Description

The GE IS200VTURH2B is used anywhere gas or steam turbine protection, speed sensing, and flame detection have to work flawlessly together—typically in power plants running GE Speedtronic Mark VI systems and similar high-integrity turbine control architectures. In a combined-cycle plant, this board sits at the heart of the turbine protection chain: it watches shaft speed, supervises overspeed conditions, and monitors flame presence in each combustor to ensure the unit is either safely lit or safely shut down. In gas turbine packages for utilities, oil and gas, or industrial power generation, the GE IS200VTURH2B links real-world turbine behavior to the protection logic that decides when to trip, block starting, or allow loading.abb-sis+2

Consider a large-frame gas turbine starting on a cold morning. Multiple passive magnetic speed pickups on the shaft report speed at several points in the start sequence, while Geiger-Mueller flame detectors confirm that ignition energy actually produces a stable flame in each can or combustor. The GE IS200VTURH2B aggregates those inputs, compares them with defined limits, and signals trip hardware if speed overshoots or if flame disappears under conditions where it must be present. In applications without a mechanical overspeed bolt, this card effectively becomes the primary interface that can generate a high-integrity trip command to solenoids downstream. This is why it is widely used in industrial automation and directly applicable in control systems where safety, trip reliability, and fast response are non-negotiable.

Product introduction and positioning

The GE IS200VTURH2B is a VME Turbine Card, also referred to as a Primary Turbine Protection board, designed for the General Electric Speedtronic Mark VI series. Within this platform, it is a functional module dedicated to turbine protection and speed-related measurements rather than general-purpose I/O. It consolidates interfaces for shaft speed sensors, voltage and current feedback, and Geiger-Mueller flame detectors onto a single card, making it a specialized protection and monitoring hub for gas and steam turbines.

In a Mark VI cabinet, the GE IS200VTURH2B occupies a VME slot and connects to the system backplane, cooperating with backup protection modules and trip relay boards that act on its decisions. It is positioned between the harsh turbine environment—where sensors live near high temperatures and vibration—and the logic that commands fuel valves, trip solenoids, and breaker operations. By concentrating turbine-specific interfaces on this card, GE allows engineers to treat turbine protection as a clearly bounded subsystem with defined wiring, diagnostics, and testing procedures. That positioning makes the GE IS200VTURH2B particularly valuable for integrators and plant engineers who need to maintain or retrofit Mark VI-based protections without redesigning the entire control system.

- IS200VTURH2B

Key technical features and functional benefits

A defining strength of the GE IS200VTURH2B is its ability to process multiple high-integrity speed signals from passive magnetic sensors. It typically accepts four independent speed inputs, allowing redundant pickup configurations or separate monitoring of different turbine shafts or couplings. These inputs are conditioned and evaluated to support overspeed detection, speed matching, and other critical functions. Because the card is purpose-built for turbine speed measurement, it offers tight timing and robust signal conditioning, which reduces susceptibility to noise and provides stable, trustworthy speed values to the protection logic.

Another major function is flame detection. In gas turbine applications, the GE IS200VTURH2B interfaces with Geiger-Mueller flame detectors that verify whether combustion is present in each combustor. By monitoring the detector outputs and assessing whether the sensed light or radiation is blocked by carbon buildup, contamination, or misalignment, the board helps determine if a combustor is truly lit or should be considered failed and tripped. This ability to supervise multiple flame detectors makes it central to safe start-up and fuel transfer sequences and adds a diagnostic layer that operators can use when troubleshooting poor light-off or unstable combustion.

