Description

The GE IS200WETCH1AAA addresses a key challenge in Mark VI turbine control systems: delivering clean, regulated, and distributed power to auxiliary circuits, sensors, and logic components in environments where input sources vary widely or carry noise from generators, inverters, or long cable runs. In gas and steam turbine setups using GE’s Speedtronic Mark VI platform, power quality issues—such as ripple, transients, or insufficient isolation—can degrade signal accuracy, cause erratic relay behavior, or interrupt critical monitoring loops, leading to reduced diagnostic reliability, false alarms, or even protective trips that halt production unnecessarily.

These problems are common in power generation plants with aging infrastructure, retrofits, or high-electrical-noise areas near exciters and large motors, where standard supplies fall short in maintaining stable voltages across multiple loads. The GE IS200WETCH1AAA counters this as a specialized converter power module (sometimes described as a “top box” or auxiliary power distribution board) within the Mark VI family. It converts and conditions incoming power to provide multiple isolated, regulated outputs tailored for turbine auxiliaries, ensuring high-reliability operation that keeps the focus on precise turbine sequencing, protection, and performance monitoring rather than battling upstream power inconsistencies.

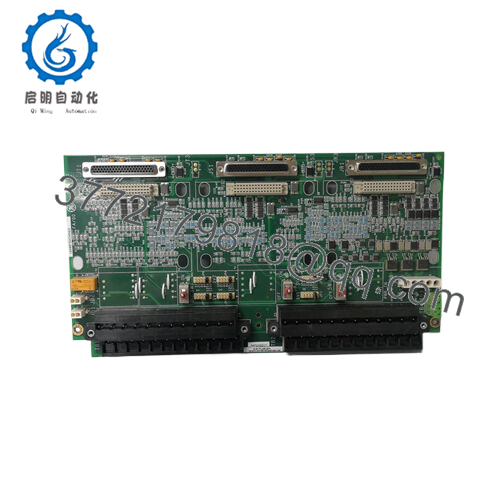

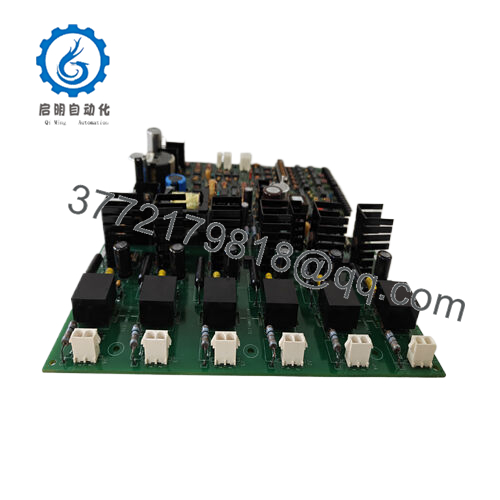

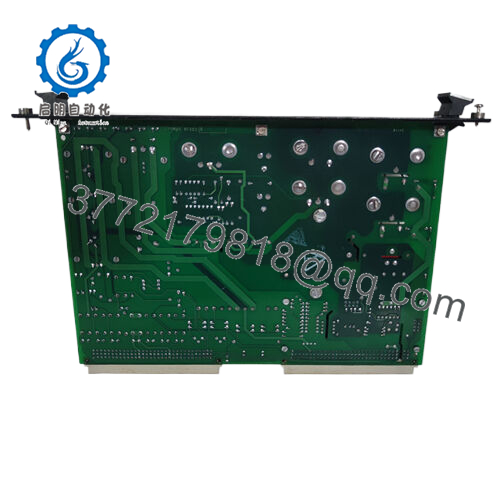

GE IS200WETCH1AAA operates as a compact, rack- or panel-mounted power conditioning and distribution board in GE Mark VI Speedtronic architectures, typically installed in control cabinets, I/O racks, or near processor modules to supply clean power to discrete I/O, analog circuits, relays, and communication interfaces. It features input acceptance from common turbine DC links or AC-derived sources, then uses onboard transformers, regulators (with numerous voltage regulators noted in its design), inductors, capacitors, diodes, and fuses to generate stable outputs—often including isolated rails for sensitive logic and excitation needs.

