU or supervisory controller can consume. Outputs are closely tied to rack-level termination, through which 24 relay/solenoid outputs are routed to actuators or indicators in the plant.

A defining feature of this board is its single-slot form factor, which both conserves valuable rack real estate and simplifies replacements in existing installations. Compared to broader variants that require daughterboards, the GE IS200VCRCH1BBC mounts efficiently while retaining full I/O functionality.

On the board’s faceplate, three LED indicators — RUN (green), FAIL (red), and STATUS (orange) — provide immediate visual feedback on operational state and diagnostic conditions. These indicators allow technicians to assess basic run status or fault conditions at a glance without immediate access to control system software.

Internally, the board’s electronic assembly comprises a dense array of components — including field-programmable gate arrays (FPGAs), static RAM, and CMOS circuits — that support stable and noise-resistant signal conditioning. Robust passive components like resistors, capacitors, and inductors further enhance signal integrity in electrically noisy environments typical of industrial racks.

Connectivity is designed with practicality in mind. Front-mounted cable connectors (J33 and J44) simplify access for field terminations, while backplane connectors ensure secure, reliable channel distribution to the central controller. This blend of front and rear connectivity, combined with test points for on-board troubleshooting, gives maintenance teams flexibility during installation or fault isolation.

Finally, the board’s compatibility across revisions — supporting backward connections for earlier revisions — means planners can upgrade select rack modules over time without complete system redesigns.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626