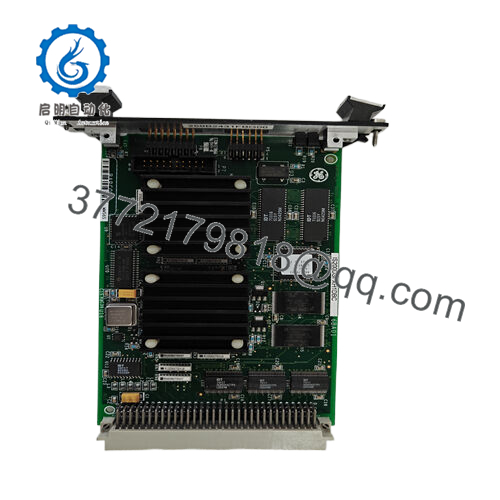

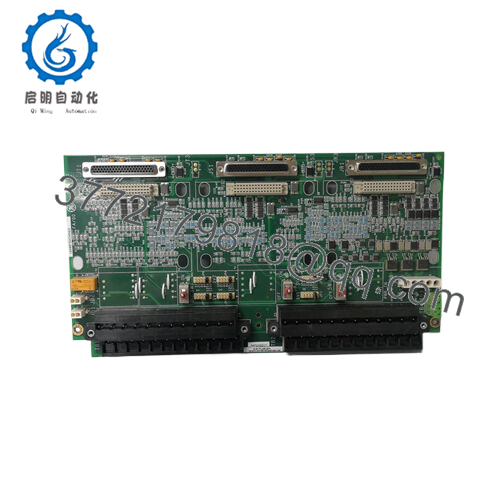

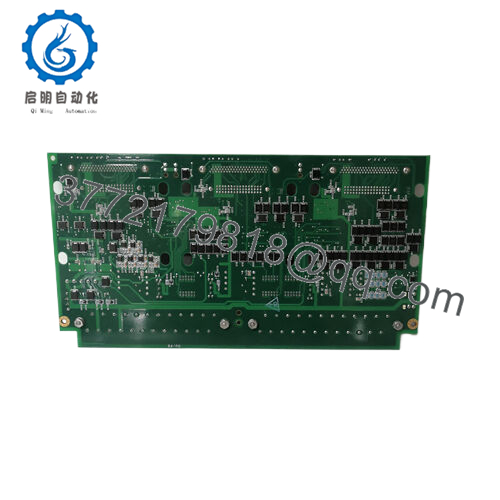

From a hardware perspective, the GE IS200VTURH2B uses a double-wide faceplate with a small set of essential components on the front: status LEDs and cable connectors that give technicians clear visual feedback and easy access during commissioning or fault finding. Three screws secure the faceplate to the board, improving mechanical stability in high-vibration turbine compartments. On the board itself, there are two backplane connectors and a dense population of inductors, capacitors, resistors, transistors, and integrated circuits including RAM, SRAM, oscillators, and FPGAs that execute its protection and interface tasks. An auxiliary board attached via standoffs provides additional backplane and interface functionality, all within a VME form factor that fits the wider Mark VI mechanical and electrical design.

Functionally, the GE IS200VTURH2B is also designed to work closely with backup protection I/O modules and trip relay boards. In turbines that do not use a mechanical overspeed bolt, it can generate a trip command to shut fuel and secure the unit if it detects overspeed or other critical conditions. That makes it central to meeting safety and compliance expectations for turbine overspeed protection. Because it is part of the Mark VI ecosystem, its diagnostic status, alarms, and test capabilities can be accessed from the system tools, which helps engineers validate its operation during periodic trip testing and tuning of protective setpoints.

Detailed technical specifications

| Parameter | Value |

|---|---|

| Model | GE IS200VTURH2B |

| Brand | General Electric (GE) |

| Type | VME Turbine Card / Primary Turbine Protection board |

| Control System Series | Speedtronic Mark VI |

| Primary Functions | Turbine speed monitoring, overspeed protection, flame detector interface |

| Speed Inputs | Four speed inputs from passive magnetic sensors |

| Flame Detector Interfaces | Multiple Geiger-Mueller flame detector channels (up to eight detectors typical) |

| Trip Capability | Can issue trip commands in applications without mechanical overspeed bolt |

| Physical Format | VME form factor with double-wide faceplate |

| Front-Face Features | LED status indicators and cable connectors |

| Backplane Connections | Two VME backplane connectors plus auxiliary backplane via daughter board |

| Typical Applications | Gas and steam turbine protection, shaft speed and flame monitoring |

Related modules or compatible units

GE IS200TPR0S1CBB – Processor/controller module in Mark VIe systems that can work with turbine-specific boards for integrated control and protection.

GE IS200ERBPG1A – Exciter regulator backplane board that interfaces with generator excitation systems protected and supervised by turbine control logic.

GE IS200STCIH6AED – Contact input board used in the same control environment to bring in discrete protection and status signals.

GE IS230TVBAH2A – Turbine-related I/O module that complements the GE IS200VTURH2B by handling additional vibration or process inputs.

GE IS200VCMIH2BCC – VME communications or control interface that links turbine protection boards to the rest of the Mark VI system network.

DS200FSAAG1ABA – Speedtronic-related control or protection board that can be used alongside the GE IS200VTURH2B in broader GE turbine control solutions.

Installation notes and maintenance best practices

When installing the GE IS200VTURH2B, engineers should verify that the VME rack and Mark VI backplane slot align with the card’s double-wide faceplate and dual connector arrangement. Careful attention to seating the backplane connectors is crucial, as poor engagement can produce intermittent speed or flame signals that mimic real faults. Speed pickup wiring from passive magnetic sensors should be routed with shielding and separation from high-current conductors to minimize induced noise, and each sensor polarity should be confirmed against documentation before energizing. Flame detector cables should be checked for insulation integrity and proper grounding, as these circuits are pivotal to reliable flame indication during startup and load changes.

For ongoing maintenance, the GE IS200VTURH2B benefits from a structured testing and inspection routine. Regular functional tests of overspeed protection and flame detection sequences, often carried out during planned outages, help verify that the board and its connected sensors still behave within expected limits. Visual inspections should include checking faceplate screws, connector integrity, and any signs of thermal stress or contamination on the board edge. Since the module plays a critical role in trip decisions, many users adopt a strategy of periodic calibration or verification of speed pickups and detectors, alongside reviewing diagnostic logs for any intermittent speed dropouts or flame signal fluctuations. Keeping spare units on hand and maintaining up-to-date configuration and test records ensures that, if replacement is required, the GE IS200VTURH2B can be swapped and validated quickly with minimal impact on turbine availability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626