The board interfaces via terminal strips (typically two with multiple positions for input/output wiring) and connectors, routing conditioned power while incorporating protective elements like four fuses in paired sets, a transformer for isolation, and heat-dissipating components to handle thermal loads. Positioned in the power supply subsystem of the Mark VI stack, it supports both simplex and TMR configurations by providing dependable distribution without active control logic, allowing seamless integration with higher-level processors, I/O packs, and field devices. This passive-yet-robust approach minimizes points of failure, reduces wiring complexity in crowded panels, and aligns with the modular, expandable nature of Mark VI systems for reliable industrial automation in demanding turbine environments.

- IS200WETCH1AAA

| Specification | Details |

|---|---|

| Model Number | IS200WETCH1AAA |

| Brand | GE (General Electric) |

| Type | Converter Power Module / Auxiliary Power Distribution Board |

| Input Voltage | Flexible DC/AC sources (typical Mark VI ranges; exact per system design) |

| Operating Temp Range | Typically -20°C to +60°C (Mark VI standard; cabinet-dependent) |

| Mounting Style | Rack or panel mounted (PCB with terminal strips) |

| Dimensions | Approx. 26 cm × 19 cm × 2–5 cm (compact Mark VI form factor) |

| Weight | Approx. 0.3–0.5 kg |

| Interface/Bus | Terminal strips (multiple positions); connectors for power distribution |

| Compliance | Industrial ruggedized; CE typical for Mark VI series |

| Supported Protocols | N/A (power module; integrates with Mark VI internal bus and IONet via system) |

| Typical Power Draw | Dependent on load; efficient regulation with low inherent consumption |

Selecting the GE IS200WETCH1AAA provides substantial value in turbine control by ensuring stable, isolated power delivery that enhances overall system dependability and diagnostic accuracy. Its multi-regulator design and protective features guard against voltage excursions, supporting consistent performance for relays, sensors, and logic circuits even during grid disturbances or startup transients—resulting in fewer spurious events and greater operator trust in protective functions.

The module reduces integration effort in Mark VI deployments or upgrades, with straightforward terminal access and compatibility that shortens commissioning while minimizing custom power conditioning needs. Over extended service, its rugged construction withstands vibration, temperature cycles, and electrical stress common in power plants, lowering maintenance frequency and contributing to higher availability. In short, GE IS200WETCH1AAA helps optimize lifecycle costs by shifting focus from power-related anomalies to proactive turbine efficiency and reliability improvements.

GE IS200WETCH1AAA finds primary use in gas and steam turbine facilities within utility-scale power generation, including combined-cycle, base-load, and peaking plants where Mark VI controls handle sequencing, monitoring, and protection. It distributes conditioned power to auxiliary circuits critical for flame detection, vibration monitoring, or valve actuation, maintaining critical system uptime in noisy, high-vibration turbine halls.

It’s also deployed in industrial cogeneration or mechanical drive applications in oil & gas and petrochemical sectors, supporting reliable power for control loops in process control environments that demand uninterrupted operation under variable loads and harsh conditions. In these settings, GE IS200WETCH1AAA upholds signal and logic stability essential for safe, efficient turbine performance.

For related options within the Mark VI family or similar power/conditioning roles, consider these:

IS200WETCH1APR2 – Wind energy variant with adaptations for renewable turbine applications.

IS200WETBH1BAA – Related power distribution or conditioning board in the WET series for auxiliary needs.

IS200WETAH1AEC – Alternate revision or variant focused on specific power conversion tasks.

IS200WEMAH1ACA – Enhanced module for broader auxiliary management in Mark VI setups.

IS200CPFPG1AAA – Control power supply or fuse/protection board that complements this in racks.

IS200BPIHH1AAA – Bridge/interface power board for integration in exciter or control power paths.

IS200AVGAG1A – Gate driver or amplifier power-related board in turbine systems.

IS200DAMBG1A – Driver/amplifier module often paired for power handling in Mark VI.

Before installing GE IS200WETCH1AAA, confirm input source specifications (voltage range, polarity, and grounding) match your Mark VI cabinet design to prevent overload or instability. Verify terminal strip assignments against GE wiring diagrams for correct power routing, and ensure adequate ventilation around regulators and the transformer—maintain clearances for heat dissipation and cable management. Check system-level power coordination with processors or I/O packs, though this module requires no firmware or configuration.

For ongoing maintenance, inspect terminals and fuses visually during scheduled outages for signs of overheating, corrosion, or looseness, especially in dusty or humid conditions. Use a multimeter to verify output voltages periodically, and clean dust from components annually to sustain thermal performance. Monitor Mark VI diagnostics for any power-related faults that might indicate issues upstream or at this board—these routine steps fit standard preventive practices and help preserve stable distribution with minimal downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626